Supporting-rod two-blade large-diameter changing reaming tool

A knife-wing and rod-type technology is applied to drilling equipment, drilling equipment and methods, and earthwork drilling and production. Large diameter range and good stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

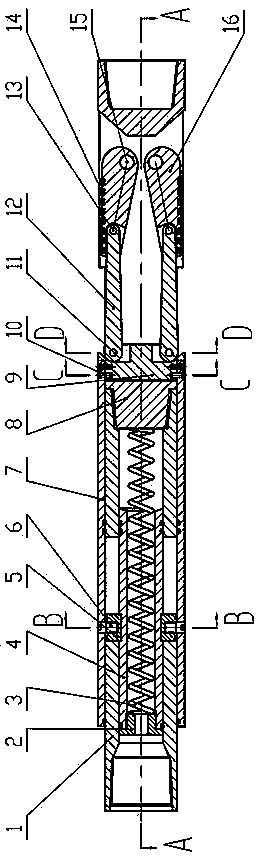

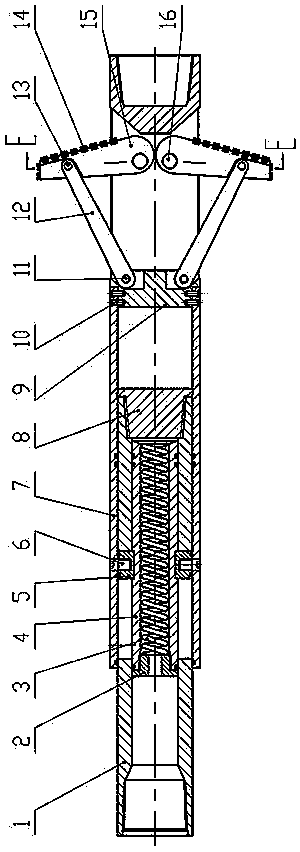

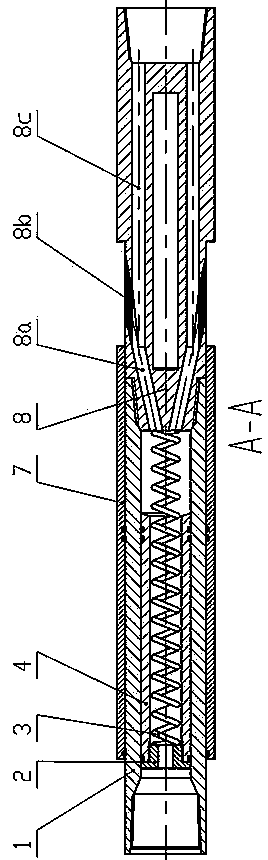

[0015] Such as figure 1 with figure 2 As shown, a strut-type two-blade large-diameter reaming tool of the present invention is composed of a main cylinder 1, a faucet 2, a return spring 3, an inner central tube 4, a slider 5, a screw a6, an outer central tube 7. Blade base 8, strut base 9, screw b10, pin a11, strut 12, pin b13, cutting teeth 14, blade 15, and bolt 16; The column thread is connected, and the lower end is connected with the knife wing seat 8 with a thread; the return spring 3 is placed in the inner cavity of the main cylinder 1 and installed on the upper end surface of the knife wing seat 8; the upper end of the inner central tube 4 is connected with the water nozzle 2 with a thread, and the inner The central tube 4 is placed in the inner cavity of the main cylinder 1, and the contact surface between the main cylinder 1 and the upper and lower ends of the inner central tube 4 is sealed with a sealing ring; the middle part of the inner central tube 4 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com