Carbon-carried multi-metal polypyrrole oxygen reduction catalyst and preparation method thereof

A polypyrrole and catalyst technology, applied in carbon-supported polypyrrole-based oxygen reduction catalyst and preparation thereof, in the field of catalyst research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

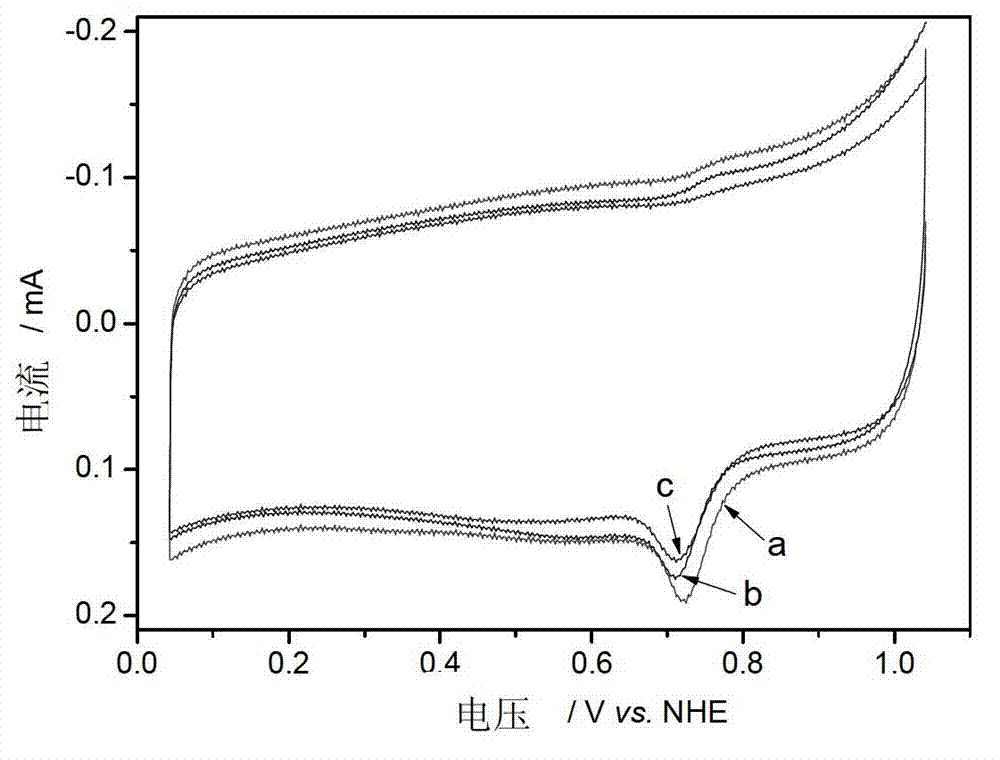

[0023] Embodiment 1: three-step synthetic method

[0024] Weigh 0.6g of Black Pears 2000 (BP2000) carbon black, add it into a conical flask containing 100ml of isopropanol, ultrasonically disperse it for 30min, add 3mmol of pyrrole and 100ml of double distilled water, stir for 30min, then add 100ml of 0.06mol / L of ammonium persulfate (APS) solution and 0.19 g of p-toluenesulfonic acid (TsOH), filtered after polymerization for 4 hours, washed repeatedly with absolute ethanol and double distilled water, and dried at 45°C for 12 hours. Add 0.5 g of the resulting product, 0.134 g of cobalt acetate tetrahydrate and 0.107 g of ferric nitrate nonahydrate into an Erlenmeyer flask filled with 200 ml of double-distilled water, ultrasonically disperse for 1 h and then stir for 2 h, then transfer to a round-bottomed flask and place at constant temperature The solvent was evaporated to dryness by rotary evaporation in a water bath. Then the obtained product was transferred to a quartz bo...

Embodiment 2

[0026] Embodiment 2: three-step synthetic method

[0027] Weigh 0.6g of Black Pears 2000 (BP2000) carbon black, add it into a conical flask containing 100ml of isopropanol, ultrasonically disperse it for 30min, add 3mmol of pyrrole and 100ml of double distilled water, stir for 30min, then add 100ml of 0.06mol / L of ammonium persulfate (APS) solution and 0.19 g of p-toluenesulfonic acid (TsOH), filtered after polymerization for 4 hours, washed repeatedly with absolute ethanol and double distilled water, and dried at 45°C for 12 hours. Add 0.5 g of the resulting product, 0.174 g of cobalt acetate tetrahydrate and 0.02 g of copper acetate monohydrate into a conical flask filled with 200 ml of double-distilled water, ultrasonically disperse for 1 h, then stir for 2 h, then transfer to a round-bottomed flask, and place at a constant temperature The solvent was evaporated to dryness by rotary evaporation in a water bath. Then the obtained product was transferred to a quartz boat an...

Embodiment 3

[0029] Embodiment 3: three-step synthetic method

[0030] Weigh 0.6g of Black Pears 2000 (BP2000) carbon black, add it into a conical flask containing 100ml of isopropanol, ultrasonically disperse it for 30min, add 3mmol of pyrrole and 100ml of double distilled water, stir for 30min, then add 100ml of 0.06mol / L of ammonium persulfate (APS) solution and 0.19 g of p-toluenesulfonic acid (TsOH), filtered after polymerization for 4 hours, washed repeatedly with absolute ethanol and double distilled water, and dried at 45°C for 12 hours. Add 0.5 g of the resulting product, 0.242 g of ferric nitrate nonahydrate and 0.05 g of manganese nitrate tetrahydrate into an Erlenmeyer flask filled with 200 ml of double distilled water, ultrasonically disperse for 1 h and then stir for 2 h, then transfer to a round-bottomed flask and place at constant temperature The solvent was evaporated to dryness by rotary evaporation in a water bath. Then the obtained product was transferred to a quartz ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com