Production method of cold-foaming fly ash unfired ceramsite

A production method and technology of fly ash, applied in ceramic products, sustainable waste treatment, solid waste management, etc., can solve the problems of high water absorption, low strength, brine return, etc., achieve good product quality, reduce production costs, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

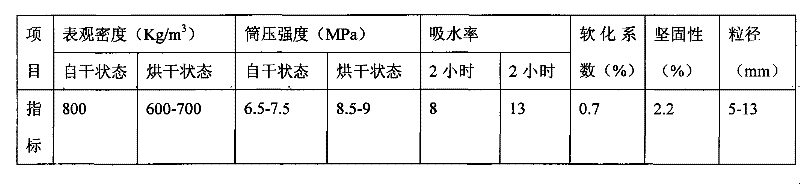

Embodiment 1

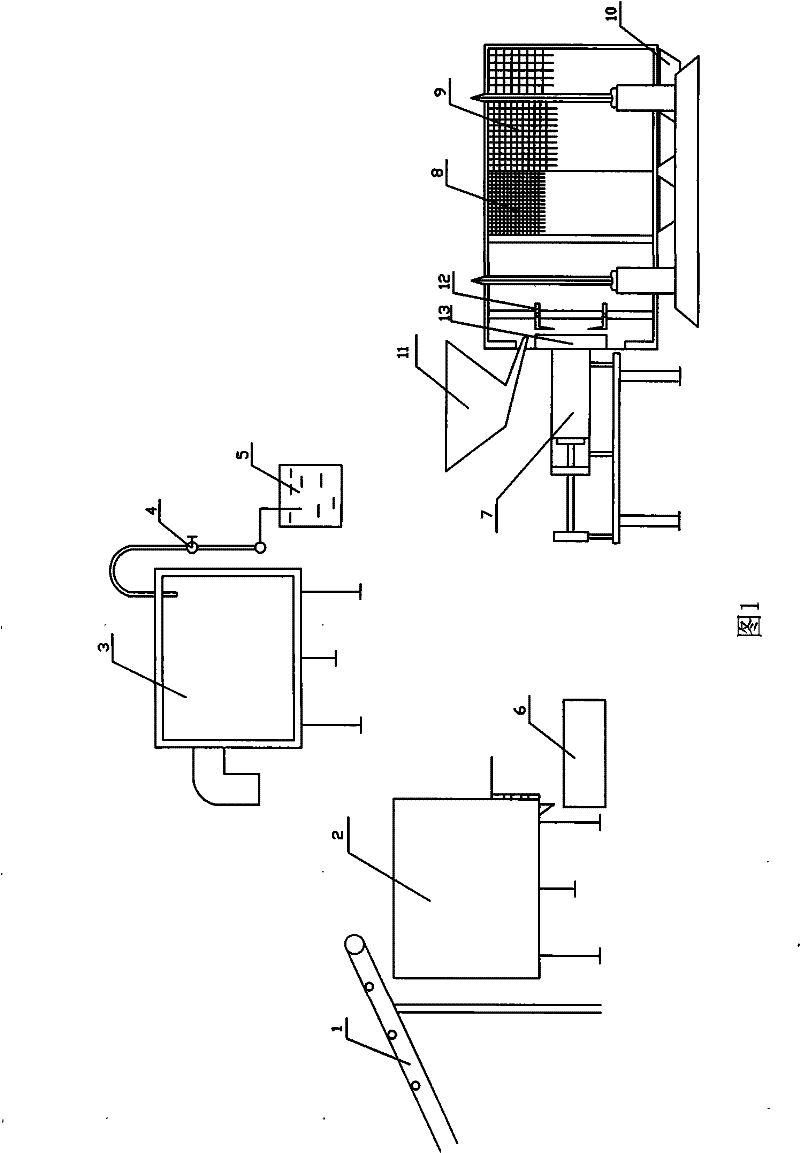

[0016] Describe the specific process of the present invention in detail below in conjunction with accompanying drawing.

[0017] 1) preparation of mixed slurry;

[0018] After the fly ash is wheel-milled, pass through a 80-100 mesh sieve, mix with a mixer according to the mass ratio of fly ash, cement, and sodium silicate 1.5:1:0.2, and then add a certain amount of water-based resin calcium polyacrylate, water , admixture; water-based resin calcium polyacrylate is 1% by weight of cement, and water is 55% by weight of the above-mentioned mixture; the effect of admixture is waterproof; accelerate the solidification of concrete and increase strength; the addition is 2-2% of the amount of cement 3%, admixture made of bile alum CuSO 4 ·5H 2 O, red alum K 2 Cr·O 11 2H 2 O, alum KAl(SO 4 ), purple alum KCr (SO 4 ) 2 Mixed, according to the weight ratio of 1:1:1:1, add 60 times the weight of the above four mixtures of water, 400 times the weight of the above four mixtures of s...

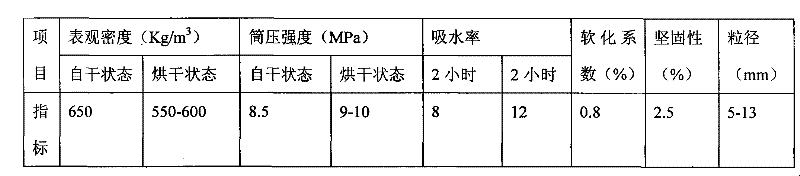

Embodiment 2

[0026] 1) preparation of mixed slurry;

[0027] Magnesium oxychloride cement is used as the cementitious material, and the specific materials are in parts by weight: 50 parts of fly ash, 40 parts of magnesium oxide, 13-15 parts of anhydrous magnesium sulfate, 3 parts of anhydrous magnesium chloride, 5 parts of additive calcium sulfate, 0.6 part of melamine resin, and the amount of water added is 60% of the above-mentioned total weight.

[0028] 2) The foaming liquid foams;

[0029] Add a commercially available foaming agent (rosin alkali saponin) into the foaming tank at a mass ratio of 1:25 to water, and perform mechanical foaming. The foaming time is 3-5 minutes. At this time, a fine white and uniform foam is obtained, and then add The foam-fixing agent is solidified after half a minute;

[0030] 3) Mixing, extruding, cutting and forming of pulp and bubbles;

[0031] Mix the above-mentioned slurry and foam, and carry out mechanical mixing according to the volume ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com