Method for manufacturing unit doublet carbide codeposition fibre-reinforced composite

A composite material, fiber reinforced technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, to achieve the effect of excellent oxidation resistance, high high temperature strength and low internal stress

Inactive Publication Date: 2010-11-10

CENT SOUTH UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the international tendency is to coat refractory carbide (such as HfC, TaC) coatings on C / C composites as engine nozzles, and the coating performance of chemical vapor deposition is the best, but there are still great gaps. difficulty

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

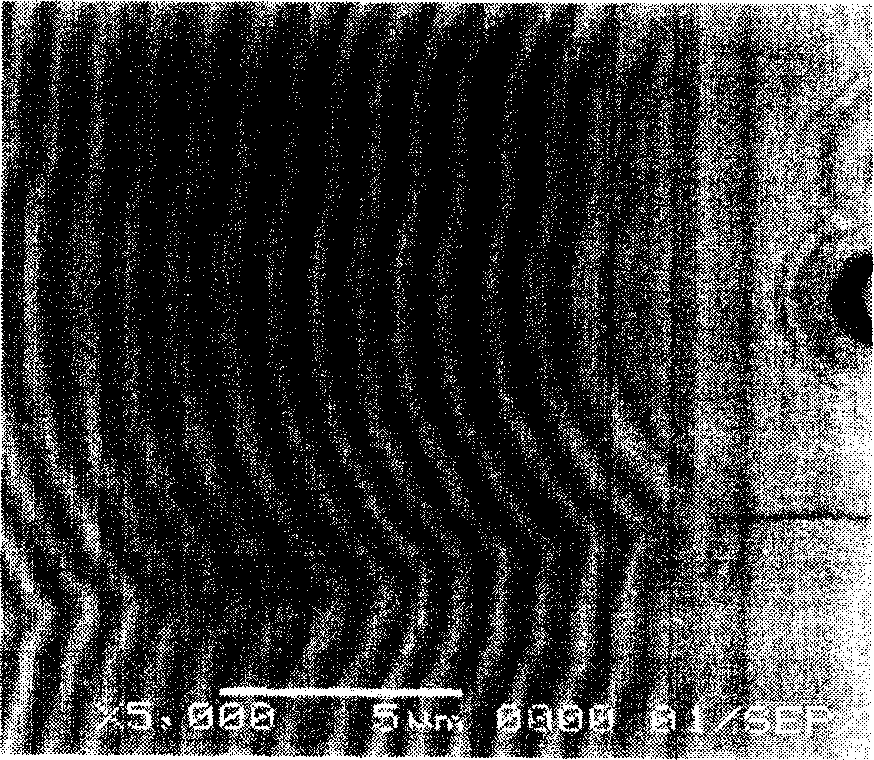

The invention relates to a preparation method for making unit doublet carbide codeposition fiber reinforcement composite material through chemical gas phase permeation / deposition process, wherein, codeposition unit doublet carbide is obtained inside a preformed billet body made of C fiber, boron fiber, ceramic fiber and metal fiber, etc. by use of the designability of chemical gas phase permeation / deposition process to make fiber-reinforcement unit doublet carbide composite material; the carbide is the combination of any two sorts of carbide of HfC, TaC, ZrC, NbC, WC, TiC, B4C, VC, AlC and SiC, etc. The material made through the method is characterized by high temperature resistance, wear resistance, anti scour, antioxidation, ablation resistance and excellent thermal shock resistance.

Description

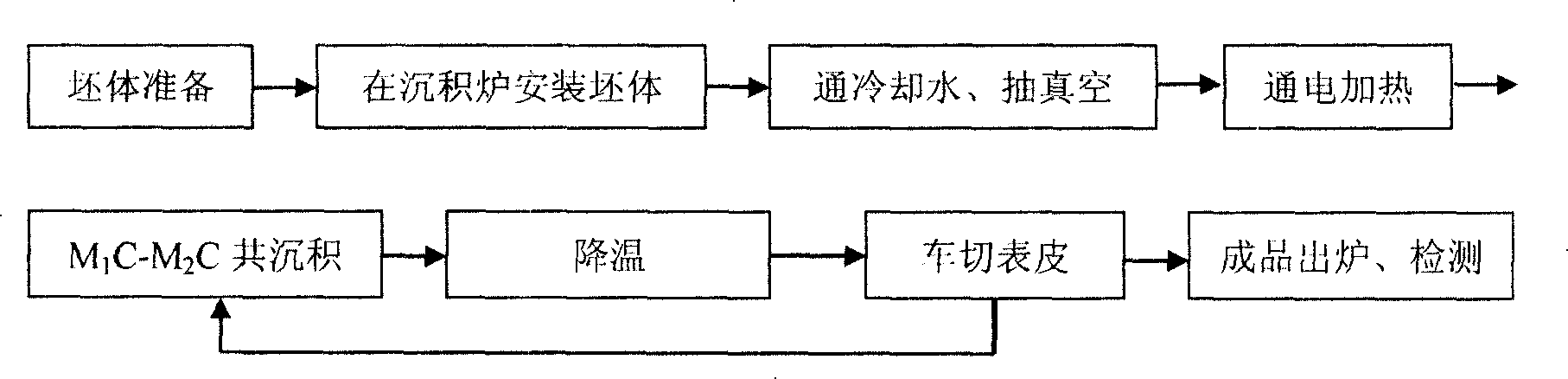

Manufacturing method of binary carbide co-deposition fiber reinforced composite material Technical field: Technical field: The present invention relates to a chemical vapor infiltration / deposition process for manufacturing binary carbide co-deposited fiber-reinforced composite materials, which are mainly used for functional structural components that require high temperature, high hardness, oxidation resistance, and ablation resistance. Background technique: Background technology: chemical vapor deposition chemically synthesizes materials at the atomic and molecular levels, so materials can be designed and prepared at the nanometer level; the preparation process can ensure the controllability and reproducibility of composition and structure; material preparation and device manufacturing have the same Sex; the equipment is relatively simple, easy to operate, and easy to realize automatic control. Another advantage of preparing materials by chemical vapor deposition is that ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C16/32C23C16/52C23C16/448

Inventor 李国栋熊翔陈昭科黄伯云张红波肖鹏

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com