Chirality mesoporous organic polymer material with even and adjustable diameter and method for producing the same

An organic polymer and uniform technology, applied in the field of chiral mesoporous organic polymer materials and their preparation, can solve problems such as achiral structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

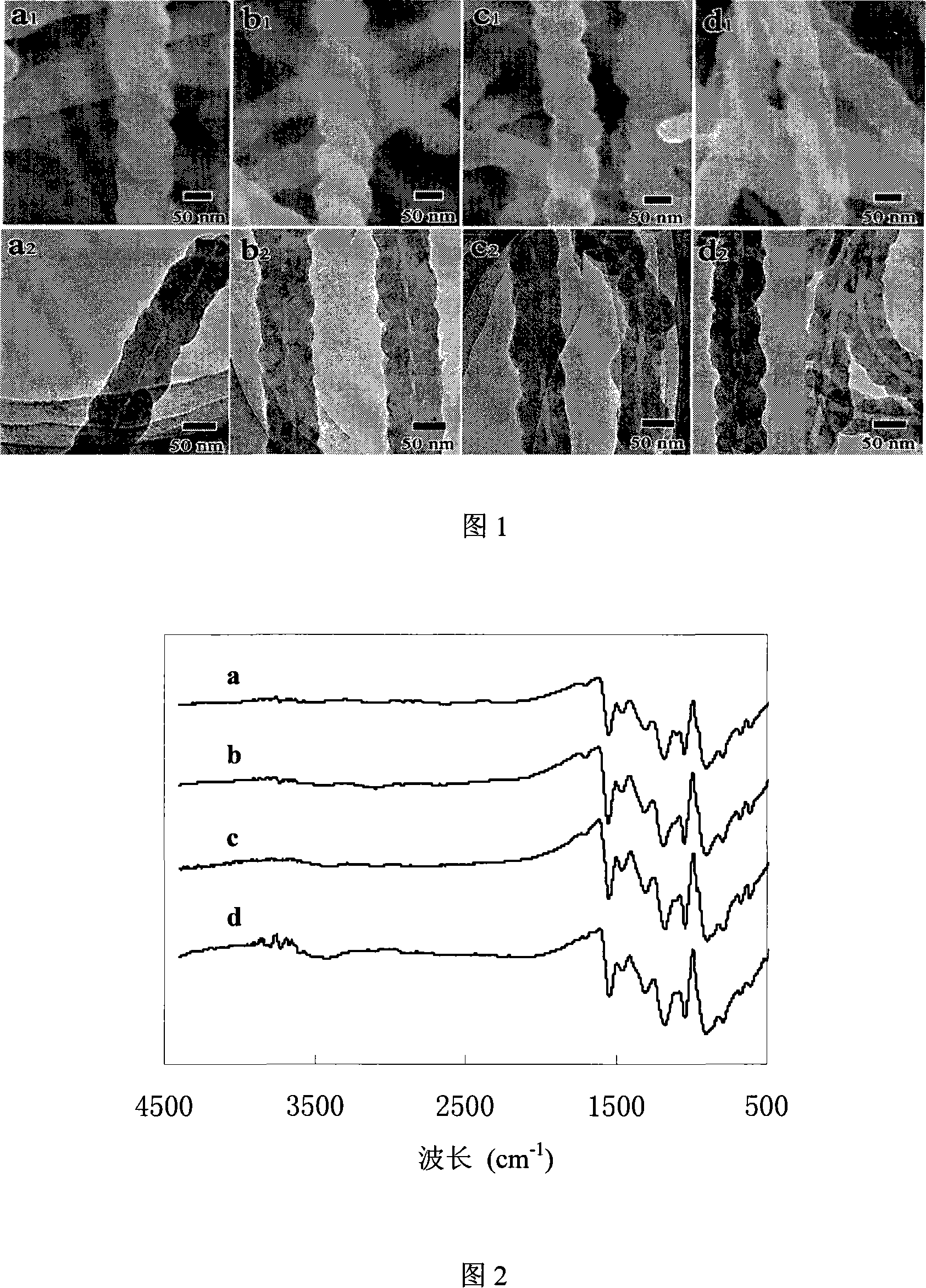

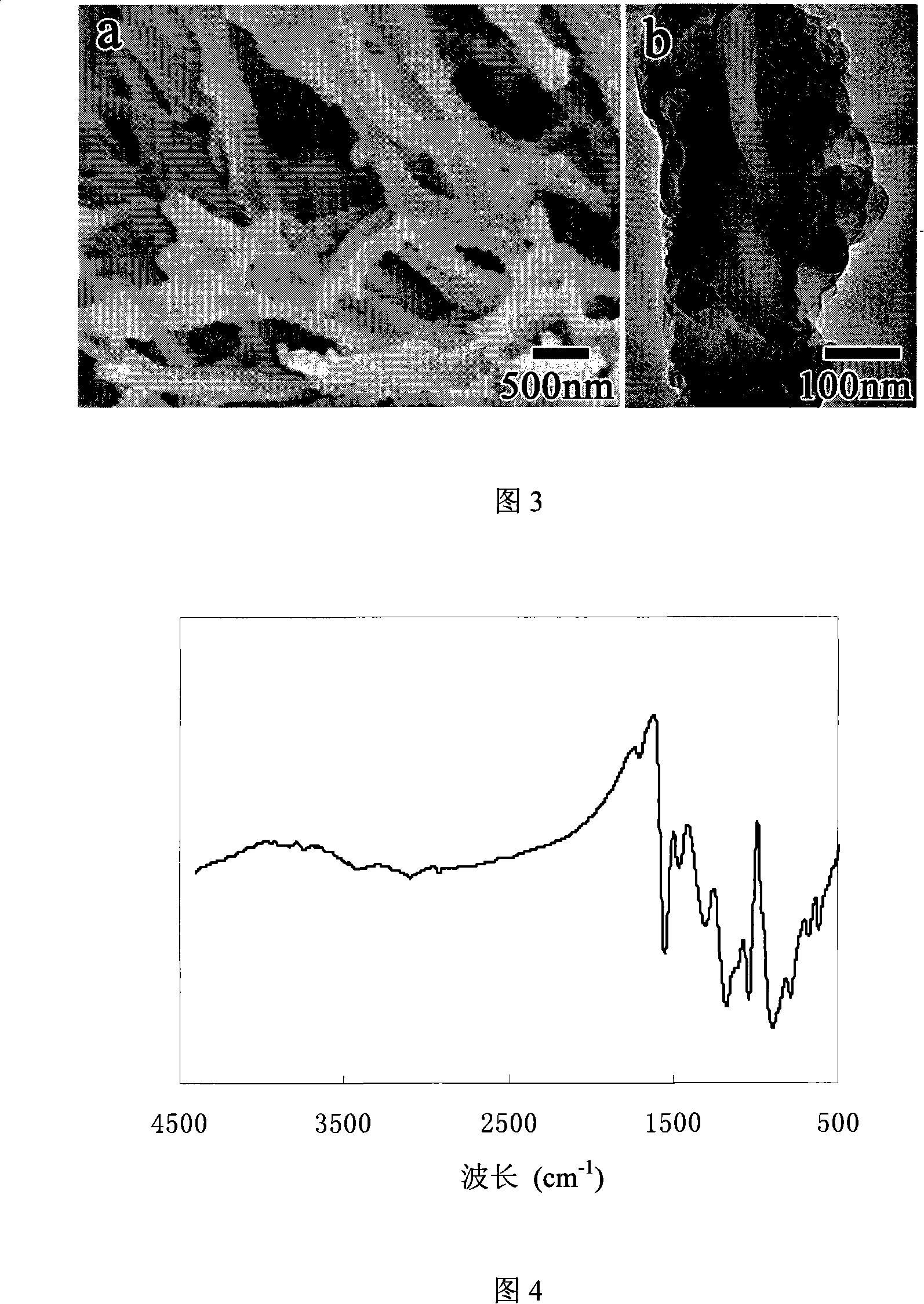

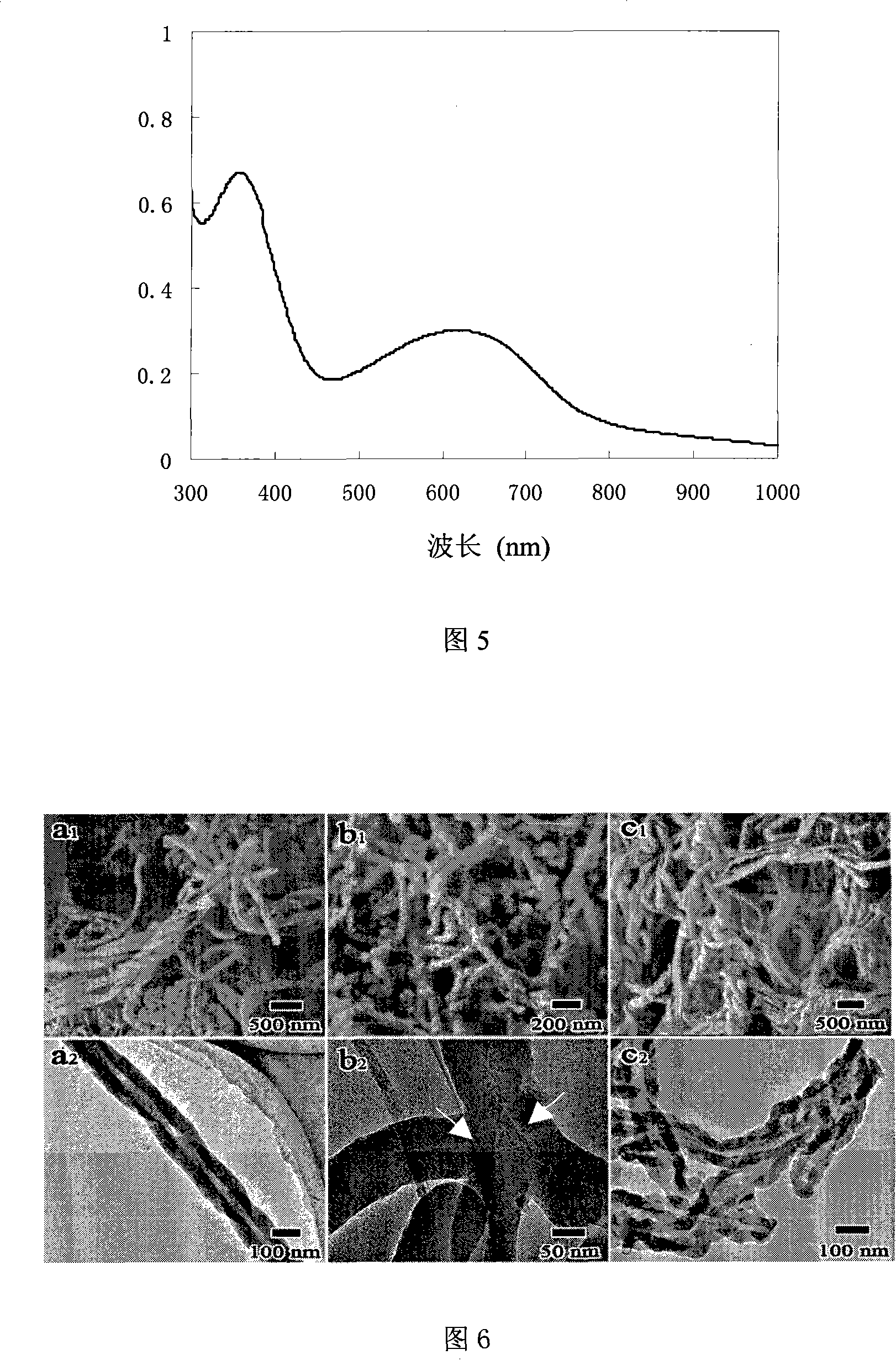

[0031] Dissolve 0.0033g (0.01mmol) of N-dodecyl-L-glutamic acid in 2.0g of absolute ethanol, add 10.0g of deionized water and 0.134g (2mmol) of pyrrole monomer at 0°C Stir for 5 min; then add 2.0 g (2 mmol) of 1.0 M hydrochloric acid solution and 1.456 g (2 mmol) of ammonium persulfate solution (0.456 g of ammonium persulfate dissolved in 1 g of deionized water), and stir at 0°C for 30 min to react and polymerize. After filtering, washing with deionized water three times, and vacuum drying at 40° C. for 12 hours, a chiral mesoporous polypyrrole with uniform and adjustable diameter was obtained. The obtained chiral mesoporous polypyrrole is a mesoporous tube with the same helical structure in the channel and the outer surface. The tube length of the material is 2-5μm, the inner diameter of the tube is 5.4nm, the thickness of the tube wall is 50nm, the pitch is 85nm, and the specific surface area is 44.0m 2 g -1 , the hole volume is 140mm 3 g -1 .

[0032] A in Fig. 1 is th...

Embodiment 2

[0035] Dissolve 0.0036g (0.01mmol) of N-tetradecanoyl-L-glutamic acid in 2.0g of absolute ethanol, add 10.0g of deionized water and 0.134g (2mmol) of pyrrole monomer at 0°C Stir for 5 min; then add 2.0 g (2 mmol) of 1.0 M hydrochloric acid solution and 1.456 g (2 mmol) of ammonium persulfate solution (0.456 g of ammonium persulfate dissolved in 1 g of deionized water), and stir at 0°C for 30 min to react and polymerize. After filtering, washing with deionized water three times, and vacuum drying at 40° C. for 12 hours, a chiral mesoporous polypyrrole with uniform and adjustable diameter was obtained. The obtained chiral mesoporous polypyrrole is a mesoporous tube with the same helical structure in the channel and the outer surface. The tube length of the material is 5-10 μm, the tube inner wall diameter is 9.0 nm, the tube wall thickness is 45 nm, the screw pitch is 100 nm, and the specific surface area is 45.9 m 2 g- 1 , the hole volume is 130mm 3 g -1 .

[0036] b in Fi...

Embodiment 3

[0039] Dissolve 0.0039g (0.01mmol) of N-hexadecyl-L-glutamic acid in 2.0g of absolute ethanol, add 10.0g of deionized water and 0.134g (2mmol) of pyrrole monomer at 0°C Stir for 5 min; then add 2.0 g (2 mmol) of 1.0 M hydrochloric acid solution and 1.456 g (2 mmol) of ammonium persulfate solution (0.456 g of ammonium persulfate dissolved in 1 g of deionized water), and stir at 0°C for 30 min to react and polymerize. After filtering, washing with deionized water three times, and vacuum drying at 40° C. for 12 hours, a chiral mesoporous polypyrrole with uniform and adjustable diameter was obtained. The obtained chiral mesoporous polypyrrole is a mesoporous tube with the same helical structure in the channel and the outer surface. The tube length of the material is 10-15 μm, the inner diameter of the tube is 10.9 nm, the tube wall thickness is 35 nm, the screw pitch is 100 nm, and the specific surface area is 54.5 m 2 g -1 , the hole volume is 210mm 3 g -1 .

[0040] C in Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com