Method for preparing nylon powder by employing DMF

A technology of nylon powder and nylon, which is applied in the field of preparing nylon powder by using DMF, which can solve the problems of not being able to prepare high-melting point nylon powder, and achieve the effects of narrow particle size distribution, convenient procurement, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

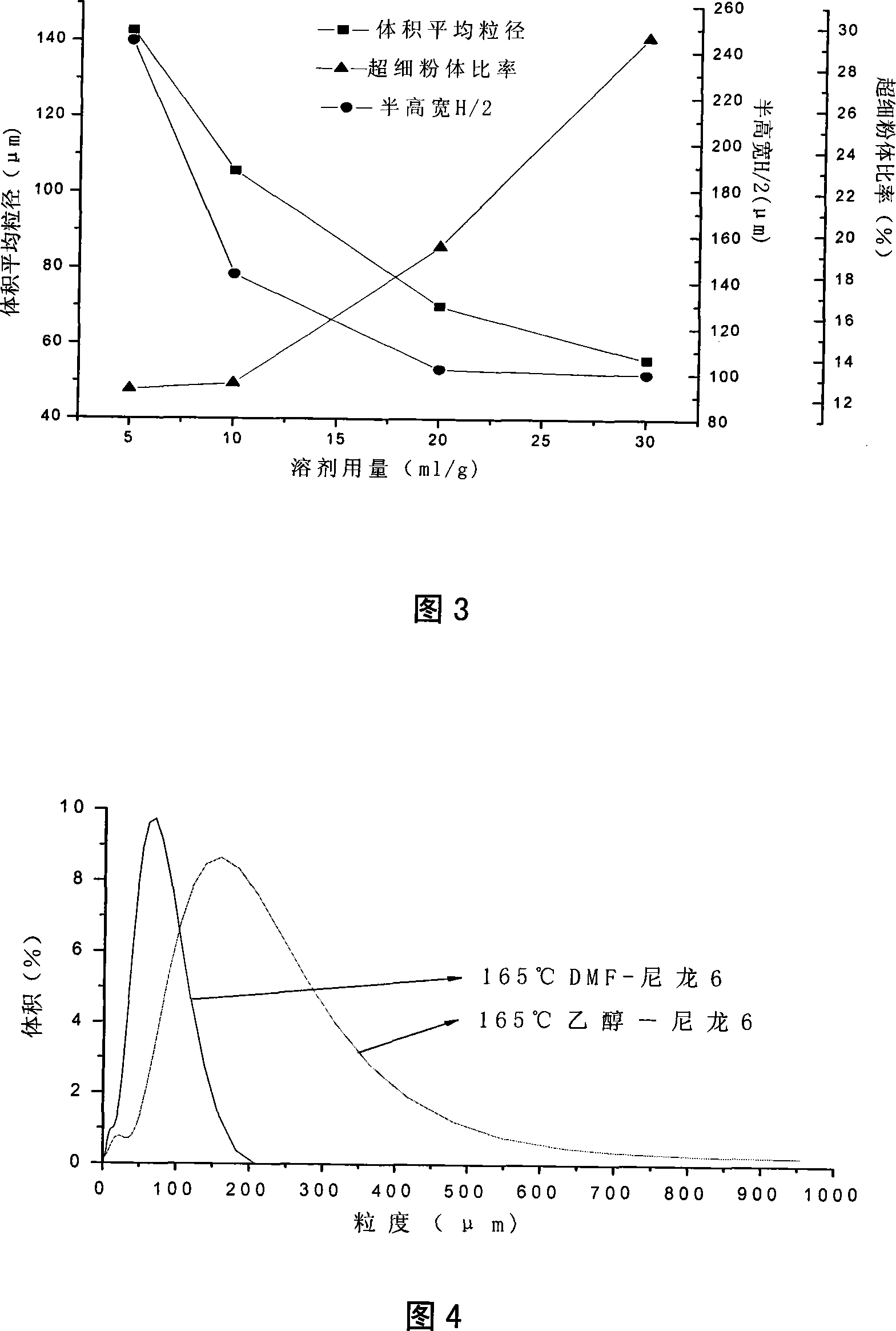

[0021] Be by weight ratio by nylon resin and DMF solvent: nylon resin: the ratio of DMF solvent=1: 3, add nylon 6 and DMF in the autoclave, stir while heating, be heated to 170 ℃, pressure is 1.0MPa, keep Press for 2 hours, stop heating, cool, discharge, dry under vacuum (-0.09MPa) temperature ≤ 90°C, recover solvent to prepare nylon 6 powder with volume average particle size of 90.2μm.

Embodiment 2

[0023] According to nylon resin and DMF solvent by weight ratio: nylon resin: the ratio of DMF solvent=1: 10, nylon 66 and DMF are added in the autoclave, stir while heating, be heated to 220 ℃, pressure is 1.1MPa, keep Press for 2.5 hours, stop heating, cool, discharge, and dry with hot air under normal pressure at a temperature of ≤70°C. Recover the solvent to obtain nylon 66 powder with a volume average particle size of 109.3 μm.

Embodiment 3

[0025] According to the weight ratio of nylon resin and DMF solvent: nylon resin: DMF solvent = 1: 20, add nylon 610 and DMF into the autoclave, stir while heating, heat to 220 ° C, and the pressure is 0.9 MPa at this time , keep the pressure for 1.8 hours, stop heating, cool, discharge, dry with hot air under normal pressure, and dry at a temperature ≤ 70°C, recover the solvent to prepare nylon 610 powder with a volume average particle size of 215.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com