Three-frequency bad high-performance frequency selection surface based on adjacent unit micro interference

A frequency-selective surface and high-performance technology, applied in the microwave field, can solve problems such as complex structure, difficult design, and inability to design quickly and effectively, and achieve the effects of improving selection performance, enhancing bandwidth stability, and improving frequency selection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

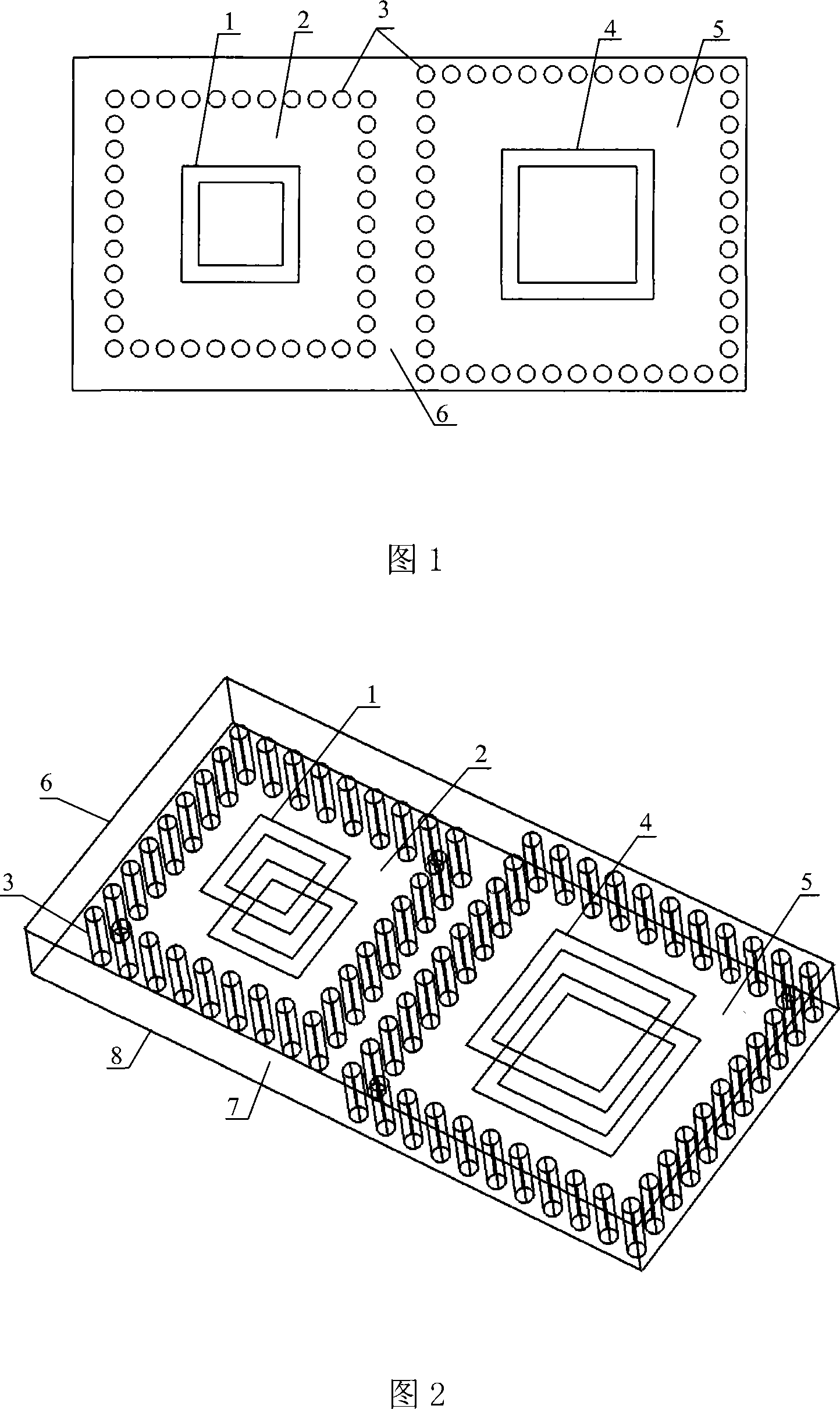

[0018] As shown in Figures 1 and 2, the three-band high-performance frequency selective surface based on adjacent unit perturbation includes a Rogers5880 dielectric substrate 7 with a thickness of 1.0 mm, and the two sides of the dielectric substrate 7 are coated with metal layers, which are respectively the upper metal layer 6 and the lower metal layer 8 . Through the upper metal layer 6 , the dielectric substrate 7 and the lower metal layer 8 , multiple groups of through holes with a diameter of 0.8 mm are periodically opened, and the inner walls of the through holes are plated with a metal layer to form metallized through holes 3 . Each group of metallized through holes 3 is arranged as two adjacent squares, respectively forming a high-frequency substrate-integrated waveguide cavity 2 with a side length of 19.1 mm and a low-frequency substrate-integrated waveguide cavity 5 with a side length of 23.3 mm. The hole spacing of the metallized through holes 3 on each side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com