Low temperature aerosol deposition of a plasma resistive layer

A technology of air flotation deposition and air flotation, which is used in ion implantation plating, devices for coating liquids on surfaces, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

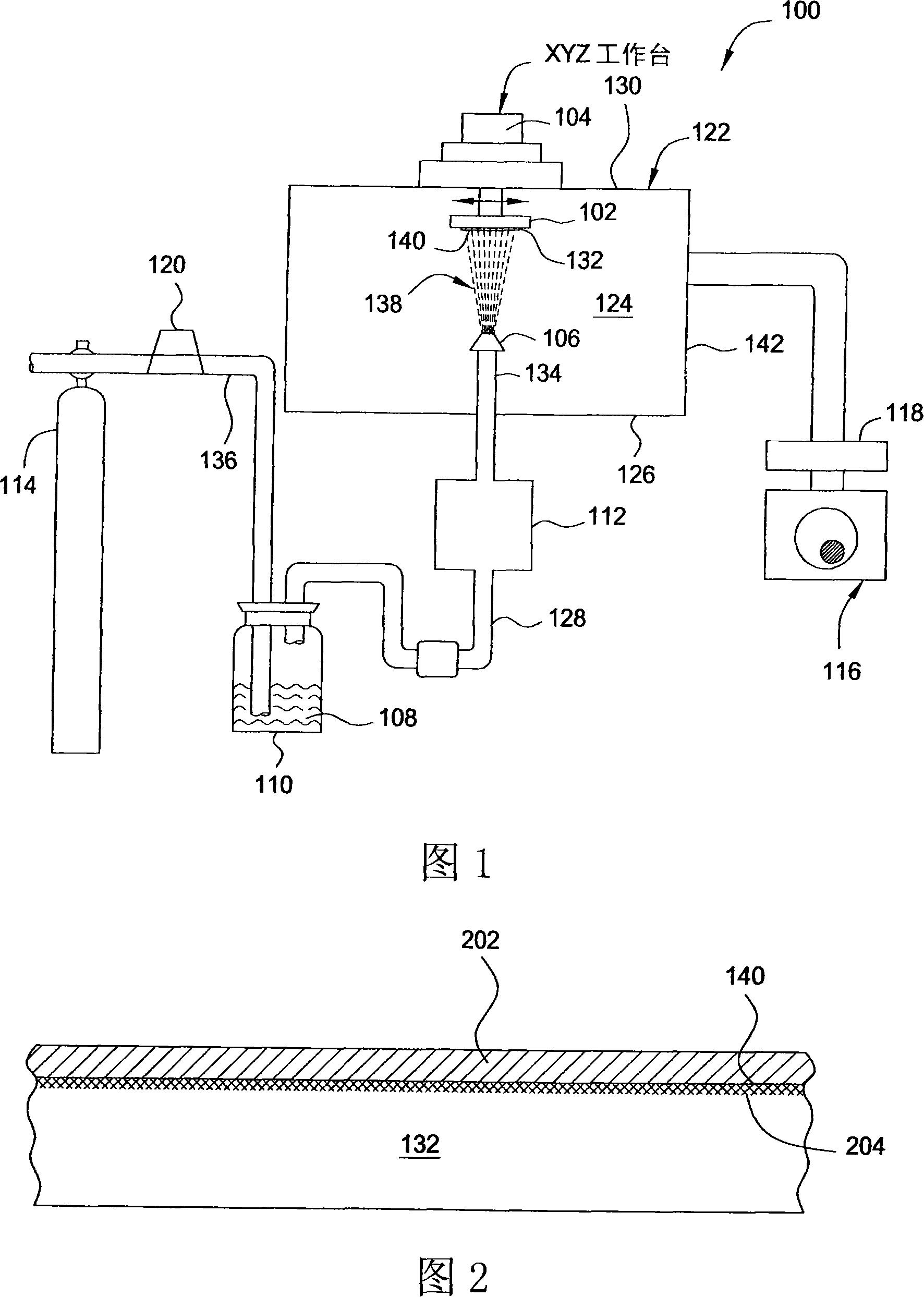

[0014] Figure 1 is a cross-sectional view of one embodiment of an apparatus 100 that may be used to perform an air-lift deposition (AD) process in accordance with the present invention. The air flotation deposition (AD) process of the present invention forms a plasma resistant layer that can be used to advantageously protect surfaces exposed to plasma treatment. Apparatus 100 includes a processing chamber 122 having a top 130 , a bottom 126 and side walls 142 defining a processing zone 124 within the interior of the processing chamber 122 . The workbench 104 is disposed on a ceiling 130 of the processing chamber 122 to a substrate holder 102 that holds a substrate 132 during processing. Table 104 is used to move fixture 102 along the X, Y and Z axes. Accordingly, the stage 104 moves the substrate 132 positioned thereon along the X, Y, and Z axes. Mechanical booster pump 116 and rotary pump 118 are coupled to processing region 124 through ports formed in sidewall 142 of proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com