Method for baking clay ceramsite by using biological sludge of sewage treatment plant

A sewage treatment plant and biological sludge technology, which is applied in the field of using sewage treatment plant biological sludge to burn clay ceramsite, can solve the problems of incapable of resource utilization, occupation of large land, serious environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

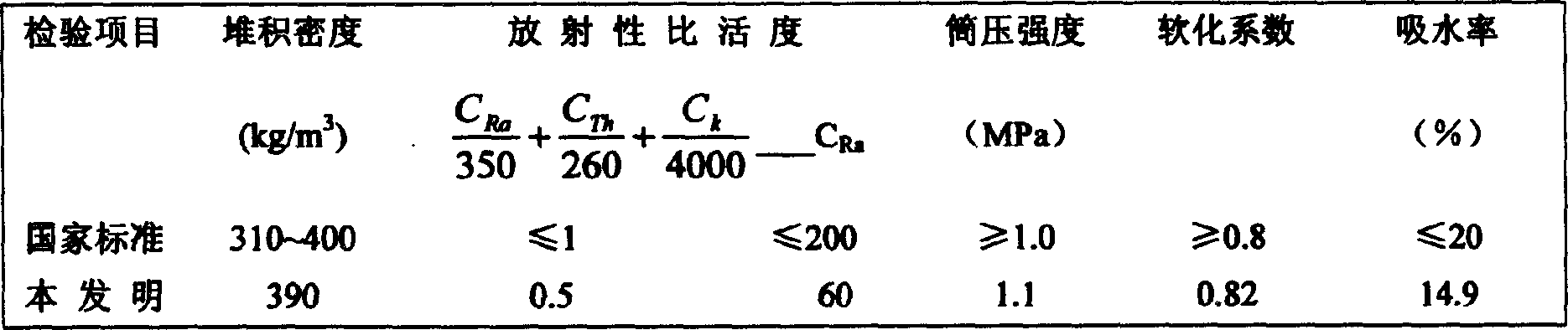

Image

Examples

Embodiment 1

[0040]Example 1 wet sludge 34.90 30.35 11.58 4.44 1.82 0.95 2.54 1.47 5.16 72.50

Embodiment 2

[0041] Example 2 wet sludge 42.39 21.45 8.89 3.57 2.42 0.96 2.09 1.46 4.88 85.00

Embodiment 3

[0042] Example 3 wet sludge 56.90 7.08 3.39 2.63 1.52 1.10 1.75 1.25 7.61 77.30

[0043] Wet Clay 10.00 59.89 17.43 8.62 2.21 1.61 29.70

[0044] Iron powder 13.13 17.23 5.87 60.82 3.28 2.64

[0045] Limestone powder 39.70 6.98 1.34 0.69 49.28 1.32

[0046] Embodiment 1 Bituminous coal ash 47.73 28.68 8.83 5.99 2.48

[0047] Embodiment 2 Bituminous coal ash 55.38 25.15 6.56 4.85 2.93

[0048] Embodiment 3 Bituminous coal ash 63.46 22.65 4.73 3.79 2.37

[0049] Industrial analysis (weight %) and heat value of table 4 fuel

[0050] fuel f A f V f C f Q f DW (kJ / kg)

[0051] Embodiment 1 bituminous coal 4.19 16.04 26.90 56.47 27632

[0052] Embodiment 2 bituminous coal 5.45 20.24 27.15 53.63 26237

[0053] Embodiment 3 bituminous coal 6.58 23.19 28.03 49.10 25865

[0054] In Example 1, the flow rate of the wet biological sludge of Guangzhou Liede Sewage Treatment Plant in the screw feeder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com