Method for directly producing ferrochromium from chrome ore powder and coal

A ferrochrome alloy and production method technology, which is applied in the field of direct production of ferrochrome alloy by using chrome ore powder and coal, can solve the problems of large consumption of ferrosilicon reduction, large consumption of argon gas, and short service life of furnace lining, so as to reduce dependence and improve Effects of reduction rate of metal and acceleration of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

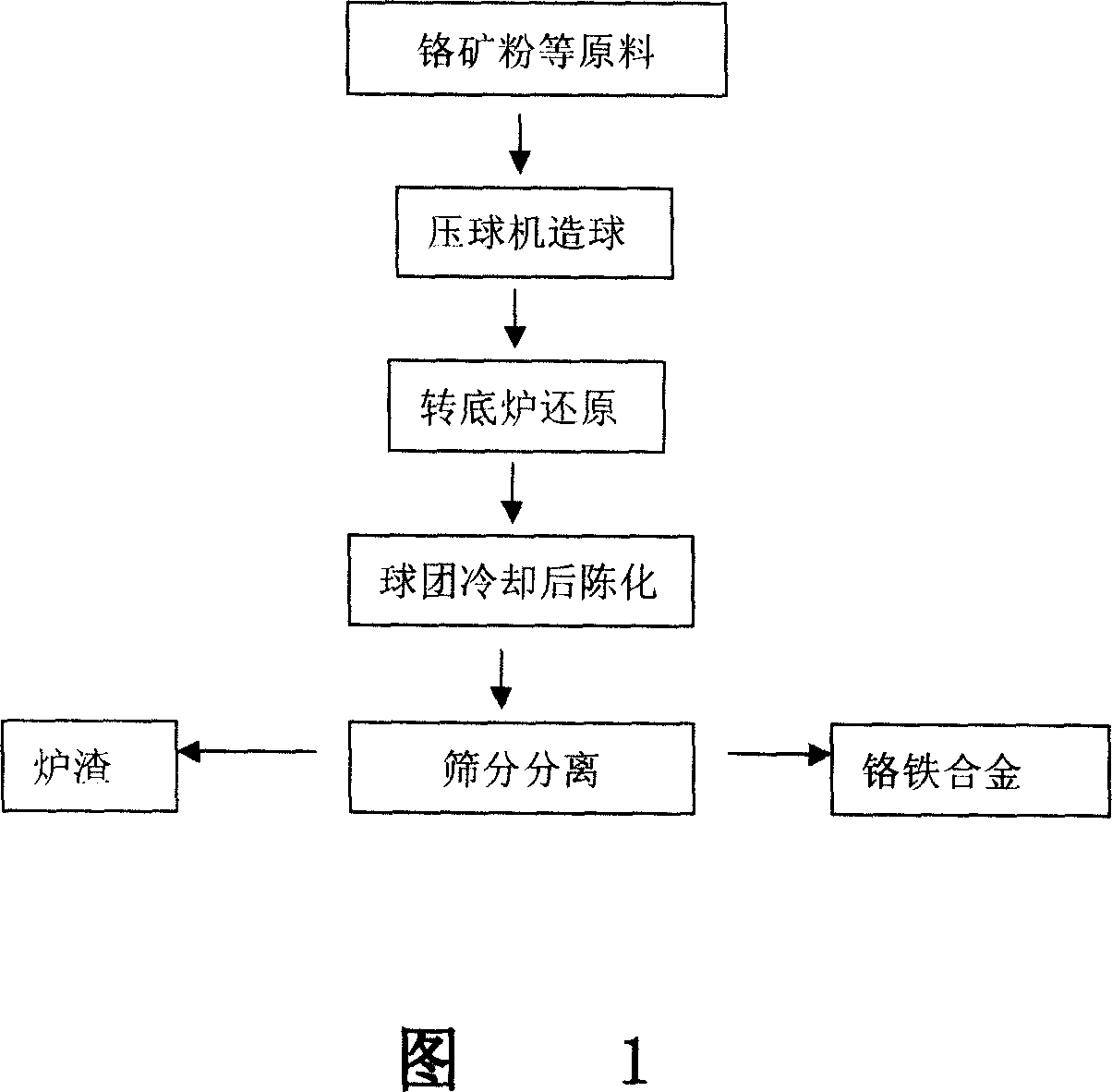

Method used

Image

Examples

Embodiment 1

[0074] (1) Ingredients

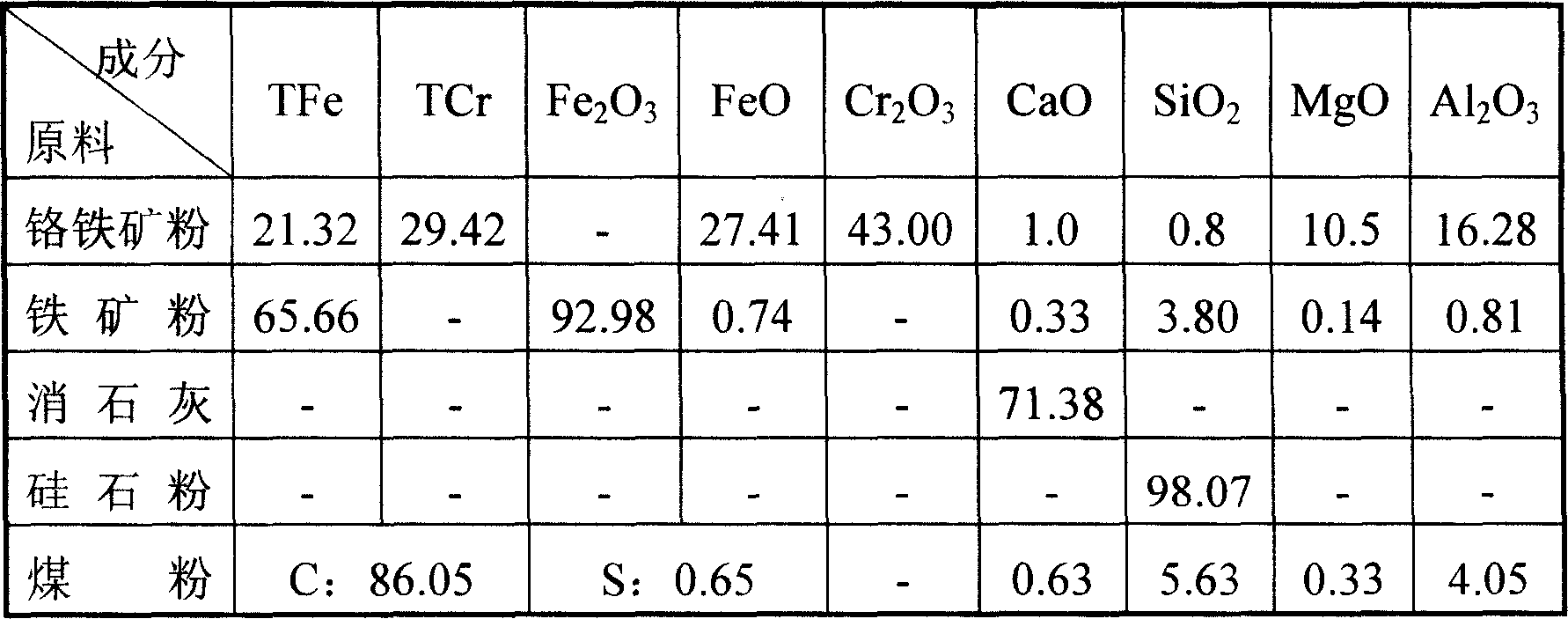

[0075] According to the chemical composition range of each component in the pellets and the principle of ingredients, three batches of pellet reduction tests were carried out. Table 1 is the main chemical composition of each raw material.

[0076] Table 1 The main chemical composition of each raw material (%)

[0077]

[0078] (2) Mixing

[0079] Using the raw materials in Table 1, according to the principle of the present invention, take Cr / (Fe+Cr)=30% in the pellets, and Al in the slag phase 2 O 3 = 15%, alkalinity R = 1.6, fully mix and make it uniform in the mixer, spray 7-10% of water in the late stage of mixing to fully wet it.

[0080] (3) Pellet suppression

[0081] The above-mentioned mixed raw materials are pressed in a ball press into oblate pellets with a length of about 3 cm and a width of about 3 cm and a thickness of about 2 cm (or slightly larger or smaller). The composition is shown in Table 2.

[0082] Table 2 Ingredients composition of...

Embodiment 2

[0092] Except for the following steps, the others were the same as in Example 1, and the ferrochrome alloy was prepared.

[0093] (3) Pellet suppression

[0094] The mixed raw materials obtained in the step (2) of Example 1 are pressed in a ball press into oblate pellets with a length of about 3 cm and a width of about 3 cm and a thickness of about 2 cm (or slightly larger or smaller). See Table 4.

[0095] Table 4 Ingredients composition of pellets (%)

[0096] Raw materials

[0097] (4) Pellet aging

[0098] The above pellets were reduced in a rotary hearth furnace, the temperature was controlled at 1450°C, and the reduction time was 20 minutes. The pellets after being baked are cooled and aged. The pellets are pulverized after aging for one day.

[0099] (5) Screening and separation

[0100] The above-mentioned pellets were pulverized and sieved to obtain ferrochromium alloy. The composition and yield of chromium and iron are shown in Table 5.

[0101] Table 5 Compositi...

Embodiment 3

[0105] Except for the following steps, the others were the same as in Example 1, and the ferrochrome alloy was prepared.

[0106] (3) Pellet suppression

[0107] The raw materials mixed in the step (2) of Example 1 are pressed in a ball press into oblate pellets with a length of about 3 cm and a width of about 3 cm and a thickness of about 2 cm (or slightly larger or smaller). The composition is shown in the table 6.

[0108] Table 6 Ingredients composition of pellets (%)

[0109] Raw materials

[0110] (4) Pellet aging

[0111] The above three kinds of pellets were reduced in a rotary hearth furnace, the temperature was controlled at 1450°C, and the reduction time was 20 minutes. The pellets after being baked are cooled and aged. The pellets are pulverized after aging for one day.

[0112] (5) Screening and separation

[0113] The above-mentioned pellets were pulverized and sieved to obtain ferrochromium alloy. The composition and yield of chromium and iron are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com