Anchor clipper through hole type workblank cold pressing technique

A technology of cold extrusion and blank, which is applied in the field of cold extrusion process of through-hole blank of anchor clips, can solve the problems of low material utilization rate, high cost of clips, large machining amount, etc., so as to reduce the amount of machining. , the effect of high material utilization and saving rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Basic technology of the present invention is:

[0025] After selecting the round bar stock:

[0026] (1), blanking, if necessary, cut the round steel into the required length;

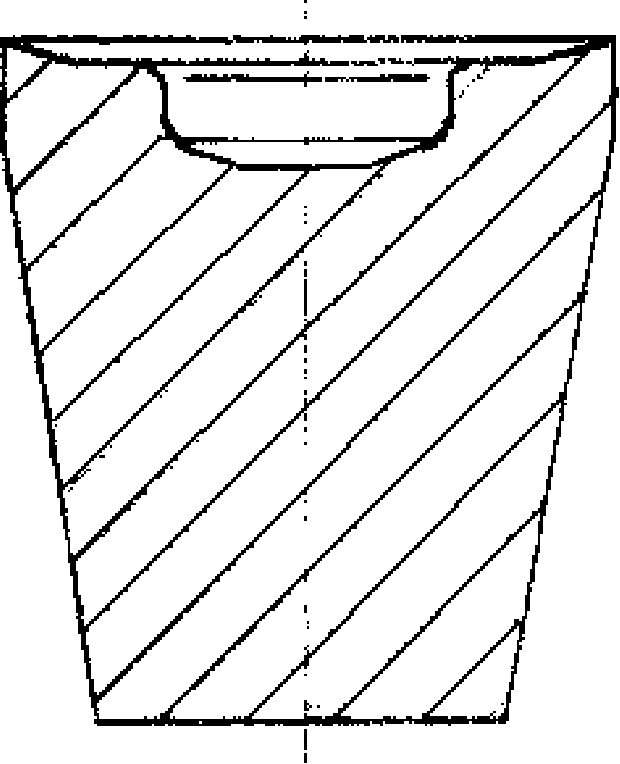

[0027] (2), preforming, preforming the cold extruded bar blank with a punching machine;

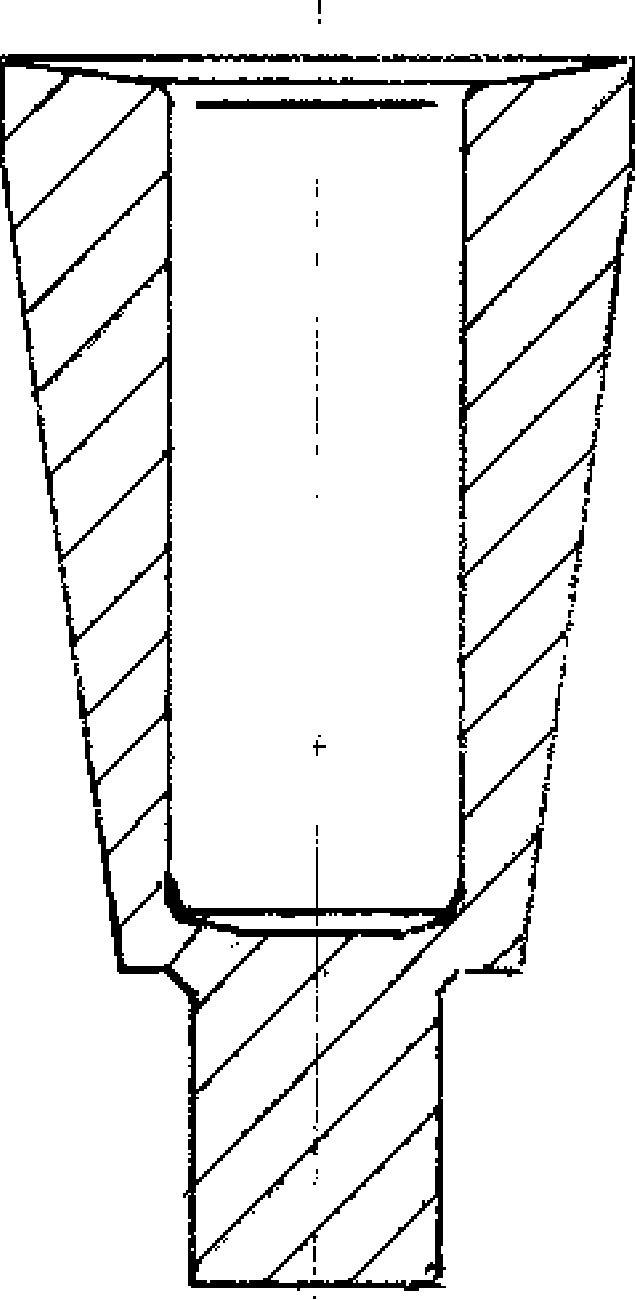

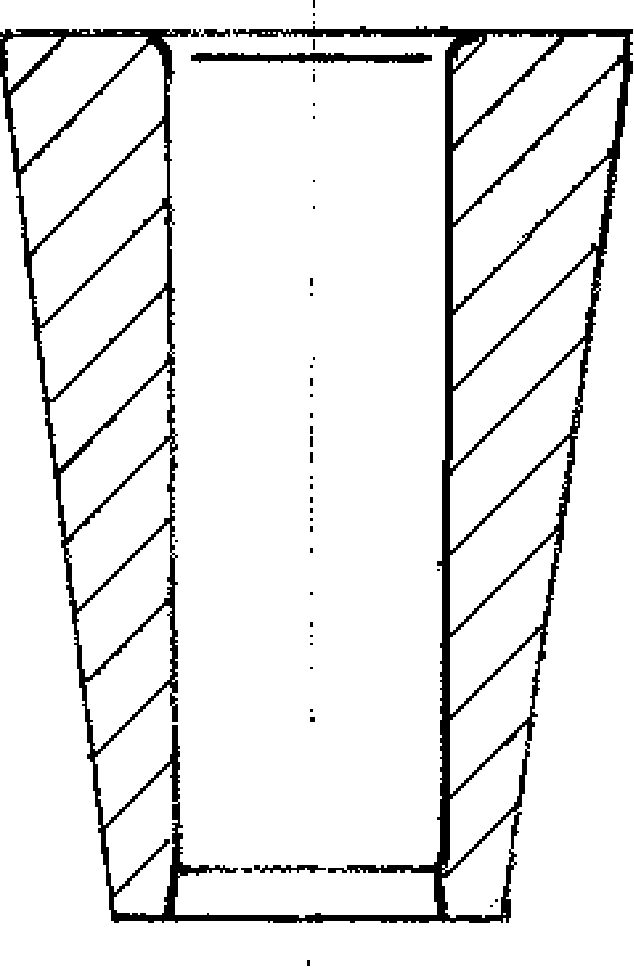

[0028] (3), extrusion molding, carry out cold extrusion molding to the preformed blank with punching machine;

[0029] (4) Punching and forming, punching the extrusion forming blank with a punching machine, and forming by upsetting.

[0030] In this embodiment, the following basic steps are added:

[0031] Phosphating saponification treatment or organic polymer lubricant treatment is carried out between blanking and preforming steps.

[0032] Before phosphating and saponification treatment or organic polymer lubricant treatment, perform sandblasting treatment or pickling and water washing treatment.

[0033] Perform normalizing treatment between the preforming and extrusion molding steps, heat in a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com