Boroxine derivatives as flame retardant

A technology of boroxine ring and alkoxy boroxine, which is applied in the field of thermosetting polymer resin and can solve the problems of lack of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] All tests are performed according to IPC TM650.

[0081] The IPC test method is the following electrical laminate industry standard (The Institute For Interconnection and Packaging Electronic Circuits, 3451 Church Street, Evanston, Illinois 60203):

[0082] method

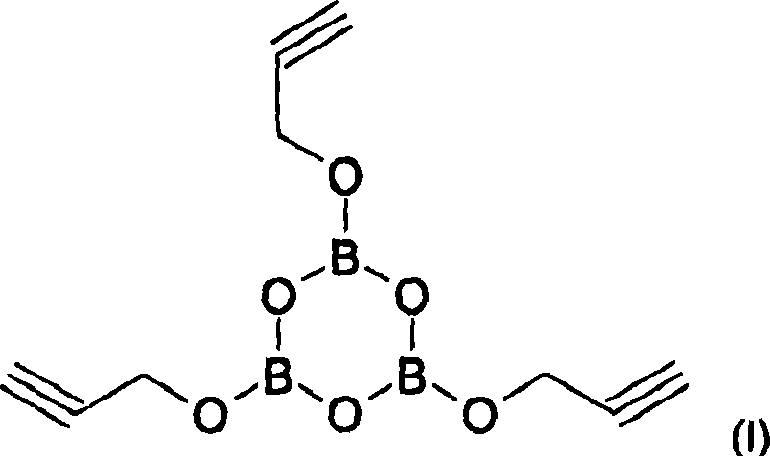

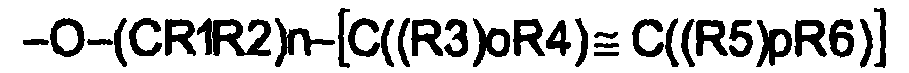

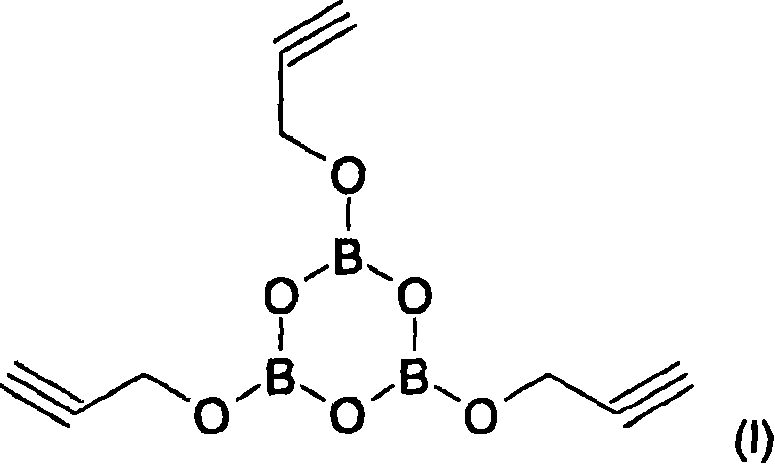

[0083] A) Preparation of Tripropargylboroxine (Compound (I))

[0084] A mixture of 3 moles of propargyl alcohol and 1 mole of trimethoxyboroxine is heated to a temperature of 120-150° C. until distillation of methanol ceases.

[0085] Boiling point: 85-88°C (10mm Hg pressure)

[0086] B) Laminates

[0087] Fiberglass laminate composites were prepared by a solvent impregnation method. The components are dissolved in solvent and then coated onto 7628 fabric, an industry standard fiberglass fabric (Procher SA 7628 with silane or polyimide) defined by the glass strip, thickness and weight of the glass fabric. amine finish). The solvent is then evaporated and the composition is B-staged. The prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com