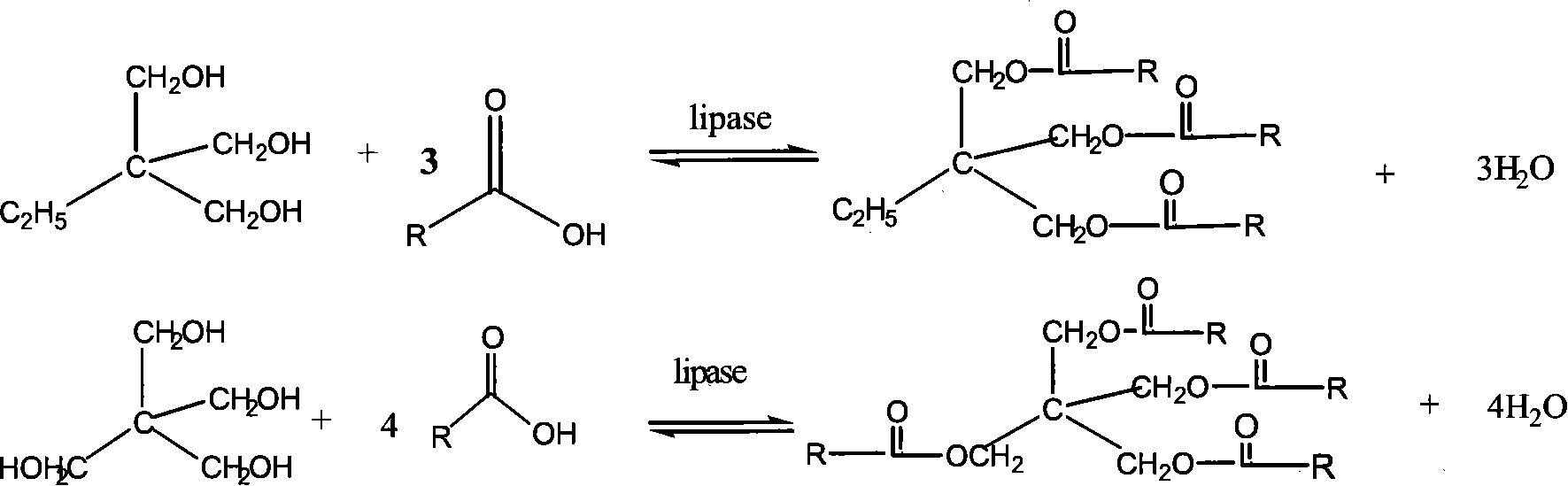

Method for catalyzing and synthesizing polyalcohol ester by immobilized lipase

A technology for immobilizing lipase and polyol ester, applied in lubricating compositions, base materials, fermentation, etc., can solve the problems of complex production process, side reactions, product pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation and immobilization of embodiment 1 lipase

[0052] The immobilized enzyme refers to the applicant's co-pending Chinese invention patent application No.200510112638.5 and Tan TW, Zhang M, Wang BW, Ying CH, Deng L.Screening of high lipase producing Candida sp.and production oflipase by fermentation.Process Prepared by the method in Biochem 2003; 39(4): 459-65, hereinafter the same.

[0053] The cotton cloth and the co-fixative agent are mixed according to the mass volume ratio of 1:1, and dried at room temperature to obtain the activated carrier. Co-fixative is PEG6000, coconut oil, Tween 80, gelatin, lecithin and magnesium sulfate mixture, and its mass ratio is gelatin: lecithin: PEG6000: Tween 80: magnesium sulfate: coconut oil=5: 1: 1: 2 :1:1. The prepared Yarrow lipolytica lipase aqueous solution is mixed with the activated carrier at a ratio of 8000 U / g activated carrier, soaked, and dried at room temperature to obtain immobilized lipase.

[0054] Acid...

Embodiment 23~25

[0058] Embodiment 23~25 solvent-free system

[0059] Unless otherwise specified, all yields in the examples of the present invention are measured by gas chromatography (GC) method.

Embodiment 2

[0060] Embodiment 2: the immobilized enzyme prepared in 0.5g embodiment 1 adds in the 5ml normal hexane that contains 0.134g trimethylolpropane and 0.847g (alcohol of 3 times material amount) oleic acid, organic solvent water content is 0.5 %, at 40°C, shake the reaction. After 24 h the conversion of polyol reached 63.145% (measured by gas chromatography (GC)).

[0061] Embodiment 2: the immobilized enzyme prepared in 0.5g embodiment 1 is added in the 5ml isooctyl alcohol that contains 0.134g trimethylol propane and 0.433g (alcohol of 3 times material amount) octanoic acid, organic solvent water content is 0.5 %, at 40°C, shake the reaction. After 24 hours, the conversion rate of polyols reached 60.61%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com