Whey product and process

A whey and whey protein technology, applied in dairy products, other dairy products, whey, etc., can solve problems such as attempts to hinder cold gelation of WPC, and achieve wide practicability and increase protein content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

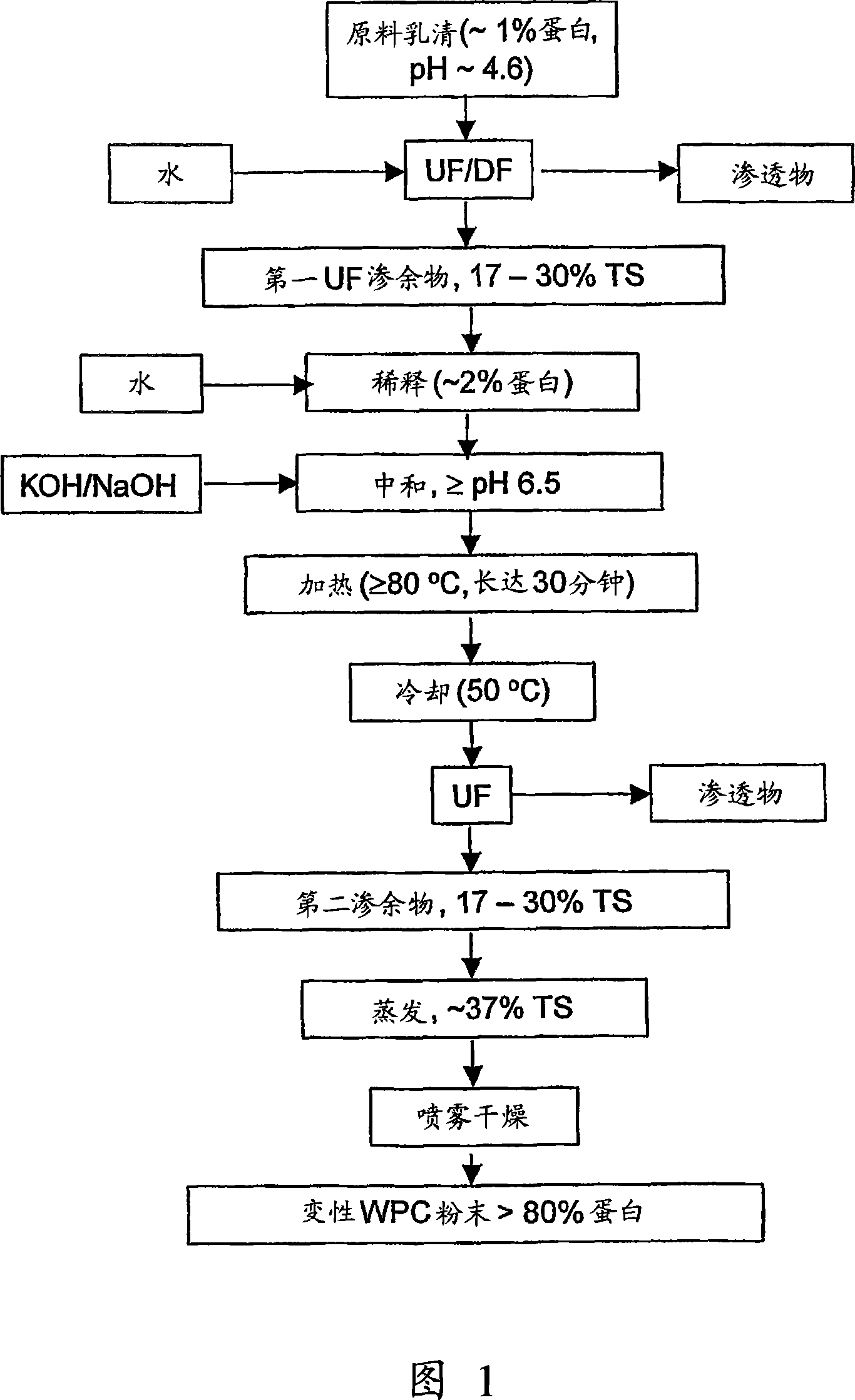

Image

Examples

Embodiment 1

[0056] Example 1 demonstrates the formation of low molecular weight aggregates during heating

[0057] The addition of 10% sulfuric acid to skim milk produces an acidic precipitation of casein, from which raw whey is obtained which contains about 1% protein and has a pH of about 4.6. The raw whey was ultrafiltered until the solids content was about 20% total solids. The retentate was diluted with purified water to provide a diluted retentate containing 2% protein. The pH was adjusted to 7.0 or 7.5 with 10% KOH (w / v). The pH adjusted diluted retentate was heated to 80°C for 30 minutes. Samples were taken and subjected to native-PAGE (Havea, P., Singh, H., Creamer, L.K. & Campanella, O, H. Electrophoretic characterization of the protein products formed during heat treatment of wheyprotein concentrate solutions Electrophoretic characterization of the protein product formed). Journal of Dairy Research, 65, 79-91, 1998). These results show (Fig. 5) that the amount of β-lactoglo...

Embodiment 2

[0058] Example 2 confirms that the present invention can provide WPC with different levels of protein denaturation

[0059] The method shown in FIG. 2 provides raw whey containing about 1% protein and having a pH of about 4.6 obtained from acidic precipitation of casein produced from skim milk by adding 5% sulfuric acid. After clarification, the whey was ultrafiltered until the solids content was about 20% total solids. The retentate was diluted with water to provide a dilute solution containing 2% protein, then the pH was adjusted to 6.9 with 10% (w / v) KOH.

[0060] The diluted whey protein solution was divided into two streams and then heated at two different operating levels, namely operation 1: 74°C for 20 min, or operation 2: 82°C for 21 min. The hot whey stream was then cooled to 50°C and ultrafiltered to provide secondary retentate lots containing about 20% total solids. The retentate stream was then spray dried. The final powder was analyzed and compared to a standa...

Embodiment 3

[0065] Example 3 demonstrates the importance of keeping the hot retentate at 40 to 60°C

[0066] Two cartridges (1 L) of hot retentate (about 20% total solids) were obtained from run 2 of Example 2 above. One cylinder was stored at 20°C, while the other cylinder was stored at 50°C. The protein solution in the cartridge stored at 20°C started to form a fairly thick to strong gel within 1 h. The protein solution was discarded as it was too thick for further processing. The protein retentate kept in the drum at 50°C was still in solution for more than 3h. This time delay allows further processing of the solution under industrial production conditions before gel formation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com