Flux powder for brazing aluminum material and process for producing the flux powder

A flux and powder technology, applied in welding/cutting media/materials, welding equipment, manufacturing tools, etc., can solve the problems of inability to remove material oxide film, inability to expand, inability to show sufficient performance, etc., to achieve improvement Remove the effects of increased capacity, cheap economics, mobility and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] Hereinafter, examples and comparative examples of the present invention will be described in detail together.

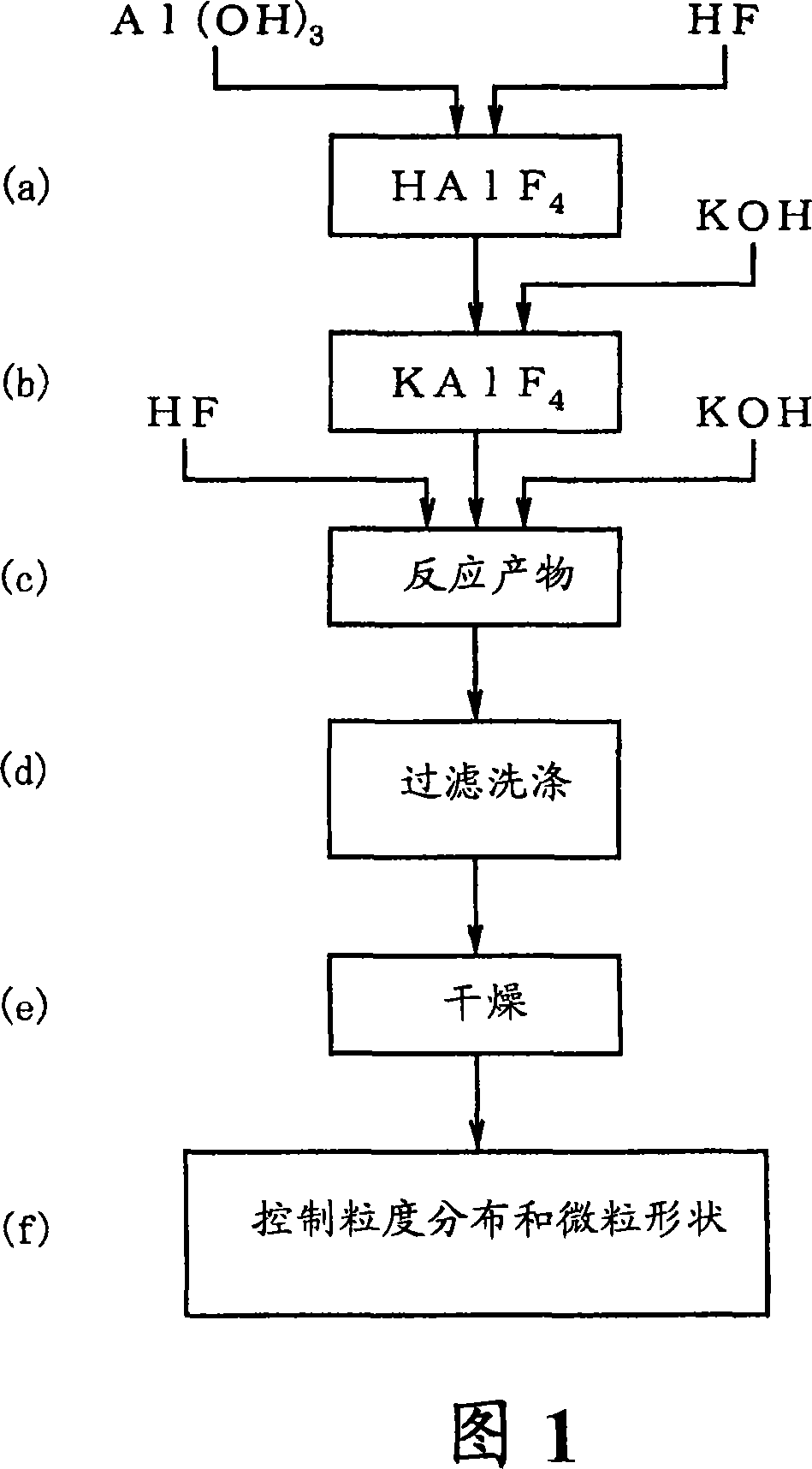

[0063]

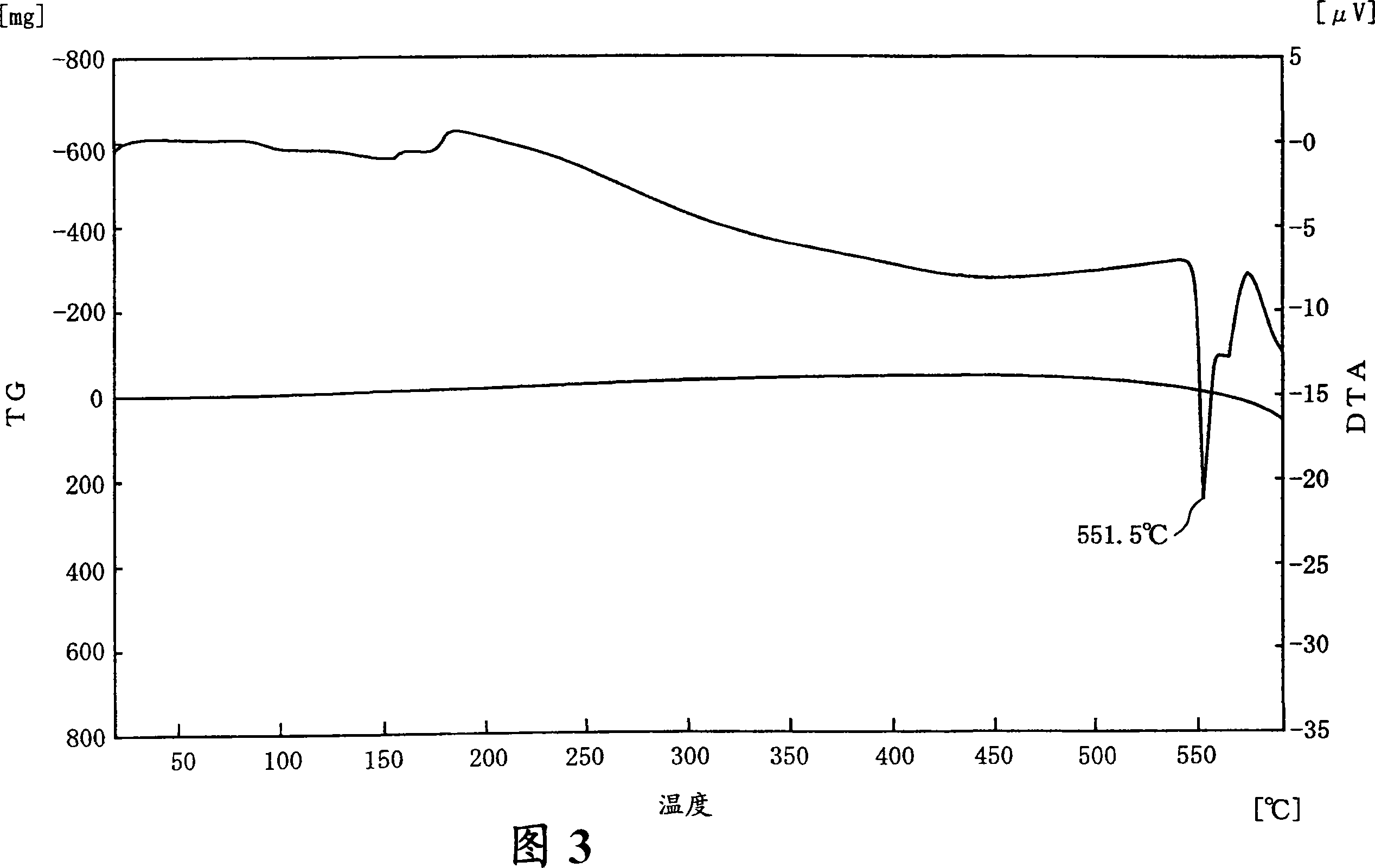

[0064]First, aluminum hydroxide, hydrofluoric acid and potassium hydroxide are used as raw material compounds, and the raw material compounds are used according to the filler K / Al molar ratio and the filler F / Al molar ratio shown in Table 1 and Table 2 below, and make it in the following The wet reaction was carried out at the reaction temperatures shown in Tables 1 and 2 to prepare flux powder samples No.1 to No.32 having the composition ratios shown in Tables 1 and 2 below, respectively. Among the flux powder samples prepared, samples No.12 to No.24 correspond to flux powders of the present invention, and samples No.1 to No.11 and samples No.25 to No.32 are outside the scope of the present invention flux powder. Calculate the K of the prepared flux powder samples after heating at 500°C for 15 minutes 2 AlF 5 ·H 2 Weight loss due to desorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com