Lighting device for vehicle and method of manufacturing the same

A manufacturing method and technology for lamps, which are applied in the direction of headlights, road vehicles, household appliances, etc., can solve the problems of low cost, reduced specular reflectivity, difficulty in improving the appearance effect and high-end feeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

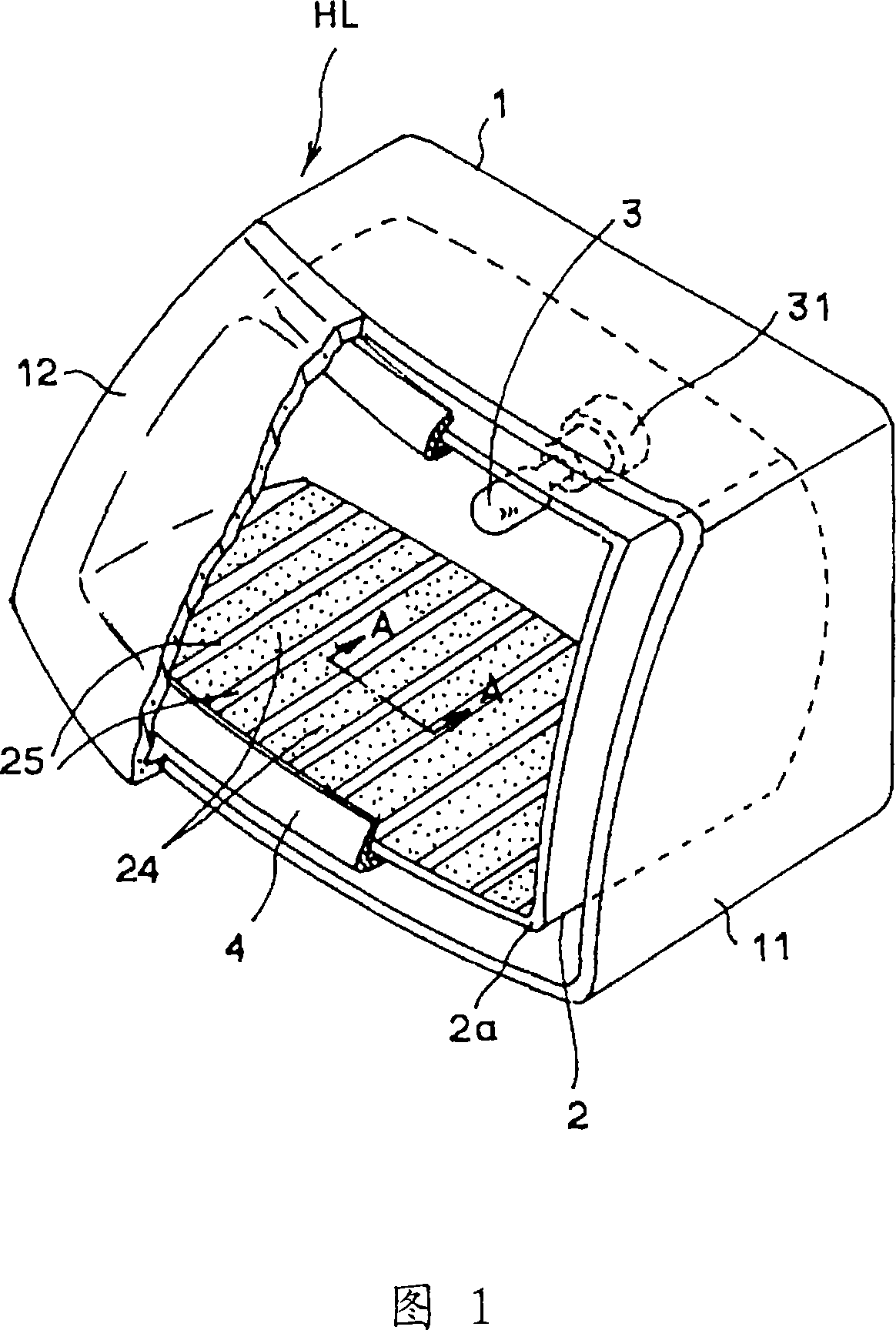

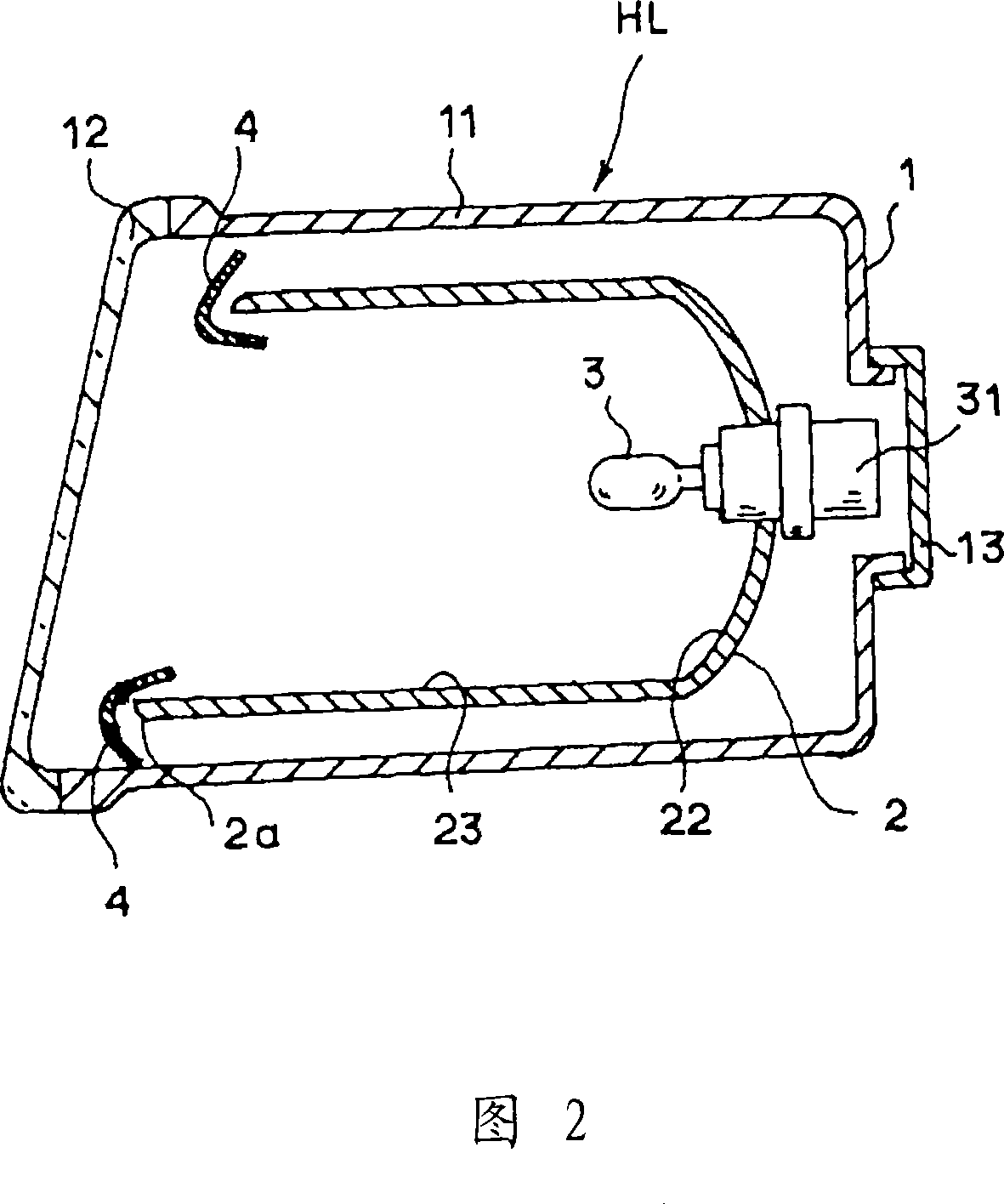

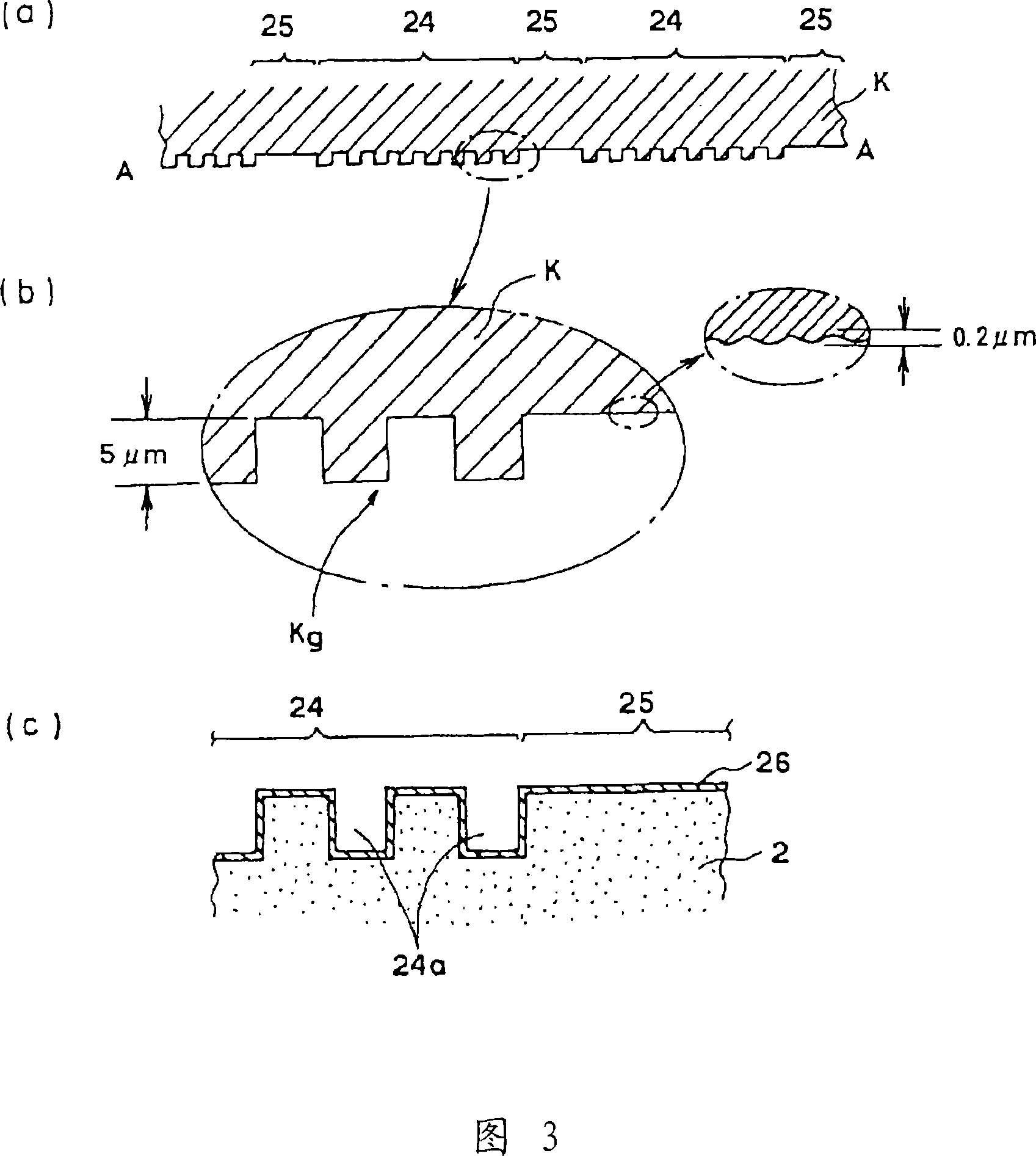

[0023] Next, a first embodiment of the present invention will be described with reference to the drawings. FIG. 1 is a partially cut away perspective view of a first embodiment of a headlamp HL in which the present invention is applied to an automobile, and FIG. 2 is a longitudinal sectional view thereof. In these figures, a lamp body 11 having a substantially rectangular front shape, a front lens 12 made of transparent resin attached to the front opening of the lamp body 11, and a rear cover 13 covering the rear opening of the lamp body 11 are formed. A lamp housing 1 is formed, and a reflector 2 is built in the lamp housing 1 . An opening of a bulb mounting hole 21 is formed on the back surface of the reflector 2, and an incandescent lamp or a discharge bulb 3 as a light source is mounted by a socket 31. As shown in FIG. The reflector 2 can be tilted up and down, left and right by an adjustment mechanism not shown in the figure, thereby, the position of the central optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com