Combustor implementing ultra-low oxidized burning loss during heating steel billet

A billet heating and burner technology, used in burners, gas fuel burners, combustion methods, etc., can solve problems such as limited potential and insignificant effects, and achieve the effects of long service life, simple structure and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

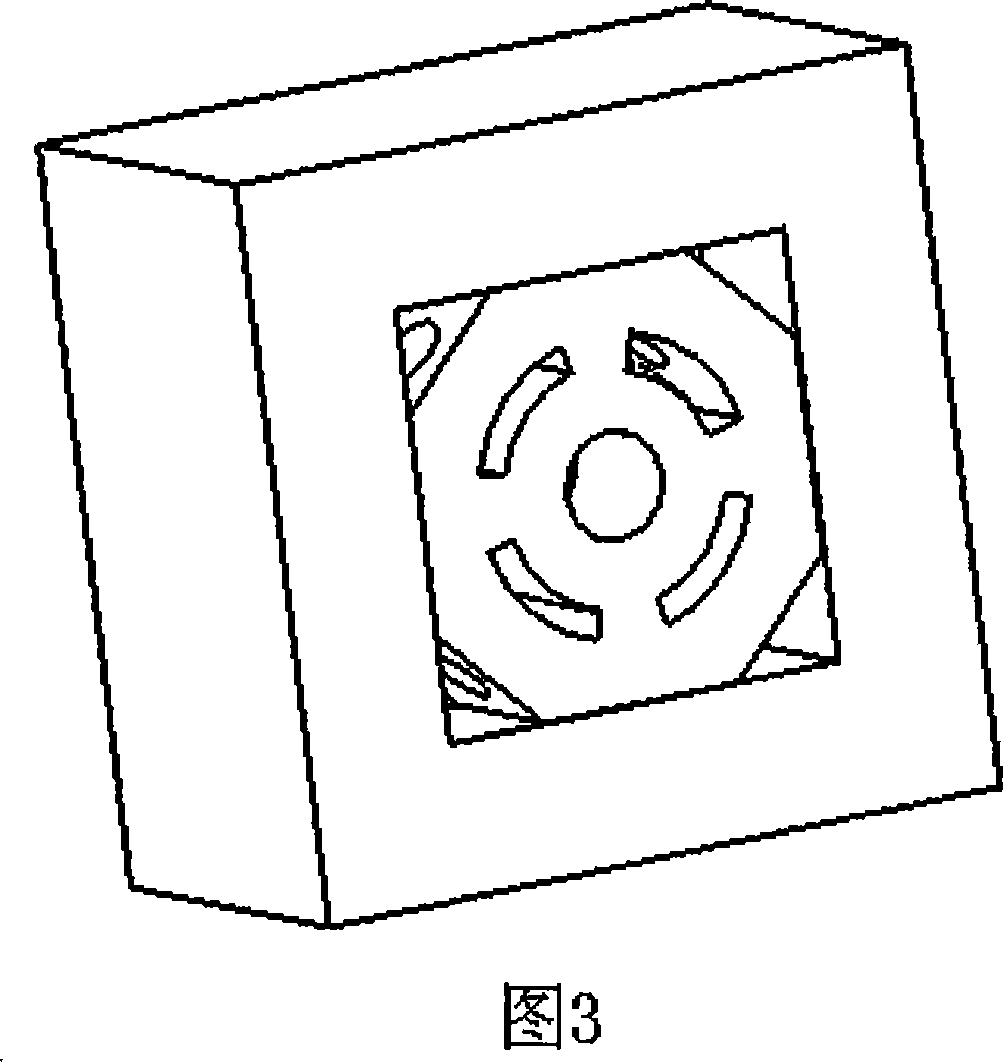

[0019] In Fig. 1, the burner has a mounting plate 1, a burner brick 2 in front of the mounting plate, a burner shell 3 behind the mounting plate, and a gas supply channel 4 at the center line of the mounting plate and the burner shell, which is connected with the gas The annular channel formed by the channel is the air channel 5, and the air channel in the burner brick is divided into four parts 6, corresponding to the four air nozzles 7 of the burner brick, each air channel has a side hole 8, when the burner is installed, The end of the burner brick is coplanar with the inner side of the furnace wall, and there is no part that goes deep into the furnace. The burner works like this: after the gas enters from the gas channel 9, it is directly sprayed into the furnace through the gas nozzle 11, after the preheated air enters from the air inlet 10, after passing through the annular air channel, it enters the burner brick and distributes it equally. The four air passages are spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com