Liquid crystal mixture used for polymerization alignment manufacture process and method for manufacturing liquid crystal display board

A mixture and liquid crystal technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as cost increase, process difficulty, and improvement, and achieve the effects of improving stability, improving polymerization effect, and improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

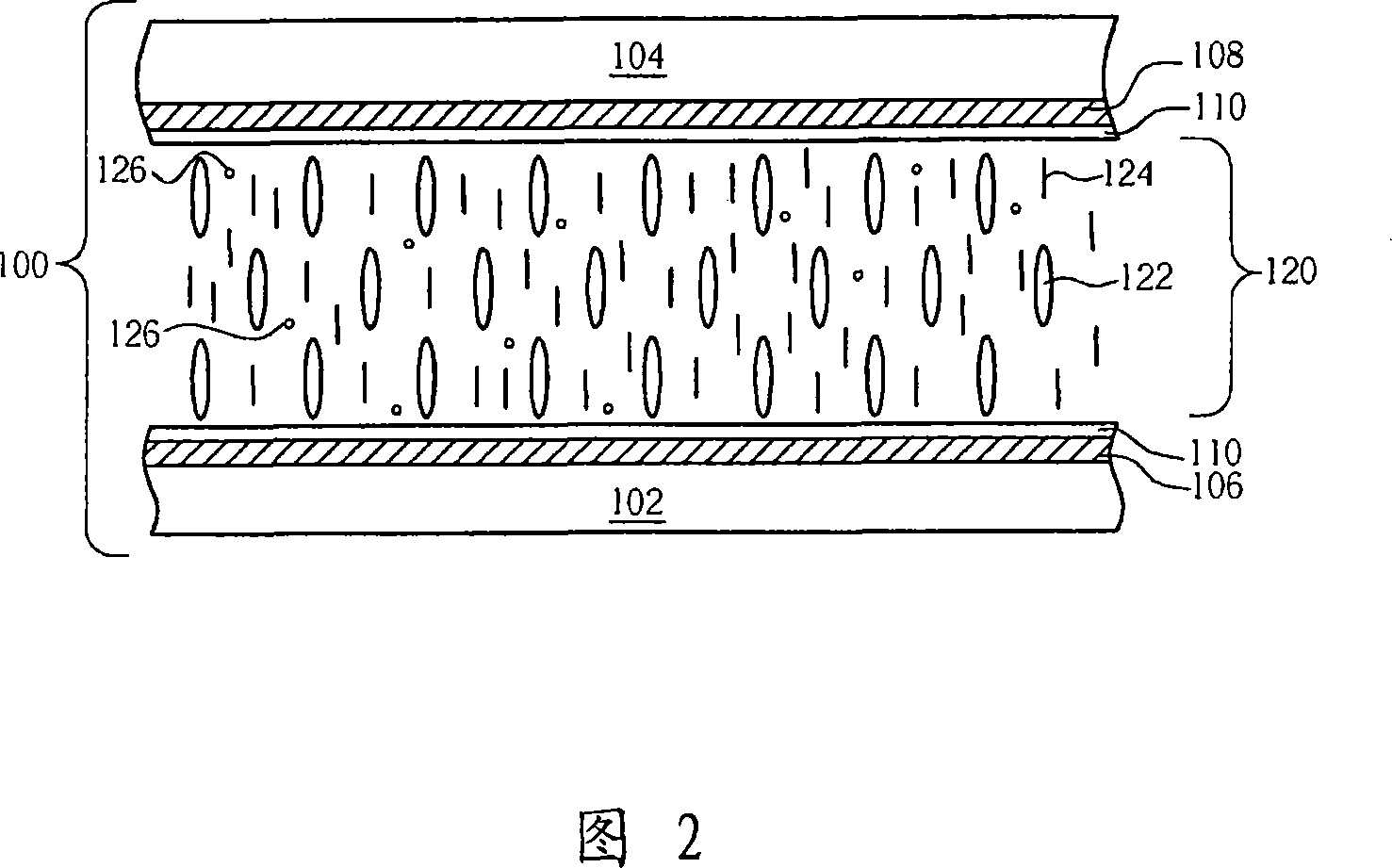

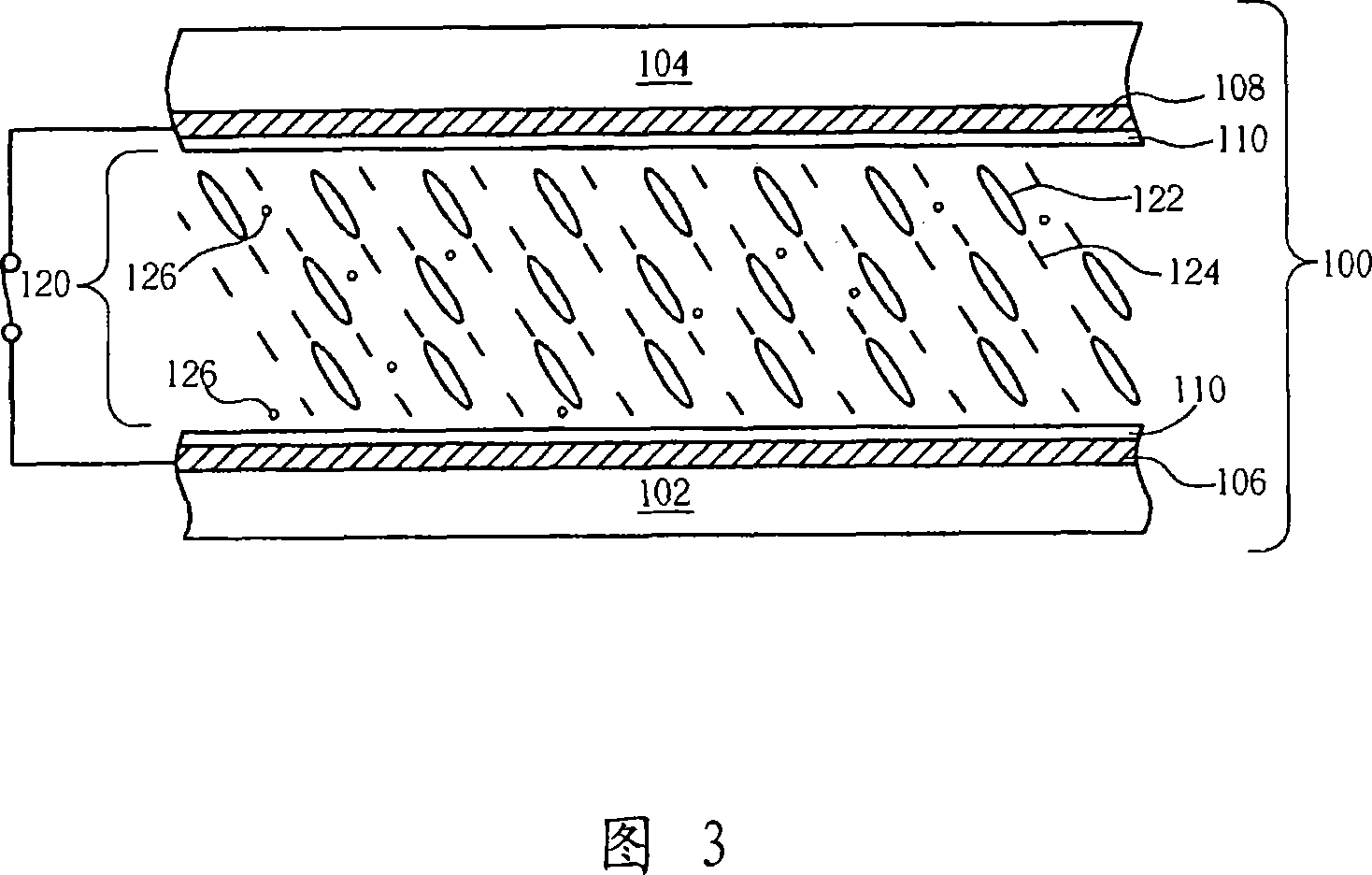

[0021] Please refer to FIG. 1 to FIG. 4 . FIG. 1 to FIG. 4 are schematic diagrams of a method for manufacturing a liquid crystal display panel 100 according to the present invention, wherein the liquid crystal display panel 100 may be a multi-domain vertical alignment liquid crystal display panel. As shown in FIG. 1 and FIG. 2 , first, a lower substrate 102 and an upper substrate 104 are provided, and the opposite surfaces of the lower substrate 102 and the upper substrate 104 respectively include conductive layers 106, 108, wherein the conductive layers 106, 108 can be respectively pixel electrodes and The common electrode, or both are common electrodes, and the surfaces of the conductive layers 106 and 108 can be selectively provided with an alignment film 110 , such as a vertical alignment film made of polyamide (PI). As shown in FIG. 1 , a sealant 130 is formed on the surrounding non-display area of the lower substrate 102 relative to the surface of the upper substrate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com