Microwave excitation auto-igniting synthesizing method for porous titanium nickel alloy

A synthesis method and self-propagating combustion technology, which is applied in the field of microwave chemical self-propagating combustion synthesis, can solve the problems of high brittleness of titanium-nickel alloys and shorten the residence time, and achieve the advantages of reducing high-temperature oxidation burning loss, simplifying synthesis equipment, and short heating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

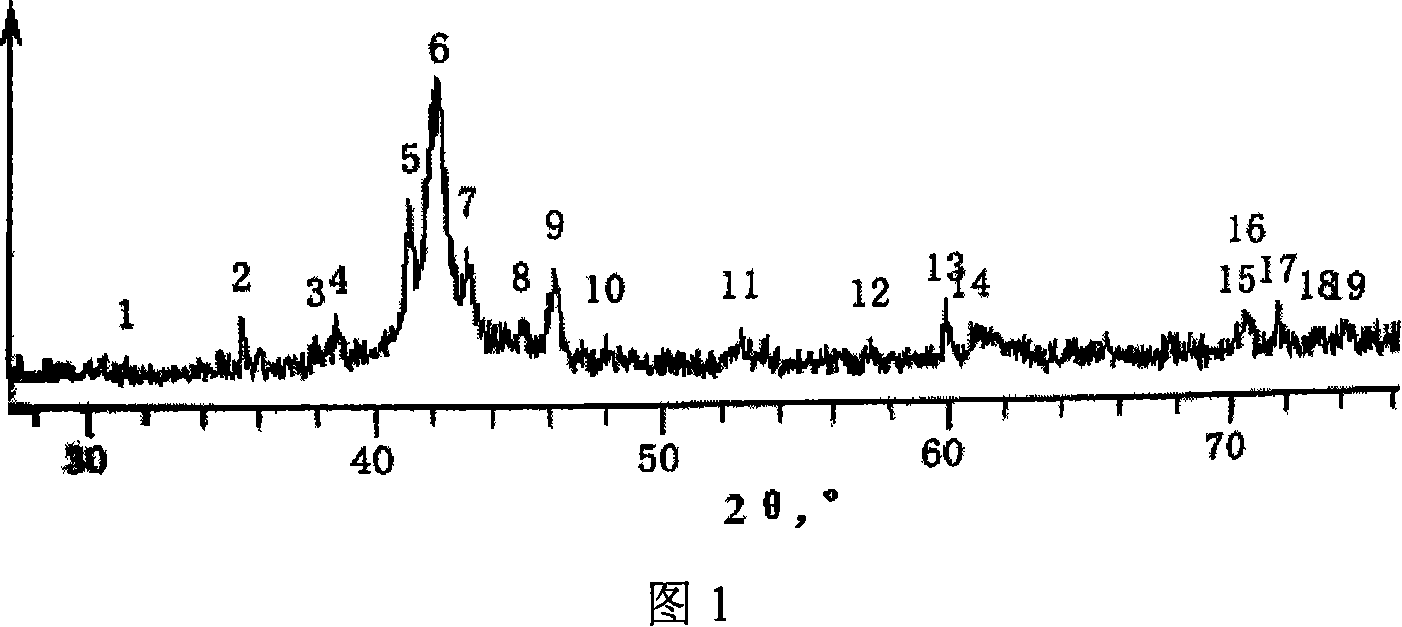

Image

Examples

Embodiment 1

[0025] The first step, mixing powder:

[0026] Powder raw materials: 99.0% purity, 300-mesh Ti powder, 99.6% purity, 300-mesh Ni powder.

[0027] No pore-forming agent was added (addition amount was 0).

[0028] Put the above powder into the powder mixer according to the ratio of titanium to nickel atomic ratio = 50:50, the speed of the powder mixer is 100 rpm, and the mixing time is 2 hours.

[0029] The second step, billet making:

[0030] Put the mixed powder into the mold cavity and press it into a billet, and the range of the applied pressure is 5MPa. 5% turpentine is added during pressing.

[0031] The third step, microwave synthesis:

[0032] Open the door of the microwave oven, put the gas chamber into the microwave oven, and connect the gas circuit.

[0033] Install the feed table, powder compact sample, initiator, and gas hood in sequence.

[0034] Close the furnace door and pass in an inert protective gas.

[0035] Set the microwave power and time, the sample...

Embodiment 2

[0042] The first step, mixing powder:

[0043] Powder raw materials: 99.5% purity, 300-mesh Ti powder, 99.7% purity, 250-mesh Ni powder.

[0044] Add 10% TiH pore-forming agent, TiH powder with a purity of 99.5% and a particle size of 300 mesh.

[0045] Put the above powder into the powder mixer according to the ratio of titanium to nickel atomic ratio = 50.5:49.5, the speed of the powder mixer is 200 rpm, and the mixing time is 4 hours.

[0046] The second step, billet making:

[0047] Put the mixed powder into the mold cavity and press it into a billet, and the range of the applied pressure is 30MPa. No excipients are added during the pressing process.

[0048] The third step, microwave synthesis:

[0049] Open the door of the microwave oven, put the gas chamber into the microwave oven, and connect the gas circuit.

[0050] Install the feed table, powder compact sample, initiator, and gas hood in sequence.

[0051] Close the furnace door and pass in an inert protective...

Embodiment 3

[0059] The first step, mixing powder:

[0060] Powder raw materials: 99.5% purity, 300-mesh Ti powder, 99.7% purity, 250-mesh Ni powder.

[0061] Add 10% (NH 4 ) 2 CO 3 Porogen, (chemically pure).

[0062] Put the above powder into the powder mixer according to the ratio of titanium to nickel atomic ratio = 50:50, the speed of the powder mixer is 300 rpm, and the mixing time is 12 hours.

[0063] The second step, billet making:

[0064] Put the mixed powder into the mold cavity and press it into a billet, and the range of the applied pressure is 60MPa. No excipients are added during the pressing process.

[0065] The third step, microwave synthesis:

[0066] Open the door of the microwave oven, put the gas chamber into the microwave oven, and connect the gas circuit.

[0067] Install the feed table, powder compact sample, initiator, and gas hood in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com