Grignard reaction method in production of maltol

A Grignard reaction and maltol technology, which is applied in the production field of maltol, can solve the problems of difficult operation control, long production cycle, high reaction pressure, etc., and achieve the goal of improving product yield, high equipment utilization rate, and product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

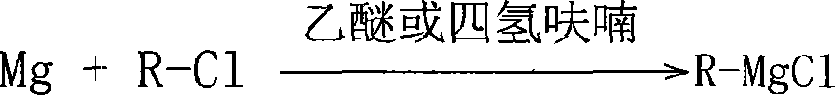

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Put 60Kg of magnesium chips into the Grignard reaction kettle (30L of Grignard reagent has been reserved), seal the feeding hole, pour in 1200L of anhydrous ether (or tetrahydrofuran) solvent, and then vacuum to minus 0.04-minus 0.06Mpa, and then 40Kg of methyl chloride. (No steam heating is required. Sometimes the water in the solvent is too high. You can heat it slightly to shorten the initiation time.) The reaction starts on its own. The kettle temperature rises from about 30 degrees to about 83 degrees. Minus 0.04Mpa rises to about 0.2Mpa. At this time, open the jacket cooling water to control the temperature to be less than 80 degrees, continue to pass in the methyl chloride reaction, the methyl chloride is passed to 130Kg, and the natural reaction is half an hour, then the cooling water can be turned on and the temperature of the kettle is reduced. Decrease to about 30 degrees, vent and release the pressure, pass in nitrogen protection, discharge the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com