Complex self-curing material, method and application of bioactivity calcium phosphate/tricalcium silicate

A tricalcium silicate, bioactive technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of poor bone-like apatite deposition ability, bonding strength and osteoconductivity strength. Poor, low strength and other problems, to achieve the effect of excellent biocompatibility, excellent biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Blending liquid preparation

[0052] Weigh 2.0 g of analytically pure sodium pyrophosphate and dissolve it in 98.0 mL of deionized water to obtain a 2.0% sodium pyrophosphate solution, sterilize, seal it in a sterile bottle, and set aside.

[0053] 2) Preparation of calcium phosphate / tricalcium silicate composite bone defect filling material:

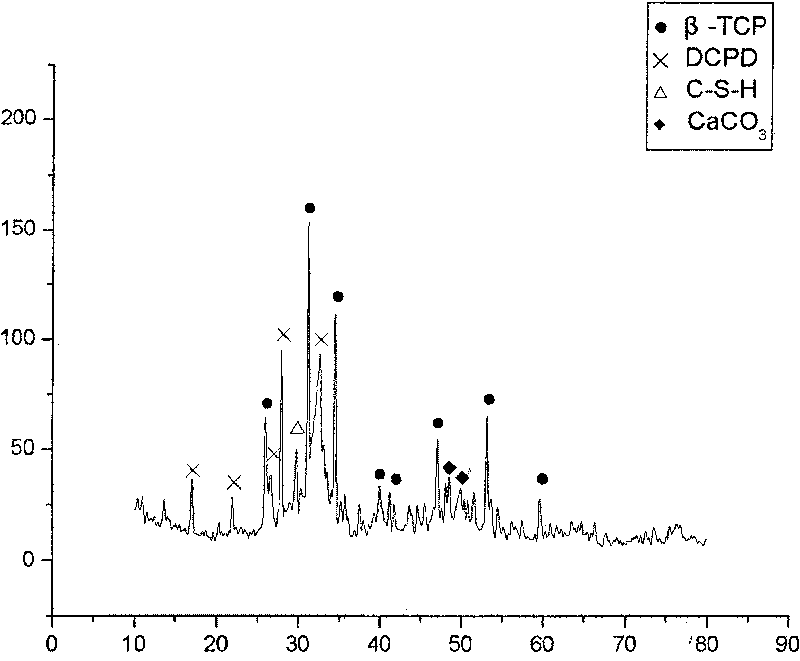

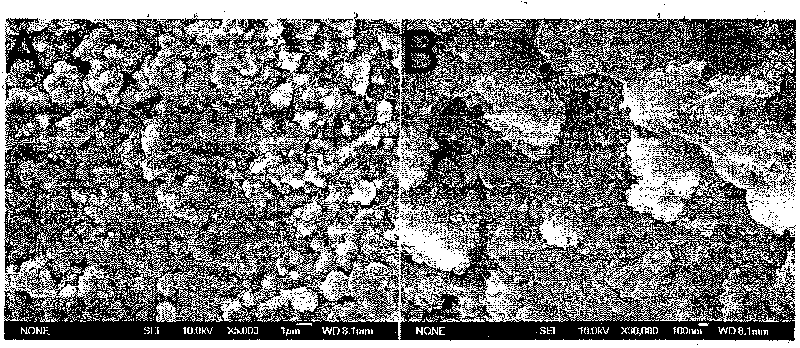

[0054] The calcium phosphate / tricalcium silicate composite material powder with a tricalcium silicate content of 20wt.% and the blending solution are fully blended at a liquid-solid mass ratio of 0.5:1 for 0.5-1 minute, injected into the mold, and heated at 37°C and After curing for more than 24 hours under 100% humidity, the calcium phosphate / tricalcium silicate composite pellets (CPC / C 3 S Pellets). The compressive strength of the pellets can reach 14.0∽19.0 MPa, the degradation rate can reach about 15% after 21 days, and it has good biological activity.

Embodiment 2

[0056] 1) Blending liquid preparation

[0057] Weigh 2.0 g of analytically pure sodium pyrophosphate and dissolve it in 98.0 mL of deionized water to obtain a 2.0% sodium pyrophosphate solution, sterilize, seal it in a sterile bottle, and set aside.

[0058] 2) Preparation of calcium phosphate / tricalcium silicate composite self-curing material:

[0059] The calcium phosphate / tricalcium silicate composite material powder with a tricalcium silicate content of 30wt.% and the blending solution are fully blended at a ratio of liquid-solid mass ratio of 0.5:1 for 0.5-1 minute, which can be used for minimally invasive treatment. Calcium phosphate / tricalcium silicate composite self-curing material. The self-curing material can be solidified in about 15 minutes after being injected into the defect, and the self-curing material slurry can be completely injected within 5 minutes. The compressive strength of the self-curing material can reach 36.0∽40.0MPa, and the degradation rate is abo...

Embodiment 3

[0061] Preparation of concoction

[0062] The simulated body fluid is used as the blending solution, and the ion concentration of the simulated body fluid is as follows (pH=7.25-7.4):

[0063] Table 2 Ionic composition of simulated body fluid

[0064] Ion species

Na +

K +

Mg 2+

Ca 2+

Cl -

HCO 3 -

HPO 4 2-

ion concentration

(mmol / L)

142.0

5.0

1.5

2.5

148.8

4.2

1.0

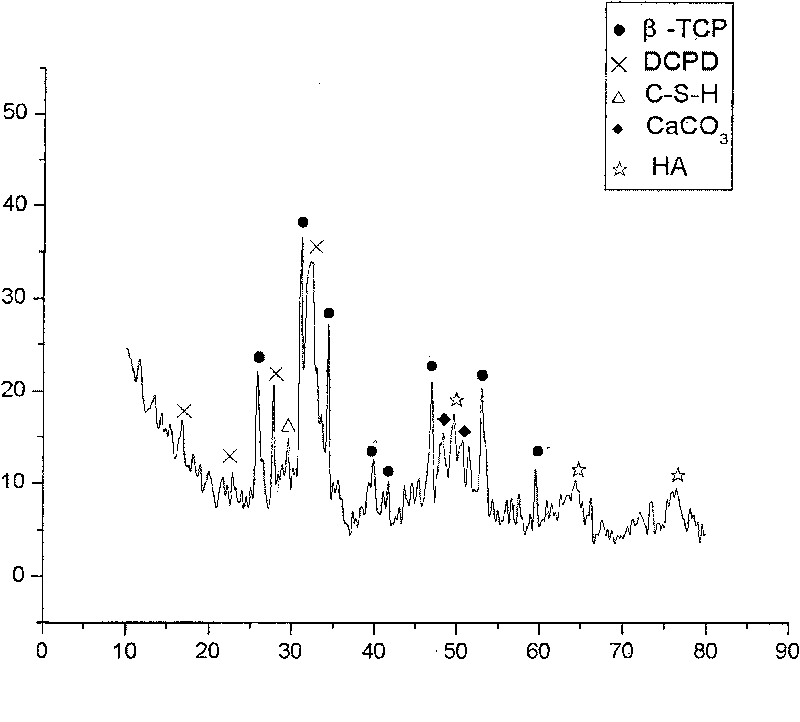

[0065] Preparation of calcium phosphate / tricalcium silicate composite degradable materials

[0066] The calcium phosphate / tricalcium silicate composite material powder with a tricalcium silicate content of 1-50wt.% and the blending solution are fully blended at a liquid-solid mass ratio of 0.5-1.0:1 for 0.5-1 minute, and injected into the mold. Cured at 37°C and 100% humidity for more than 24 hours, after which the calcium phosphate / tricalcium silicate composite pellets (CP / C)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com