Film-transferring printing method

A printing method and a film transfer technology, which are applied in printing, printing process, ink transfer from original manuscript, etc., can solve the problem that the effective transfer of printing ink layer and aluminum spray layer cannot be satisfied, the peeling effect of the layer is greatly affected, and the color of the printed matter cannot be solved. Solve problems such as low saturation, achieve effective peeling and transfer, bright and elegant printed products, and strong metal texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

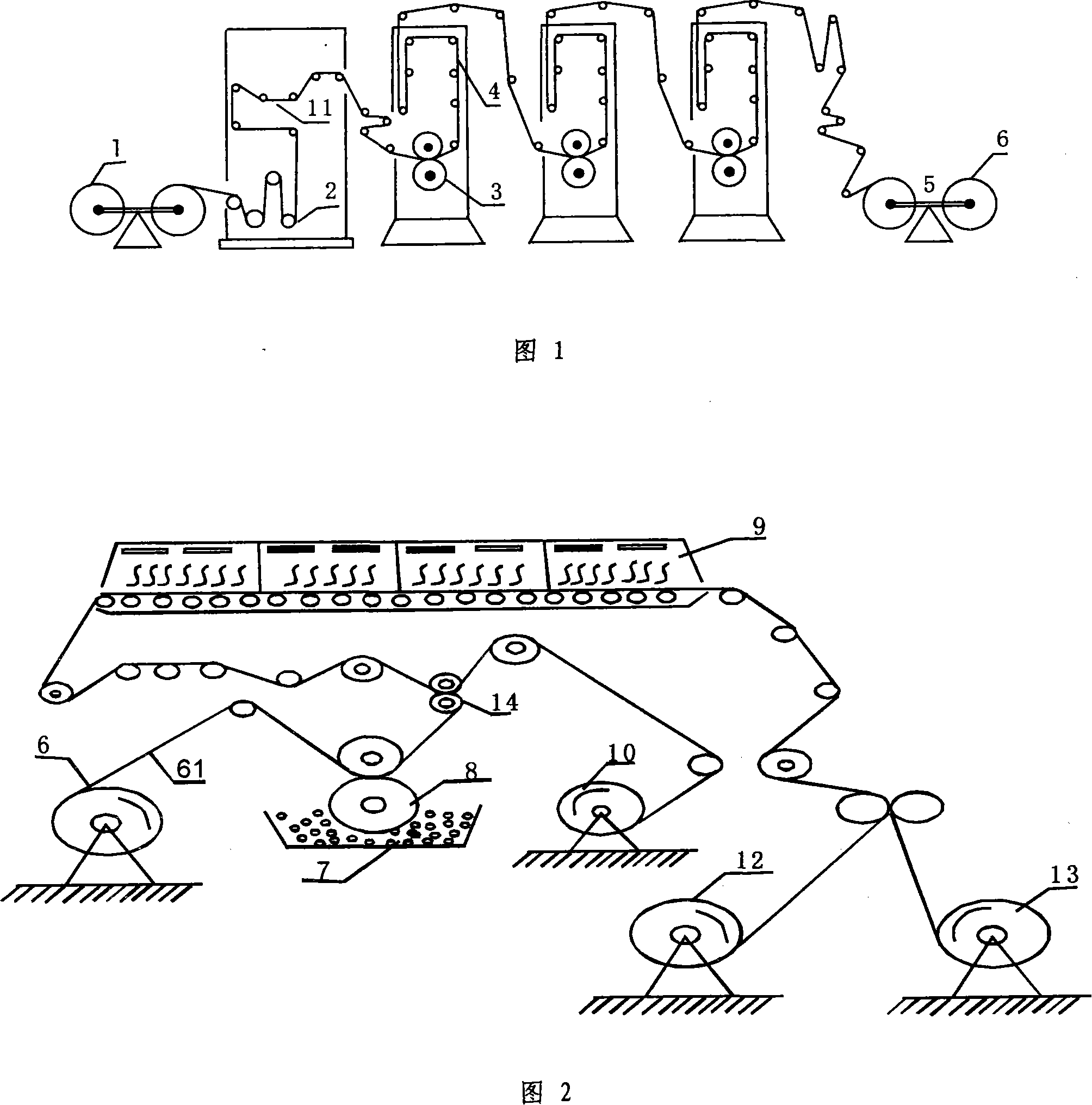

[0032] Embodiment one, the film transfer printing technological process of common effect:

[0033] This embodiment selects PET film as the base film, and the thickness is controlled between 20-35um. Among polyester films, the stretchability of PET film is relatively stable, which is conducive to tension control during printing, molding and transfer, and reduces the tension of the film. The effect of stretch deformation on printed graphics. First, one side of the film is coated with a layer of release material by a coating machine (in-line coating can also be performed by using a gravure printing unit). The main components of the release layer material are silicon dioxide and methylhydrazone acetaldehyde, the pH value is 7-8, the solid content is 45±2%, and the viscosity in the Tu 4# cup is 25-40 seconds. As shown in Figure 1, the PET film 1 coated with the release layer is installed on the gravure printing machine, wherein 11 is the coating surface, and the pattern is copied ...

Embodiment 2

[0035] Embodiment 2, process flow of film transfer printing with photosilver effect:

[0036] In this embodiment, PET film is selected as the base film, and the PET film is controlled between 20-35um. First, one side of the film is coated with a layer of release material by a coating machine (in-line coating can also be performed by using a gravure printing unit). The main components of the release layer material are silicon dioxide and methylhydrazone acetaldehyde, the pH value is 7-8, the solid content is 45±2%, and the viscosity in the Tu 4# cup is 25-40 seconds. Then as shown in Figure 1, the PET film 1 coated with the release layer is installed on the gravure printing machine, wherein 11 is the coating surface, and the pattern is reproduced on the film through multiple groups of gravure printing units 3 and drying units 4 and then Drying is achieved, and finally the winding device 5 performs winding to make a transfer film 6 with complete graphic information. As shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com