Micro-fluidic chip and its preparation and uses

A microfluidic chip and chip technology, applied in chemical instruments and methods, material testing products, solid adsorbent liquid separation, etc., can solve the problem of limited polymerization reaction system, difficult positioning of the monolithic column for thermally induced polymerization, and organic solvent resistance. Problems such as poor sex, to achieve the effect of a simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

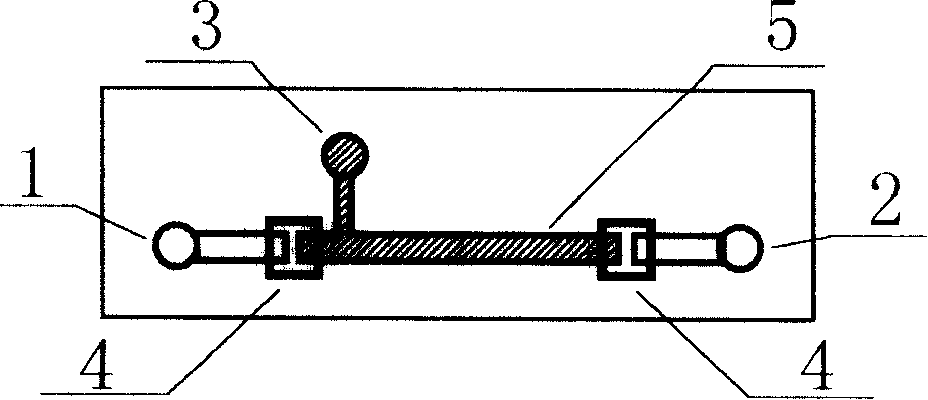

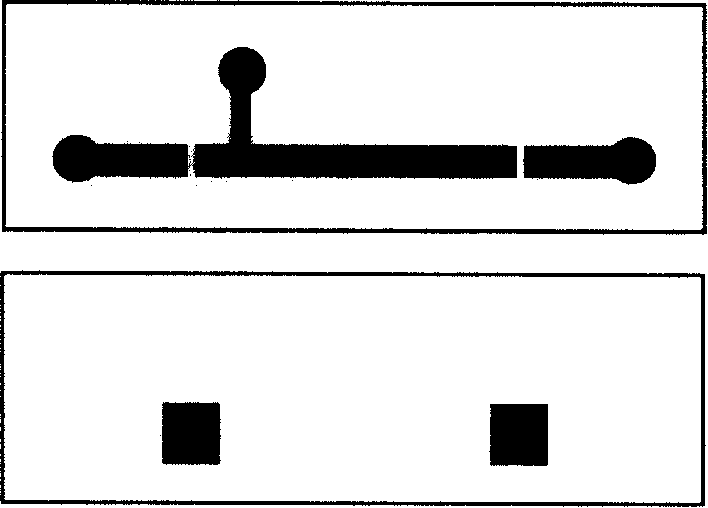

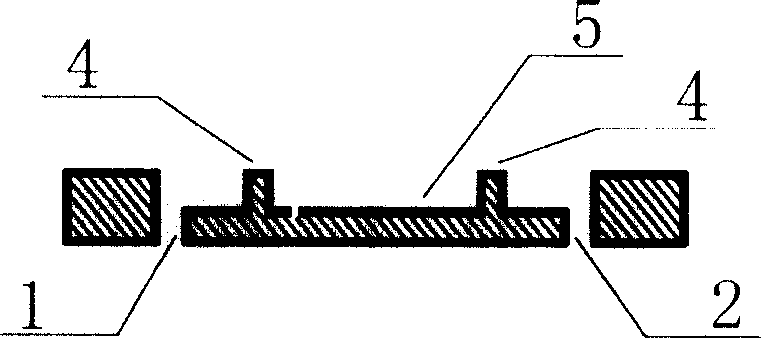

[0025] Such as figure 1 As shown, a microfluidic chip is formed by sealing the upper and lower two-layer substrates. The upper substrate is provided with a sample inlet 1, a sample outlet 2 and a microchannel. The microchannel of the upper substrate A microparticle introduction channel and its inlet 3 are provided on the top, and a dam structure is respectively provided between the inlet 3 of the microparticle introduction channel, the sample inlet 1 and the sample outlet 2, and the two dam structures form a double cofferdam structure 4, two The microchannel between the two dam structures forms the packed column bed channel 5; the position corresponding to the dam structure on the lower substrate is respectively provided with a microchannel, and there is a gap between the top surface of the dam structure and the microchannel of the lower substrate; The depth of the slot is smaller than the depth of the microchannels in the upper substrate.

[0026] Fabrication of microfluidic...

Embodiment 2

[0034] Example 2 The chip SPE column filled with unmodified silica gel (diameter 5 μm) is used for the extraction of λ-DNA

[0035] The loading, washing and elution buffers used in this example were 6M guanidine hydrochloride (dissolved in 10mM Tris-1mM EDTA buffer, pH 6.1), 80% isopropanol in water and TE buffer (10mM Tris-1mM EDTA , pH 7.5); the sample used for extraction was λ-DNA dissolved in loading buffer (final concentration was 0.5 ng / μL). The self-made chip interface was used to connect the SPE chip to the syringe pump, and the flow rate was controlled at 3 μL / min; the volumes of the sample loading, washing and eluting solutions used were 12 μL, 15 μL and 15 μL, respectively, and the entire chip extraction process took less than 15 minutes. Eluted DNA samples were collected and quantified fluorophotometrically using intercalating fluorescent dyes to determine the extraction efficiency and reproducibility of this chip SPE method.

[0036] From the experimental results...

Embodiment 3

[0037] Example 3 The chip SPE column filled with silica gel is used to purify genomic DNA from actual samples

[0038] The sample used in this example is a human whole blood sample, and the processing method is as follows: 4.6 μL whole blood sample is dissolved in 500 μL loading buffer (6M guanidine hydrochloride, 10 mM Tris-1 mM EDTA buffer, pH 6.1), and then 10 μL proteinase K is added (20mg / mL), and then kept in a 56°C water bath for 10 minutes to obtain a sample solution for extraction. The volumes of loading, washing and elution solutions used were 15 μL, 20 μL and 15 μL, respectively, and the flow rate was 3 μL / min. The eluted DNA samples were collected in 5 μL aliquots, and 2.5 μL in each aliquot was used for PCR amplification. The primer sequences used are:

[0039] 5'-AACTGTTGCTTTATAGGATTTT-3' (sense strand),

[0040] 5'-AGGAGCTTATTGATAACTCAGAC-3' (antisense strand);

[0041] The amplified product is a 650bp fragment of the human genome β-globin gene. The composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com