Method of synthesizing axungia alkyl dimethyl group amine oxide

A technology of aliphatic alkyl dimethyl amine oxide and aliphatic alkyl dimethyl tertiary amine is applied in the field of synthesizing amphoteric surfactants in organic chemistry, and achieves the advantages of improving product yield, reducing energy consumption and improving charging coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 2130kg dodecyldimethyl tertiary amine, a certain amount of deionized water, 21.3kg citric acid, 21.3kg ethylenediaminetetraacetic acid disodium salt, 21.3kg tetrabutylammonium bromide catalyst in the jacketed reactor , heated to 55-60°C, and after 15 minutes of stabilization, began to slowly add 1237kg of 27.5% aqueous hydrogen peroxide solution dropwise. Control the dropping speed and turn on the cooling water appropriately to keep the system temperature within the range of 55-65°C. After dripping the aqueous hydrogen peroxide solution, continue the insulation reaction for 2.0 h. Then, the temperature was raised to 75-80° C., and the reaction was kept for 2.0 hours. A light yellow liquid is obtained, which is dodecyl dimethyl amine oxide.

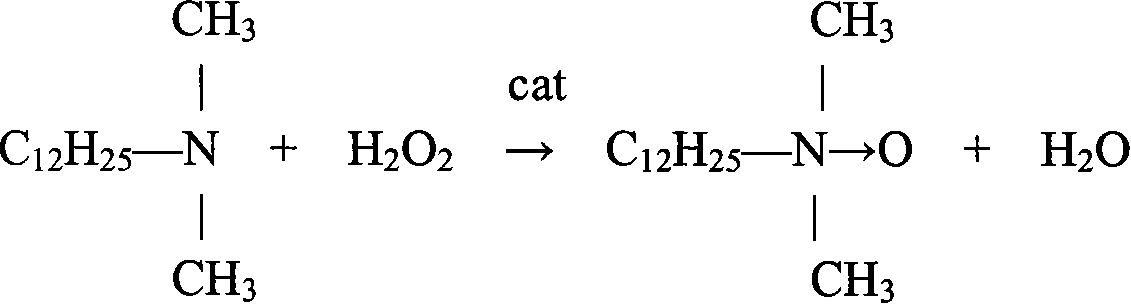

[0020] The reaction equation in the above-mentioned embodiment is:

[0021]

Embodiment 2

[0023] Add 2970kg octadecyldimethyl tertiary amine, a certain amount of deionized water, 148.5kg citric acid, 148.5kg ethylenediaminetetraacetic acid disodium salt, 297kg hexadecyl trimethyl bromide in the jacketed reactor ammonium catalyst, heated to 55-60°C, and after 15 minutes of stabilization, began to slowly add 1020kg of 50% hydrogen peroxide aqueous solution dropwise. Control the dropping speed and turn on the cooling water appropriately to keep the system temperature within the range of 55-65°C. After dripping the aqueous hydrogen peroxide solution, continue the insulation reaction for 2.0 h. Then, the temperature was raised to 75-80° C., and the reaction was kept for 2.0 hours. Finally, 520 kg of sodium bisulfite was added, and the mixture was incubated and stirred for 0.5 hour to obtain a light yellow liquid, which became a white paste after cooling, which was stearyl dimethyl amine oxide.

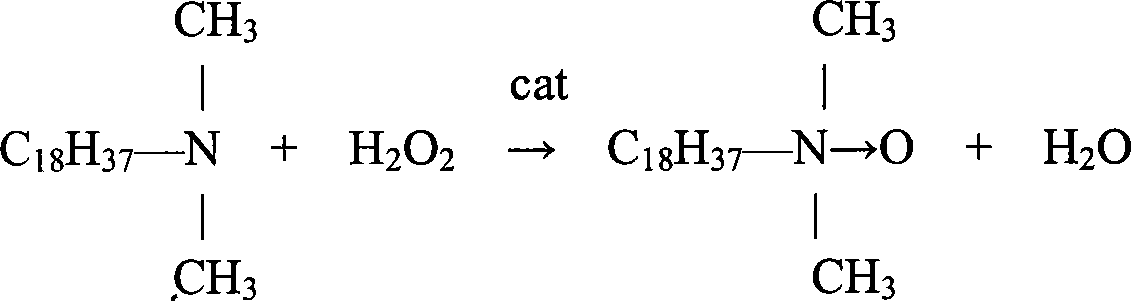

[0024] The reaction equation in the above-mentioned embodiment is:

[00...

Embodiment 3

[0027] Add 2690kg hexadecyldimethyl tertiary amine, a certain amount of deionized water and 95% ethanol, 53.8kg citric acid, 53.8kg ethylenediaminetetraacetic acid disodium salt, 107.6kg tetrabutyl Ammonium bromide catalyst, heated to 55-60 ° C, after 15 minutes of stabilization, began to slowly add 1360 kg of 30% hydrogen peroxide aqueous solution dropwise. Control the dropping speed and turn on the cooling water appropriately to keep the system temperature within the range of 55-65°C. After dripping the aqueous hydrogen peroxide solution, continue the insulation reaction for 2.0 h. Then, the temperature was raised to 75-80° C., and the reaction was kept for 2.0 hours. Finally, 208 kg of sodium bisulfite was added, and the mixture was incubated and stirred for 0.5 hour to obtain a light yellow liquid, namely hexadecyldimethylamine oxide.

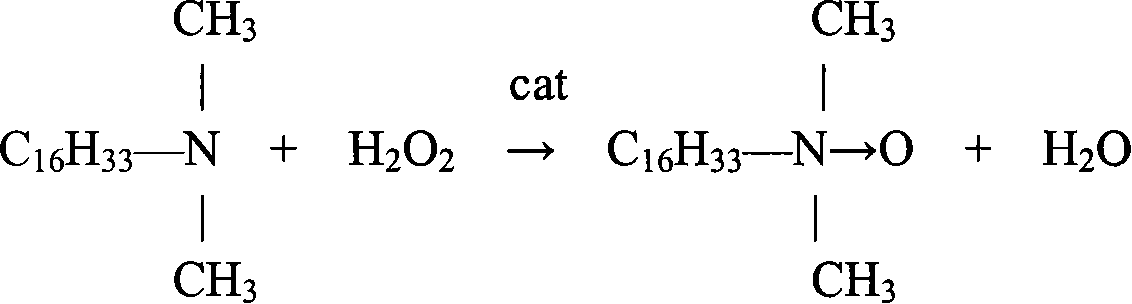

[0028] The reaction equation in the above-mentioned embodiment is:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com