Anodising aluminium alloy

An anodizing and aluminum alloy technology, applied in anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve problems such as not suitable for bonding, and achieve the effect of superior peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

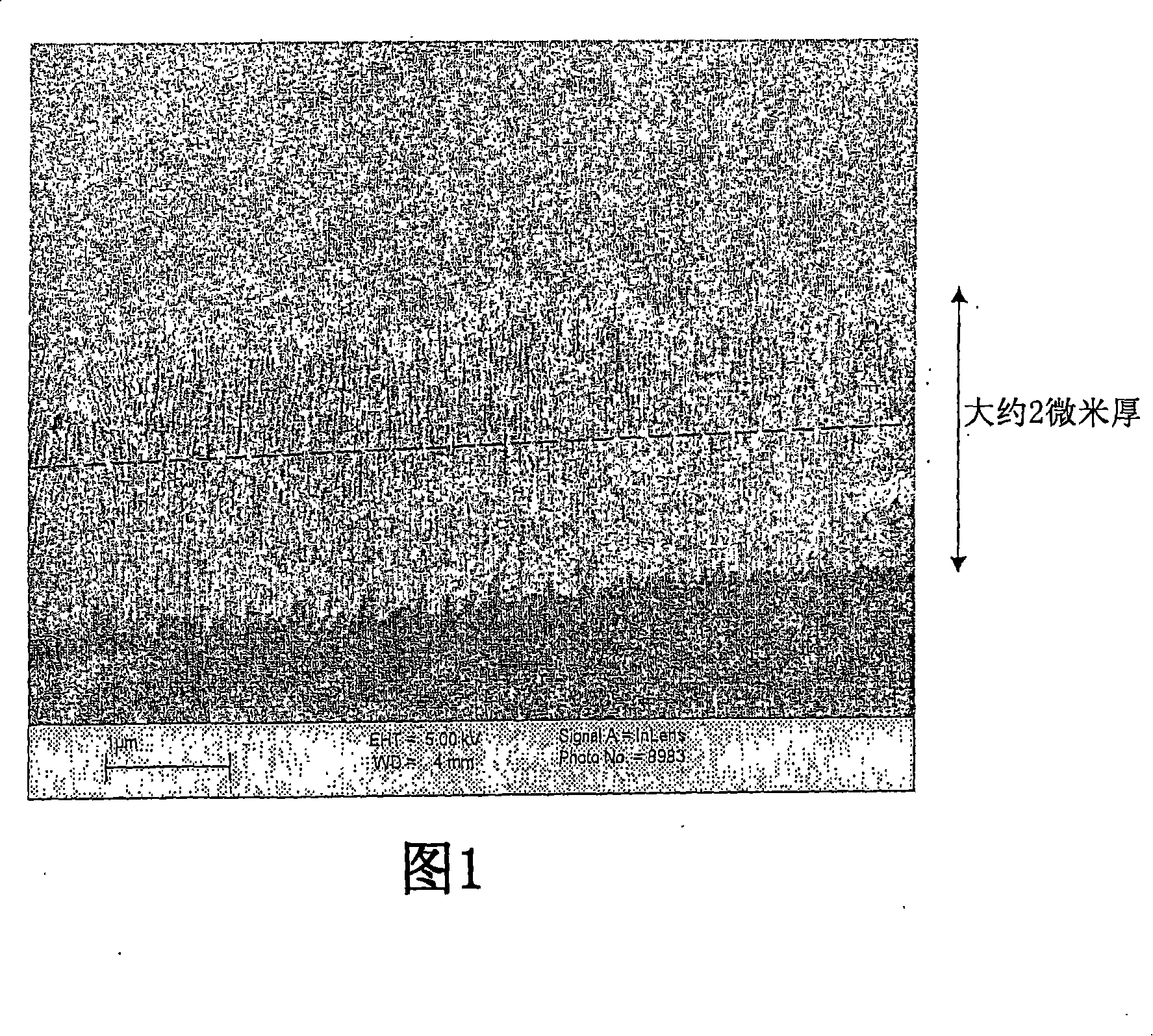

[0038] A bare 2024 aluminum alloy workpiece was connected to the anode of an anodized cell having a series of cathodes along the cell walls. No degreasing or deoxidizing treatment is applied to the workpiece prior to anodizing. The anodizing solution contained 2.5% sulfuric acid and 2.5% phosphoric acid. The cell was maintained at a temperature of 35°C. The workpiece was anodized for 120 seconds using a single phase AC current of 50 Hz, 15 volts. Immediately thereafter, DC anodization was performed in the same cell for 600 seconds with a DC current of 20 volts. After anodizing, wash the workpiece in water to remove traces of the anodizing solution. Examination of the resulting anodized film revealed a film with a dual structure in which the thickness of the outer layer was about 0.5 microns and the diameter of the pores was about 30 nanometers. The thickness of the inner layer is about 1.5 microns, which is substantially non-porous, as shown in FIG. 1 .

[0039] Especiall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com