Engagement type controlled non-contact wedge backstop

A backstop, non-contact technology, applied in the direction of brake type, conveyor control device, conveyor objects, etc., can solve the increase of backstop cost and daily maintenance, high contact stress on contact surfaces, and difficult backstop oil leakage And oil seepage and other problems, to achieve the effect of reducing daily maintenance, low cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

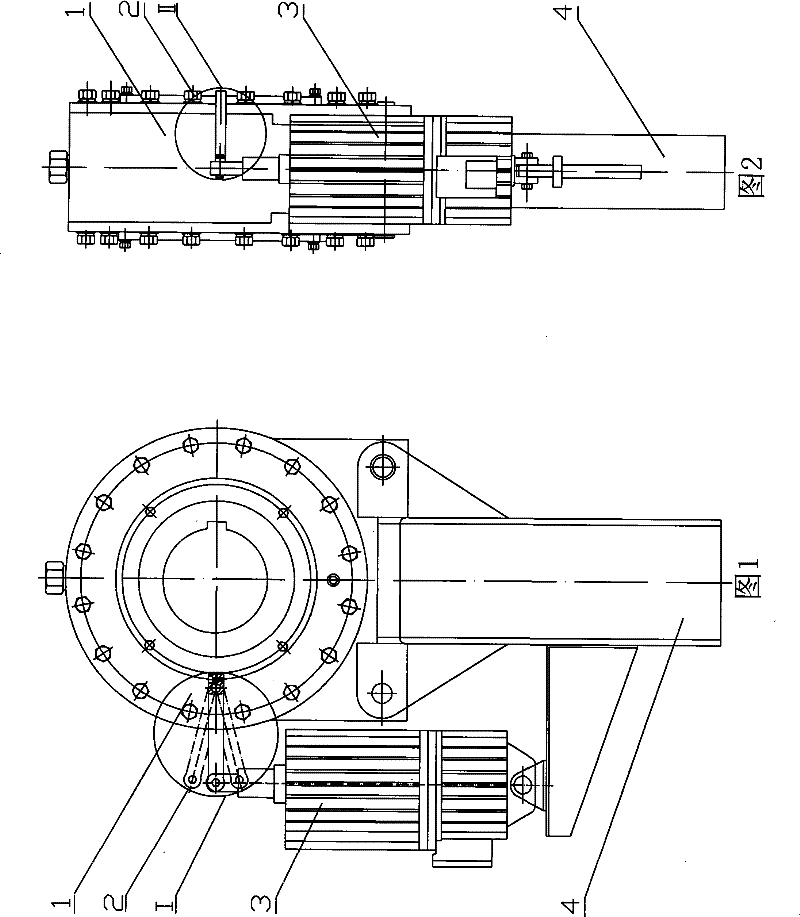

[0039] Referring to Fig. 1 and Fig. 2, an engaging controllable non-contact wedge backstop mainly consists of a backstop component 1, an engaging element 2, a controller 3, an anti-rotation arm 4, a wedge assembly 5, etc. Parts and components; the backstop component 1 is installed on the top surface of the anti-rotation arm 4, the controller 3 is installed on the anti-rotation arm 4, and is connected in series with the main machine of the conveying equipment such as belt conveyor or bucket elevator, and the engaging element 2 Connect with backstop component 1 and controller 3, controller 3 is prior art, can adopt any one of electromagnetic mechanism, electric hydraulic pusher, pneumatic or hydraulic pusher etc.

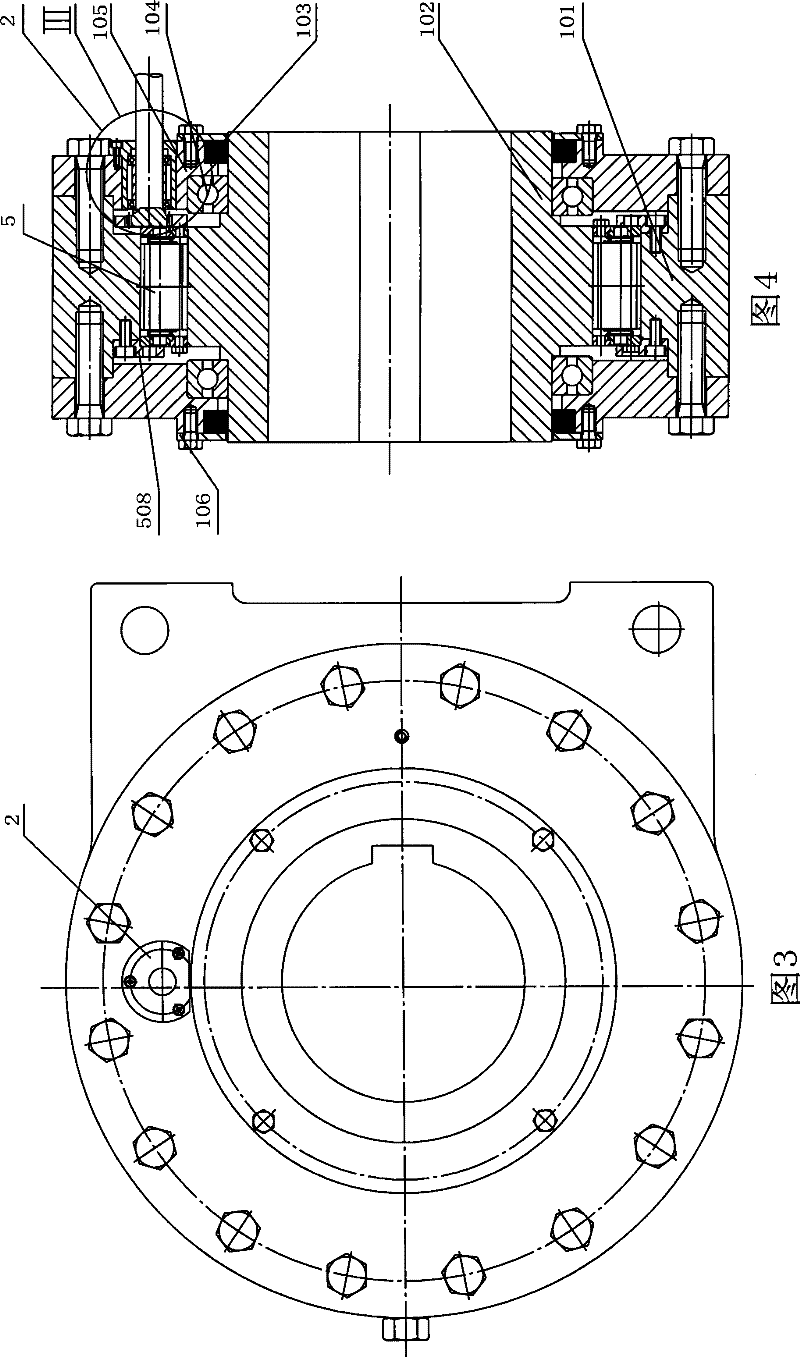

[0040] Referring to Fig. 3 and Fig. 4 at the same time, the backstop component 1 includes components such as an outer ring 101, an inner ring 102, a sealing ring 103, a bearing 104, an end cover 105, and a cover plate 106; A rolling bearing 104 and a sealing ring 103 ...

Embodiment 2

[0044] Referring to Fig. 10, Fig. 11, Fig. 12, and Fig. 13, the engaging element 2 can also protrude from the circumference of the end cover 105 of the backstop component 1 to connect with the controller 3 through an additional wheel shaft.

[0045] Referring to Fig. 14, Fig. 15, shown in Fig. 16 at the same time, described meshing element 2 also comprises components such as intermediate gear 207, intermediate gear shaft or rack 208, key 209; The intermediate gear 207 is connected by a key 209, the intermediate gear 207 meshes with the intermediate gear shaft or the rack 208, and one end of the intermediate gear shaft or the rack 208 is connected from the end cover 105, which can be a circular hole or a circular hole on the circumference of the front end cover or the rear end cover. Protrude from the long hole and use sealing ring or wool sticky, packing seal, connect with controller 3 through connecting rod 203; All the other structures of embodiment 2 are the same as embodim...

Embodiment 3

[0047] Referring to Fig. 17, Fig. 18, Fig. 19, and Fig. 20, the engaging element 2 can also protrude from the circumference of the end cover 105 of the backstop component 1 to connect with the controller 3 through an additional camshaft.

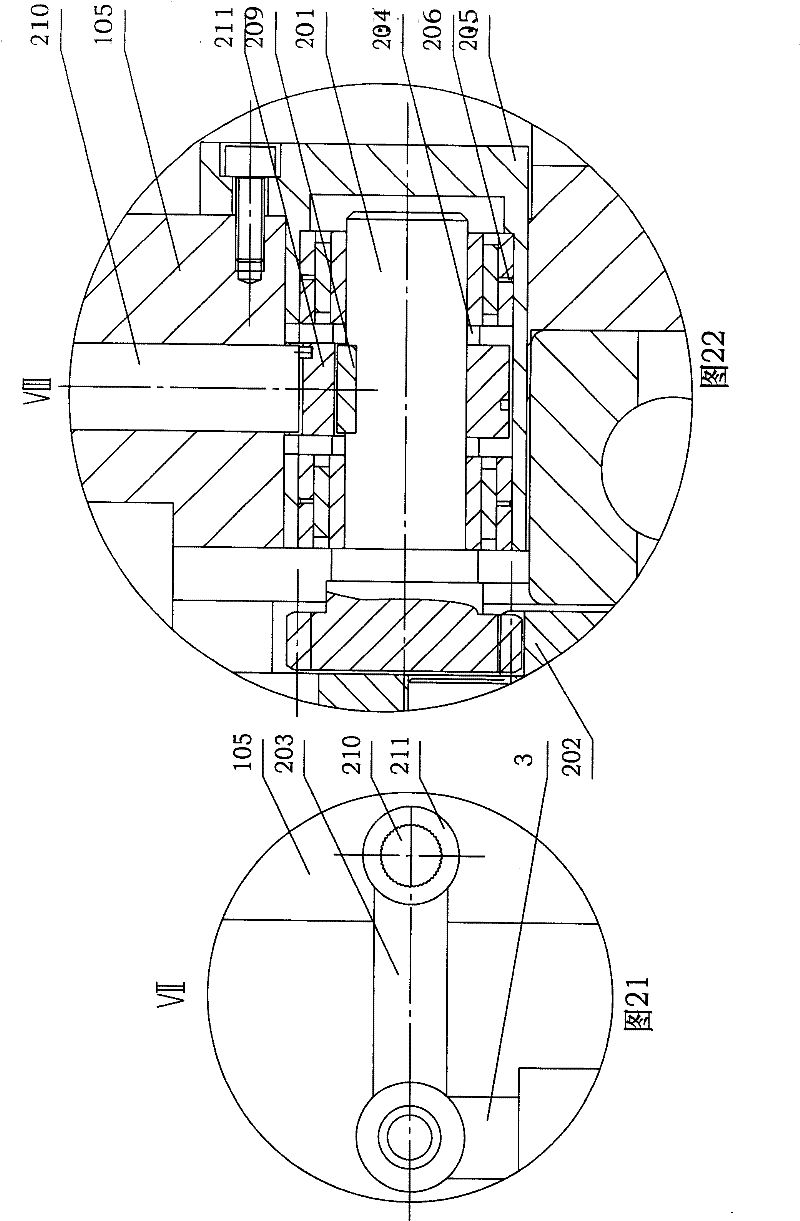

[0048] Referring to Fig. 21, shown in Fig. 22, described meshing element 2 also comprises parts and components such as camshaft 210, cam 211; Between two spacers 204 on its gear shaft 201, be connected with cam 211 by key 209, and cam 211 and The camshaft 210 cooperates, and one end of the camshaft 210 protrudes from the round hole on the circumference of the end cover 105, which can be the front end cover or the rear end cover, and is connected with the controller 3, and is sealed by a sealing ring; on one end of the gear shaft 201 The provided gear meshes with the rack 202 . All the other structures of embodiment 3 are the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com