Three-filum open arc welding method

A welding method and welding direction technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high investment cost, poor flexibility, increased investment cost, etc., achieve simple process realization, improve welding speed, and improve welding The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

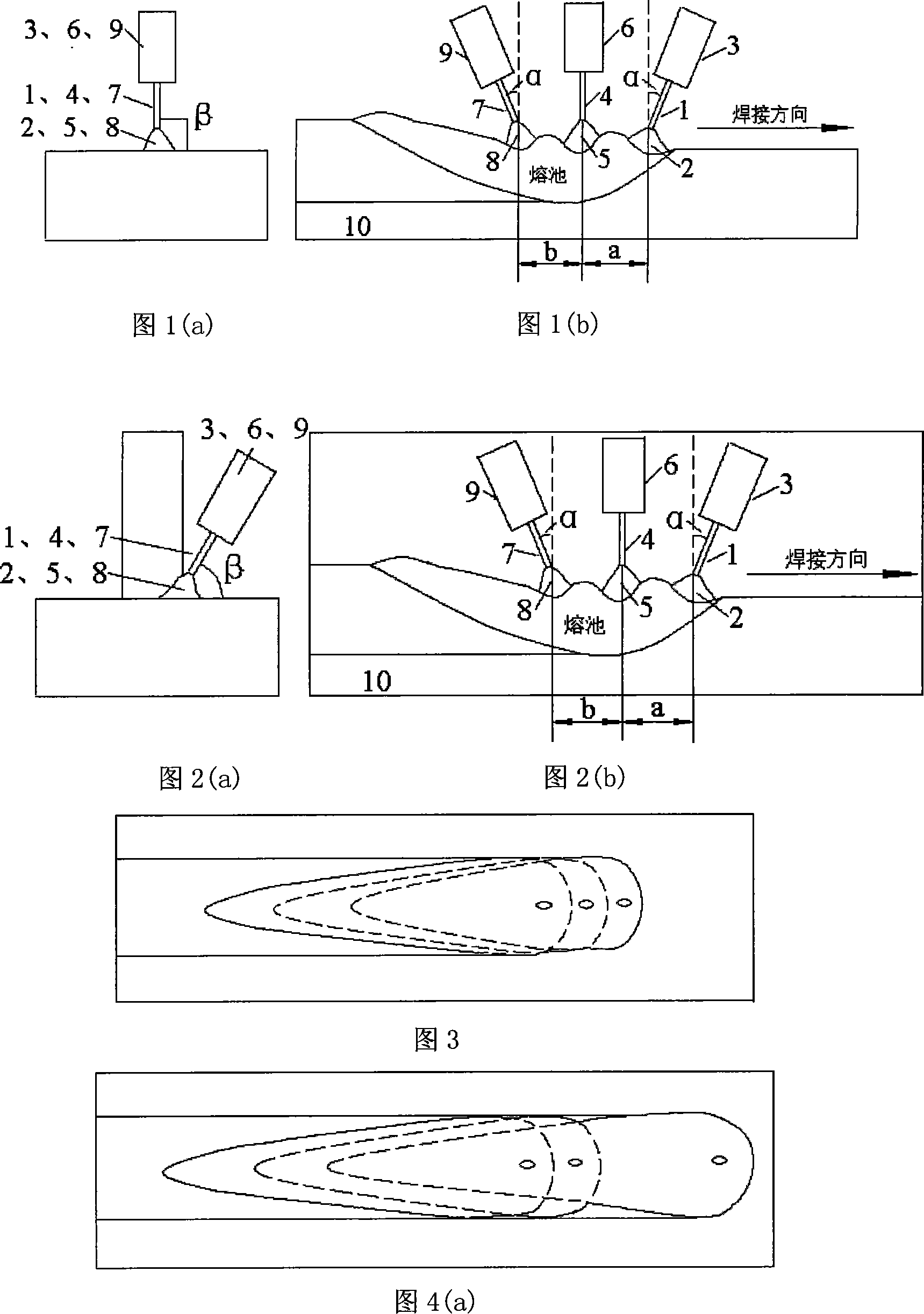

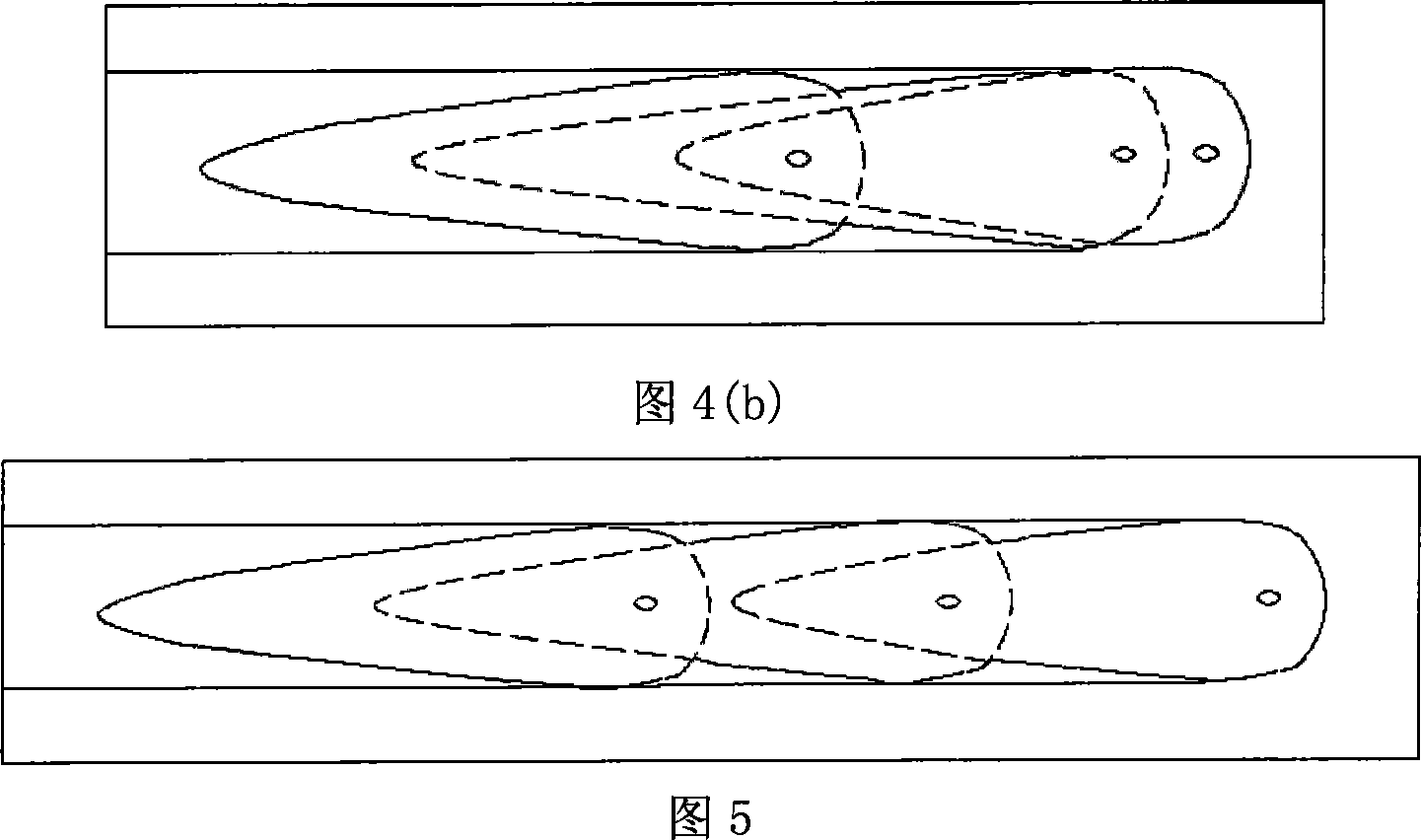

[0025] When welding flat plates in ship structures, the thickness of the steel plates is 15mm, and the shielding gas is 100% CO 2 , the welding machine is Panasonic 500GR3, and its process parameters are: the welding wire grade is MX-200H, the welding wire diameter is Ф1.2mm, the welding voltage of the three welding wires is 32V, the welding current is 320V, the dry elongation is 12mm, and the gas flow rate is 15L / min, the welding power supply is connected to the negative pole of the workpiece, and the positive pole of the welding torch. The angle α between the leading welding torch, the following welding torch and the vertical direction of the workpiece is 15°, and the middle welding torch is perpendicular to the workpiece. The leading welding torch, the middle welding torch and the following welding torch are arranged longitudinally, and the angle β with the horizontal direction of the workpiece is 90°. The distance between the leading welding torch and the middle welding t...

Embodiment 2

[0027] For the fillet welding of the rib reinforcement plate, the thickness of the plate is 15mm, the thickness of the rib reinforcement plate is 10mm, and the shielding gas is 100% CO 2 , the welding machine is Panasonic 500GR3, and its process parameters are: the welding wire grade is MX-200H, the welding wire diameter is Ф1.6 mm, the voltage of the leading welding torch is 36V, the voltage of the middle welding torch is 31V, the voltage of the following welding torch is 28V, the leading welding torch The current of the welding torch is 400A, the current of the middle welding torch is 310A, and the current of the following welding torch is 260A. The dry elongation of the welding wire is set to 20mm, the gas flow rate is 20L / min, the welding power supply is DC positive connection, the angle α between the leading welding torch, the following welding torch and the middle welding torch is 15°, the leading welding torch, the middle welding torch and the following welding torch Arra...

Embodiment 3

[0029] For the fillet welding of the rib reinforcement plate, the thickness of the plate is 15mm, the thickness of the rib reinforcement plate is 10mm, and the shielding gas is 100% CO 2 , the welding machine is Panasonic 500GR3, and its process parameters are: the welding wire grade is MX-200H, the welding wire diameter is Ф1.6mm, the voltage of the leading welding torch is 36V, the voltage of the intermediate welding torch is 35V, the voltage of the following welding torch is 30V, the leading welding torch The current is 390A, the current of the middle welding torch is 390A, and the current of the following welding torch is 280A. The dry elongation of the welding wire is set to 20mm, the gas flow rate is 20L / min, the welding power supply is DC positive connection, the angle α between the leading welding torch, the following welding torch and the middle welding torch is 15°, the leading welding torch, the middle welding torch and the following welding torch Arranged longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com