Thermoplasticity elastic sock processing method

A technology of thermoplastic elasticity and thermoplastic elastomer, which is applied in the direction of insoles, metal processing, footwear, etc., and can solve problems such as softness and poor resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

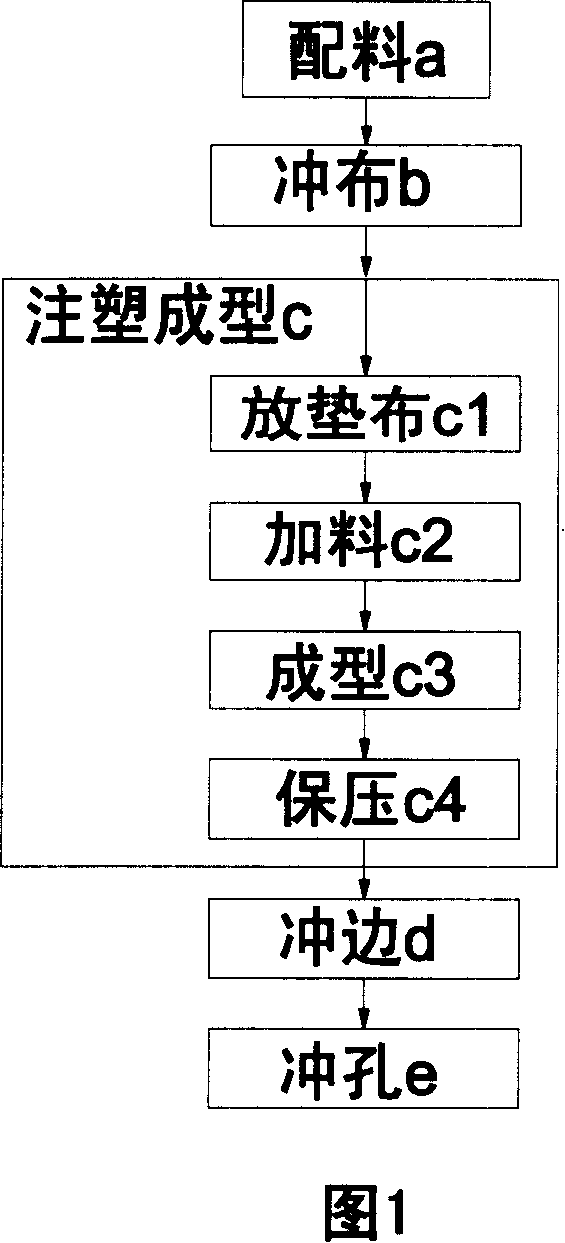

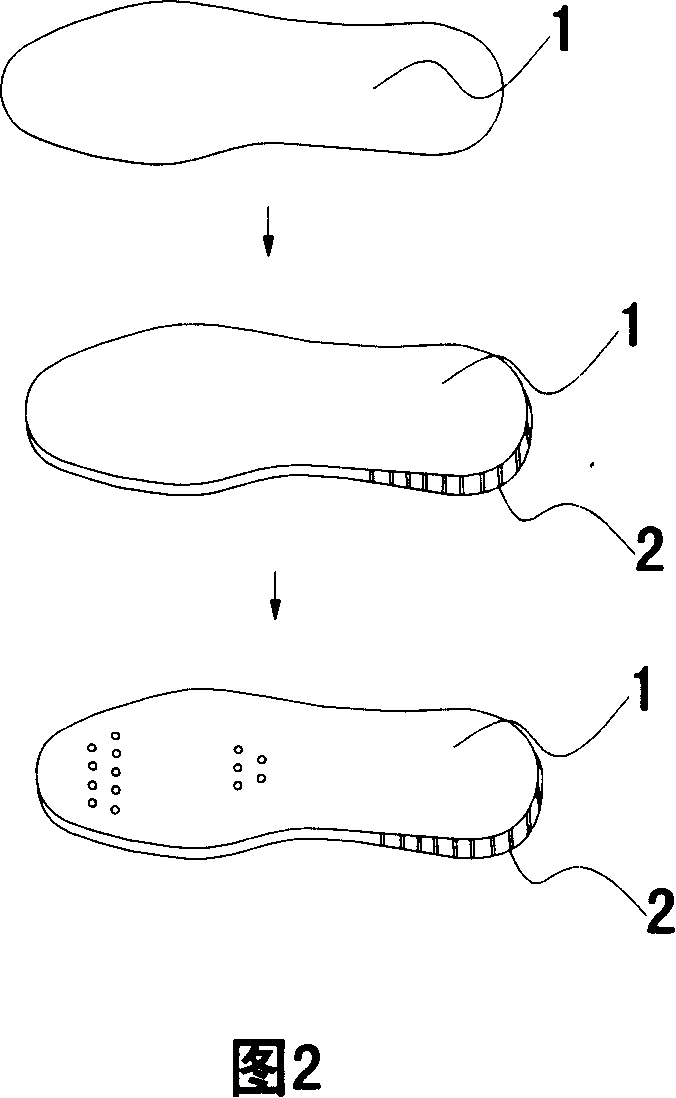

[0042] A processing method for thermoplastic elastic insoles, selects TPR thermoplastic elastomer (thermoplastic rubber) as the main raw material, TPR thermoplastic elastomer is to contain styrene-ethylene / butylene-styrene (SEBB) polymer as the main raw material, and naphthene It is made by mixing oil and other polymers (such as PP) in a certain proportion. The processing method adopts the following processing steps, as shown in Figures 1 and 2:

[0043] a. Ingredients: TPR thermoplastic elastomer and toner, according to the weight ratio of 10000:8 or 10000:12 or 10000:16, preferably 10000:12; kneading into the kneader for 20 or 30 or 40 minutes, the best kneading time is 30 minutes;

[0044] b. Cloth punching: the cloth base material is punched and cut into the shape of the insole mold required to form the pad cloth 1 (consistent with the shape of the insole). The cloth base material in this embodiment is a composite cloth, which is made of one layer of velvet and a white pa...

Embodiment 2

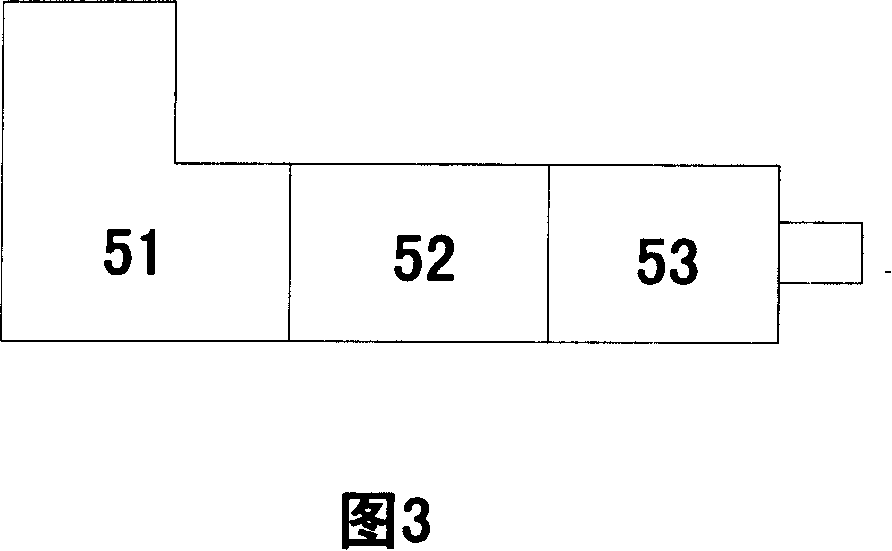

[0056] A method for processing a thermoplastic elastic insole. The difference between this embodiment and the first embodiment is that the thermoplastic elastic insole of the present invention is a two-color insole, which includes an insole 1, an insole body 2 and a small insole 3 from top to bottom; this embodiment The shoe-pad body 2 color of the thermoplastic elastic insole of example is different from the shoe-pad small piece 3 colors. When injecting two-color insoles, it is two injection moldings; according to the structural requirements of the insoles, a lower mold and two upper molds are designed. The injection molding process is as follows, as shown in Figures 4 and 5:

[0057] a. Ingredients: TPR thermoplastic elastomer and toner, according to the weight ratio of 10000:8 or 10000:12 or 10000:16, preferably 10000:12; kneading into the kneader for 20 or 30 or 40 minutes, the best kneading time is 30 minutes;

[0058] b. Cloth punching: the cloth base material is punche...

Embodiment 3

[0074] A method for processing a thermoplastic elastic insole, the difference between this embodiment and the second embodiment is that the thermoplastic elastic insole of the present invention is a three-color insole, including a pad 1, an insole body 2, a middle insole 4 and a small insole 3, Among them, the insole middle part 4 has a through groove, the insole small part 3 is located in the through groove of the insole middle part 4, the insole body 2 is located under the pad cloth 1, the insole small part 3 and the insole middle part 4 are located under the insole body 2 ; The thermoplastic elastic insole of the present embodiment has 2 colors of the insole body, 3 colors of the small insole, and 4 colors of the middle part of the insole. When injecting three-color insoles, it is three-time injection molding; according to the structural requirements of the insole, design a lower mold, two upper molds, and another set of middle molds; the injection molding process is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com