Riverway bottom mud ecological brick for riverway restoration work and preparing method thereof

A technology for river bottom mud and river restoration, which is applied in applications, household utensils, clay products, etc., can solve the problem of resource utilization of heavy metal river bottom mud, and achieve the effect of saving clay resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

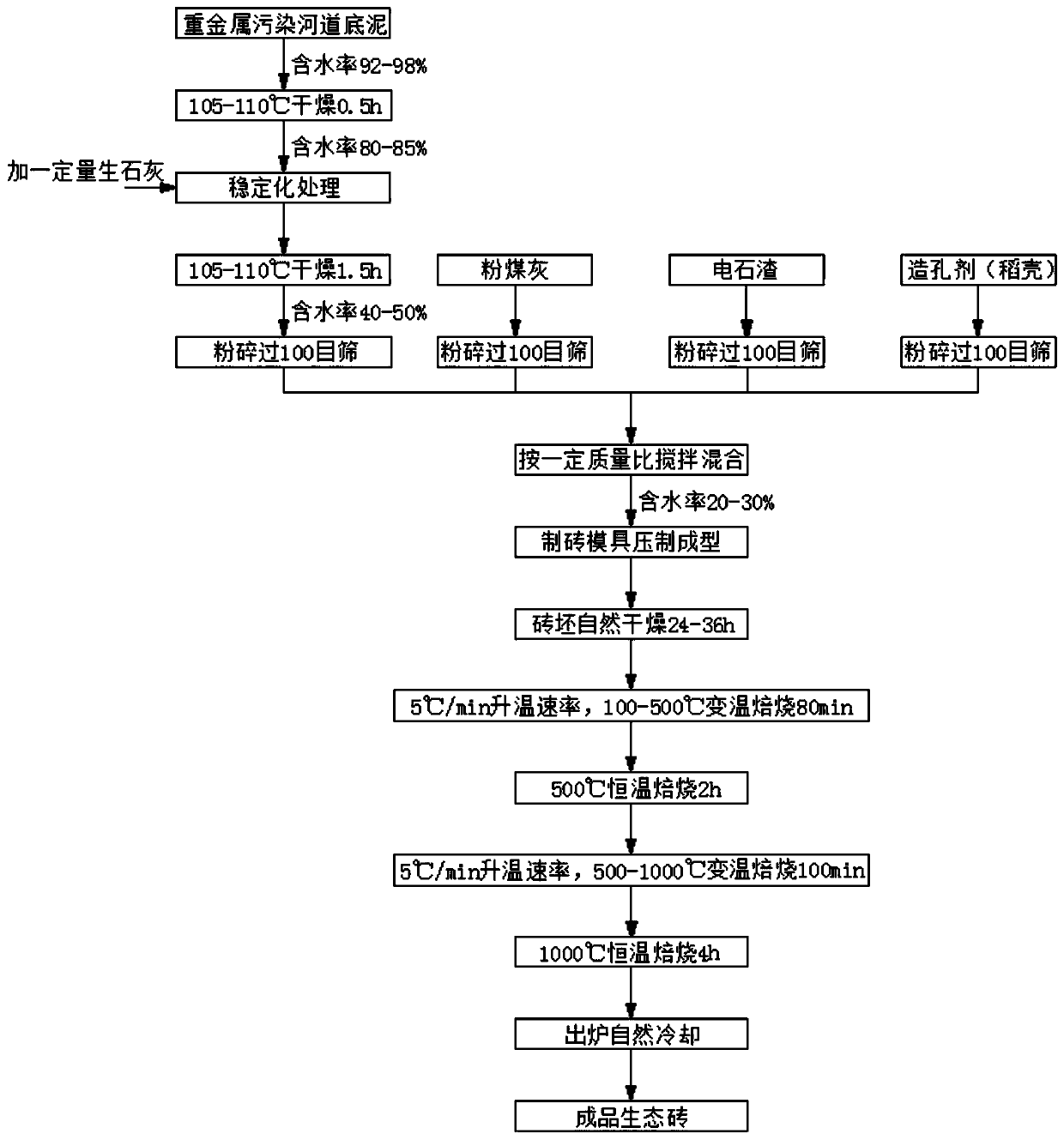

[0022] For the river bottom mud ecological bricks used in river restoration projects prepared in this embodiment, firstly, the river bottom mud with a water content of about 92-98% is dehydrated and dried to obtain dry bottom mud with a water content of 45-50%, and then the above-mentioned 75% dry bottom mud, 10% fly ash, 10% calcium carbide slag and 5% pore-forming agent rice husk powder are sintered as the main raw materials. The specific preparation process is as follows:

[0023] (1) Initial dehydration of raw materials: The dredged heavy metal polluted river sediment with a moisture content of 92-98% is blast-dried at 105-110°C for 0.5h to obtain a sediment with a moisture content of 80-85%.

[0024] (2) Heavy metal stabilization treatment: 9.7Kg of the bottom sludge obtained in (1) and 0.3Kg of quicklime were stirred and mixed for 30 minutes in a stirring mixing tank to prepare bottom sludge with a water content of 70-75%.

[0025] (3) Re-dehydration of raw materials: bl...

Embodiment 2

[0033] The ecological bricks for heavy metal-contaminated river bottom mud in river restoration projects prepared in this embodiment first dehydrate and dry the river bottom mud with a water content of about 92 to 98% to obtain dry bottom mud with a water content of 45 to 50%, and then use the The above-mentioned mass ratio of 80% dry bottom mud, 8% fly ash, 8% carbide slag and 4% pore-forming agent rice husk powder is sintered as the main raw materials. The specific preparation process is as follows:

[0034] (1) Initial dehydration of raw materials: The dredged heavy metal polluted river sediment with a water content of 92-98% is blast-dried at 105-110°C for 0.5h to obtain sludge with a water content of 80-85%.

[0035] (2) Heavy metal stabilization treatment: 9.8Kg of the bottom sludge obtained in (1) and 0.2Kg of quicklime were stirred and mixed for 30 minutes in a stirring mixing tank to obtain bottom sludge with a water content of 70-75%.

[0036] (3) Re-dehydration of r...

Embodiment 3

[0044] The ecological bricks for heavy metal-contaminated river bottom mud in river restoration projects prepared in this embodiment first dehydrate and dry the river bottom mud with a water content of about 92 to 98% to obtain dry bottom mud with a water content of 45 to 50%, and then use the The above-mentioned mass ratio of 85% dry bottom mud, 6% fly ash, 6% carbide slag and 3% pore-forming agent rice husk powder is sintered as the main raw materials. The specific preparation process is as follows:

[0045] (1) Initial dehydration of raw materials: The dredged heavy metal polluted river sediment with a water content of 92-98% is blast-dried at 105-110°C for 0.5h to obtain sludge with a water content of 80-85%.

[0046] (2) Heavy metal stabilization treatment: 9.8Kg of the bottom sludge obtained in (1) and 0.2Kg of quicklime were stirred and mixed for 30 minutes in a stirring mixing tank to obtain bottom sludge with a water content of 70-75%.

[0047] (3) Re-dehydration of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com