Method for preparing nano titanium dioxide modified polyurethane material and products thereof

A nano-titanium dioxide, polyurethane material technology, applied in the field of material science, can solve the problems of inability to inhibit the self-aggregation of nanoparticles, difficult to disperse and uniform dispersion of nano-powders, difficult to ensure the effectiveness of nano-powders, etc., and achieve strong self-cleaning performance. , The effect of high compression recovery rate and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

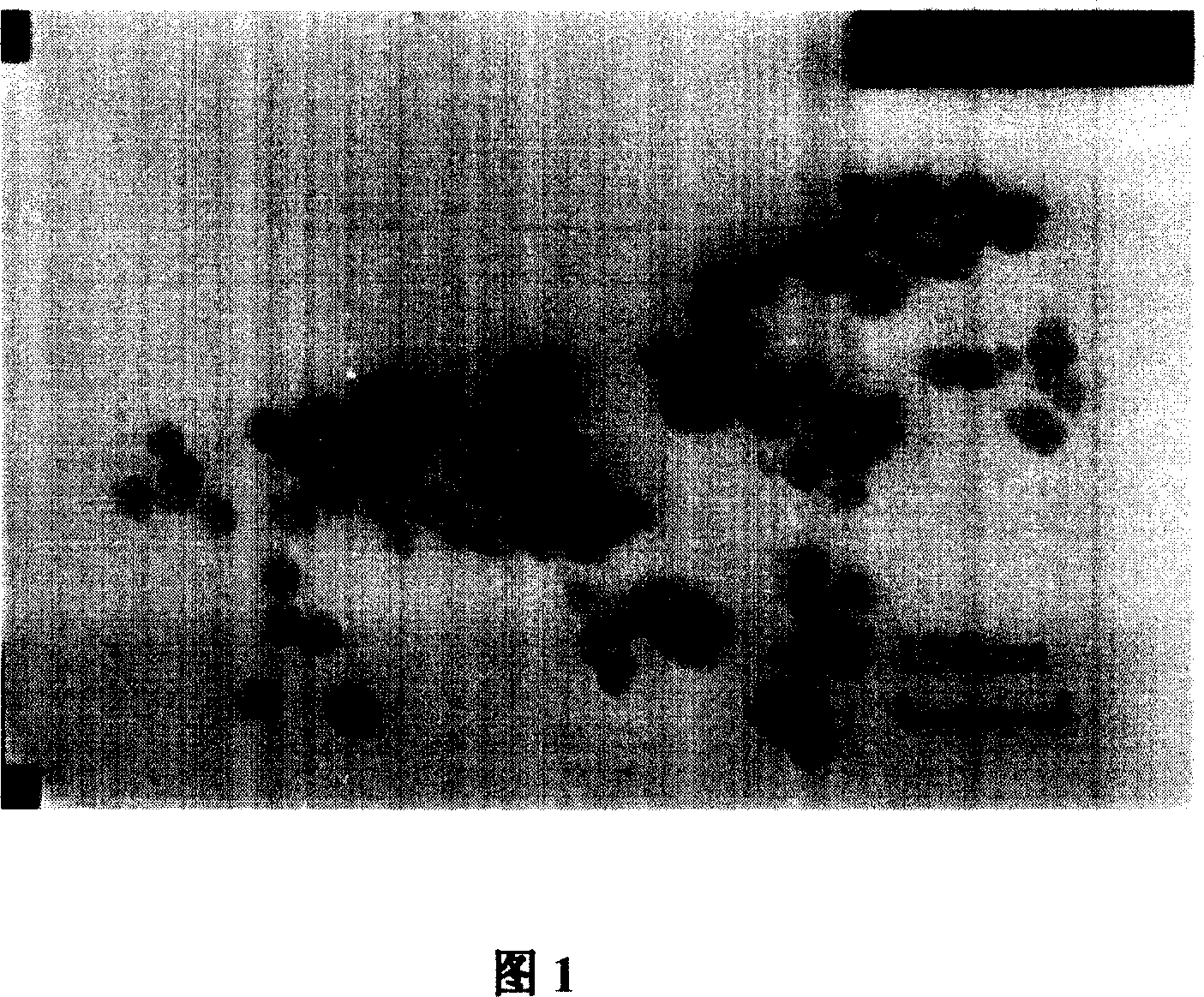

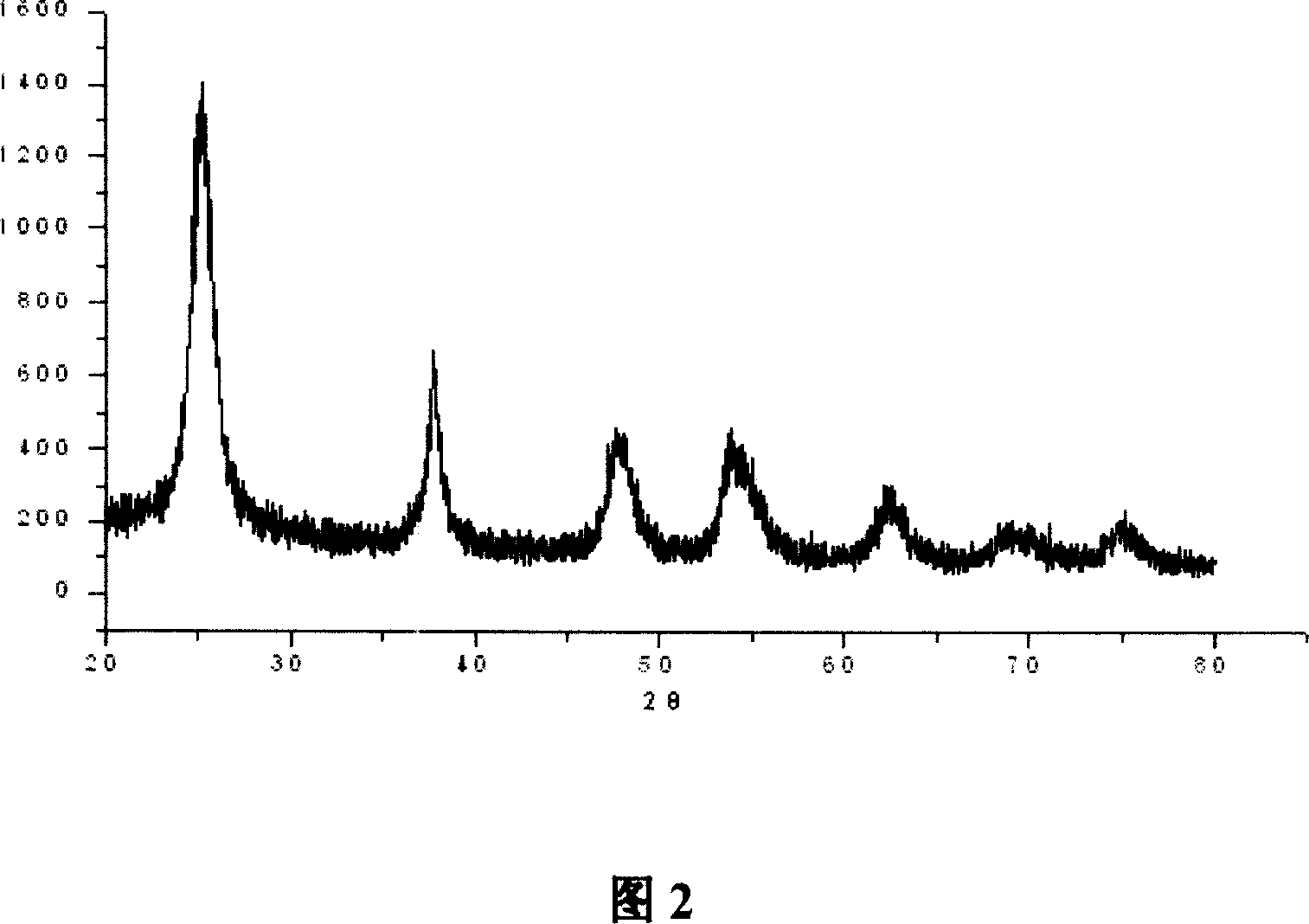

Image

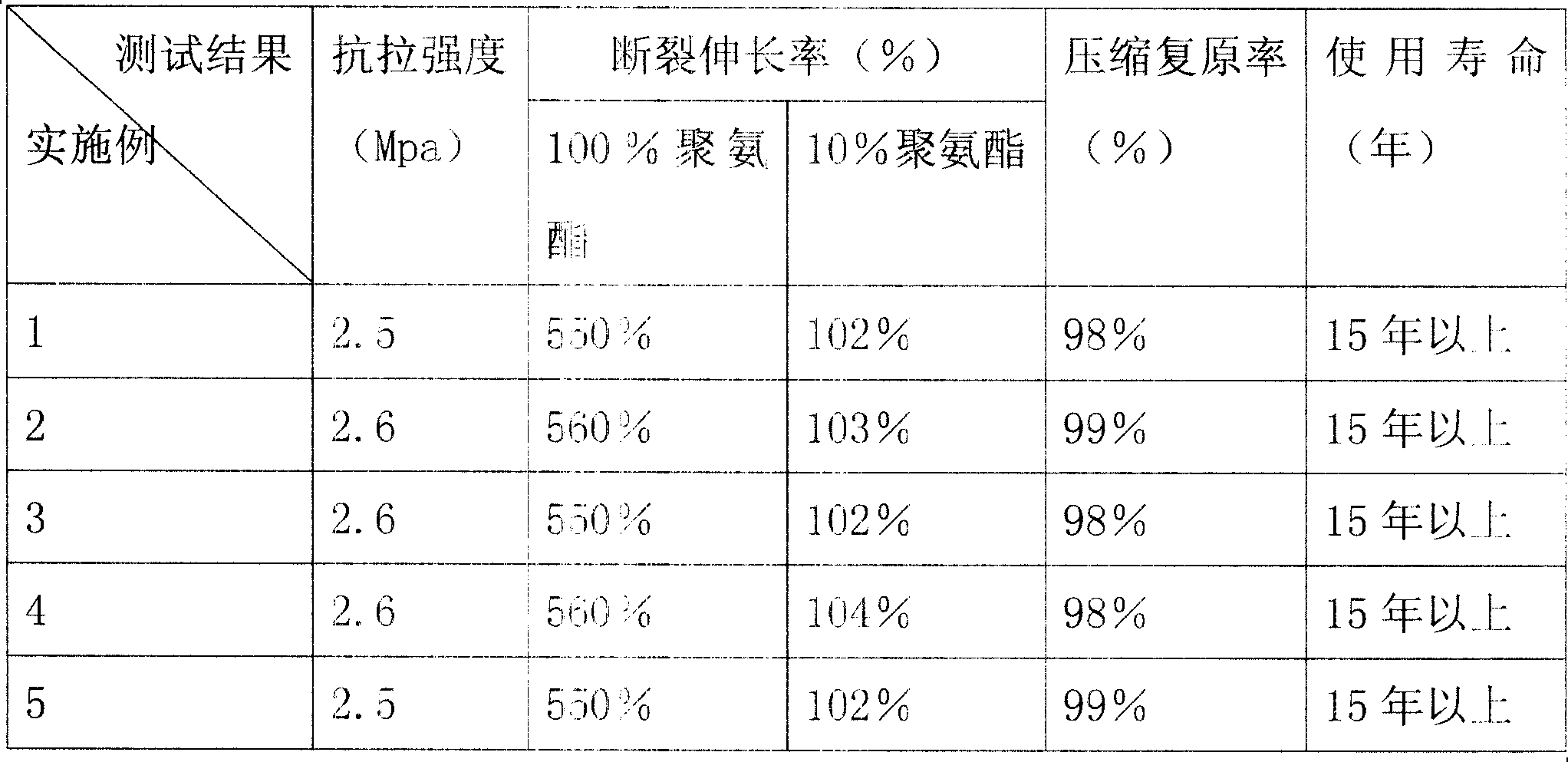

Examples

Embodiment 1

[0025] 1. Preparation of nano-titanium dioxide precursor solution: adding titanium tetrachloride solution to benzoic acid solution, stirring evenly to obtain nano-titanium dioxide precursor solution; wherein the volume ratio of titanium tetrachloride solution and benzoic acid solution is 1:5;

[0026] 2. Preparation of component B of the polyurethane material: uniformly mix the conventional components for preparing the polyurethane material, add 1% by weight nano-titanium dioxide precursor solution to the above components, and react under the condition of stirring and mixing, and the product is obtained after the reaction Polyurethane material component B; wherein the reaction temperature is 60°C, and the stirring and mixing time is 20 hours;

[0027] 3. Preparation of nano-titanium dioxide-modified polyurethane material: After uniformly mixing the above-mentioned polyurethane material component B and polyurethane material component A, at a temperature of 20°C, cross-linking an...

Embodiment 2

[0029] 1. Preparation of nano-titanium dioxide precursor solution: adding titanium tetrachloride solution to benzoic acid solution, stirring evenly to obtain nano-titanium dioxide precursor solution; wherein the volume ratio of titanium tetrachloride solution and benzoic acid solution is 1:10;

[0030] 2. Preparation of component B of polyurethane material: uniformly mix the conventional components for preparing polyurethane material, add 10% by weight nano-titanium dioxide precursor solution to the above components, and react under the condition of stirring and mixing. After the reaction, it is obtained Polyurethane material component B; wherein the reaction temperature is 90°C, and the stirring and mixing time is 15 hours;

[0031] 3. Preparation of nano-titanium dioxide-modified polyurethane material: After uniformly mixing the above-mentioned polyurethane material component B and polyurethane material component A, at a temperature of 50°C, cross-linking and curing within 4 ...

Embodiment 3

[0033] 1. Preparation of nano-titanium dioxide precursor solution: adding titanium tetrachloride solution to benzoic acid solution, stirring evenly to obtain nano-titanium dioxide precursor solution; wherein the volume ratio of titanium tetrachloride solution and benzoic acid solution is 1:20;

[0034] 2. Preparation of component B of the polyurethane material: uniformly mix the conventional components for preparing the polyurethane material, add 15% by weight nano-titanium dioxide precursor solution to the above components, and react under the condition of stirring and mixing, and the product is obtained after the reaction Component B of polyurethane material; the reaction temperature is 100°C, and the mixing time is 3 hours;

[0035]3. Preparation of nano-titanium dioxide-modified polyurethane material: After uniformly mixing the above-mentioned polyurethane material component B and polyurethane material component A, at a temperature of 80°C, cross-linking and curing within 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com