Roller armrest stepless adjustment mechanism and car seat armrest

A stepless adjustment, roller-type technology, applied in vehicle seats, armrests, vehicle parts, etc., can solve the problem that the armrest cannot meet the needs of users of different sizes, only two positions of the initial point and the end use point, the armrest Unable to use height and other issues, to achieve the effect of high-level sense, broad market application prospects, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

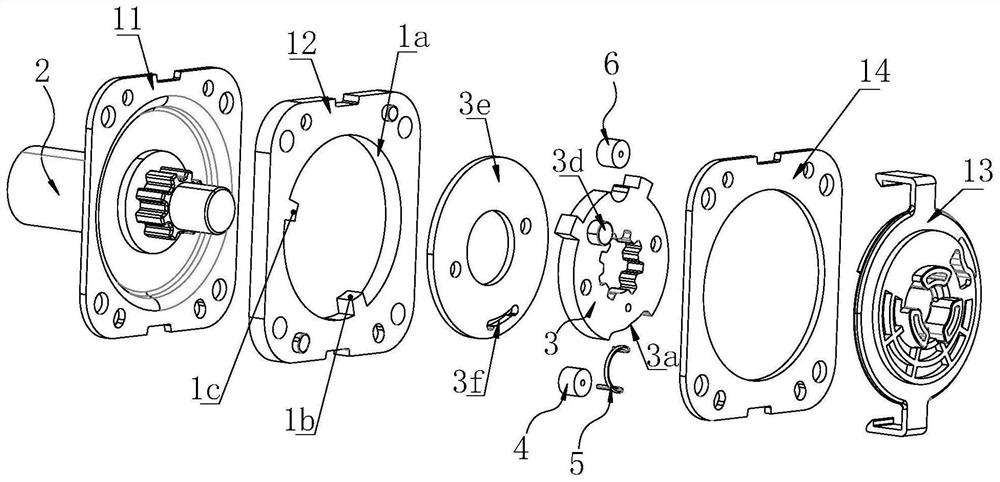

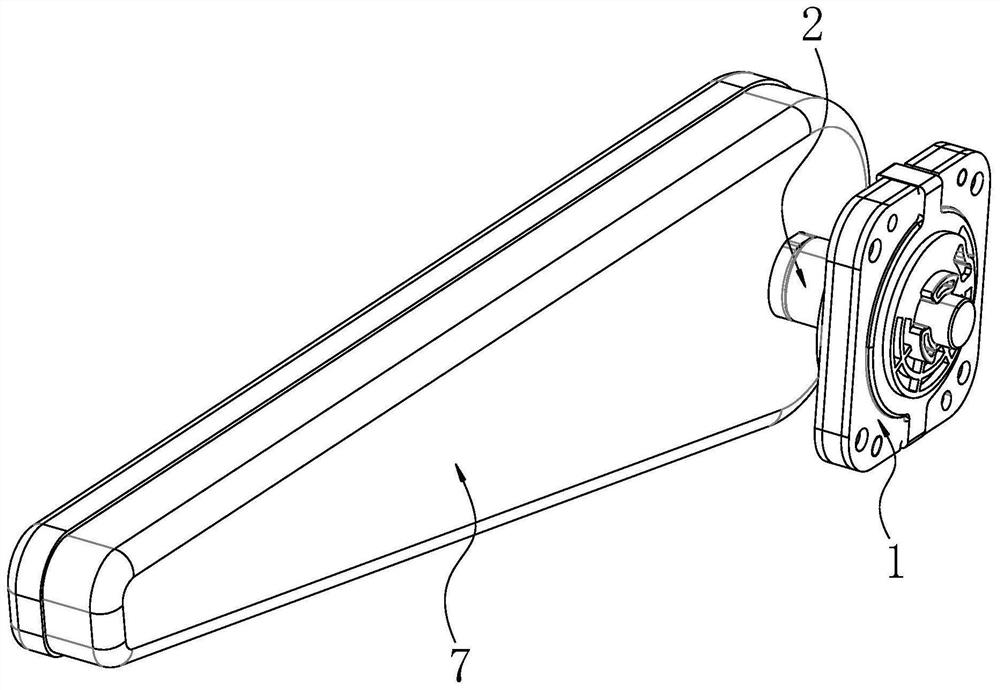

[0029] Such as figure 1 and 2 As shown, a roller type armrest stepless adjustment mechanism, the components involved in the adjustment mechanism are: housing assembly 1, rotating shaft 2, drive plate 3, roller 4, elastic element 5, balance roller 6, wherein the housing The assembly 1 is formed by buckling the end shell 11, the middle plate 12 and the end cover plate 13. The middle plate 12 is a hollow structure and is located between the end shell 11 and the end cover plate 13. The end shell After the body 11, the middle plate 12 and the end cover plate 13 are buckled together, the middle plate 12 of the hollow structure forms an assembly cavity 1a inside the shell assembly 1, and the rotating shaft 2 is rotatably installed on the shell assembly 1 and passed through Through the assembly cavity 1a, the inner wall of the assembly cavity 1a is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com