Filler column and gas chromatography and its preparation and organic analysis method

A technology of gas chromatograph and packed column, which is applied in the fields of packing column, gas chromatograph including the packed column and the preparation of the packed column, and the analysis of organic matter in battery electrolyte, which can solve the problems of high cost and large quantitative analysis error , to achieve the effect of large column capacity and reduced error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

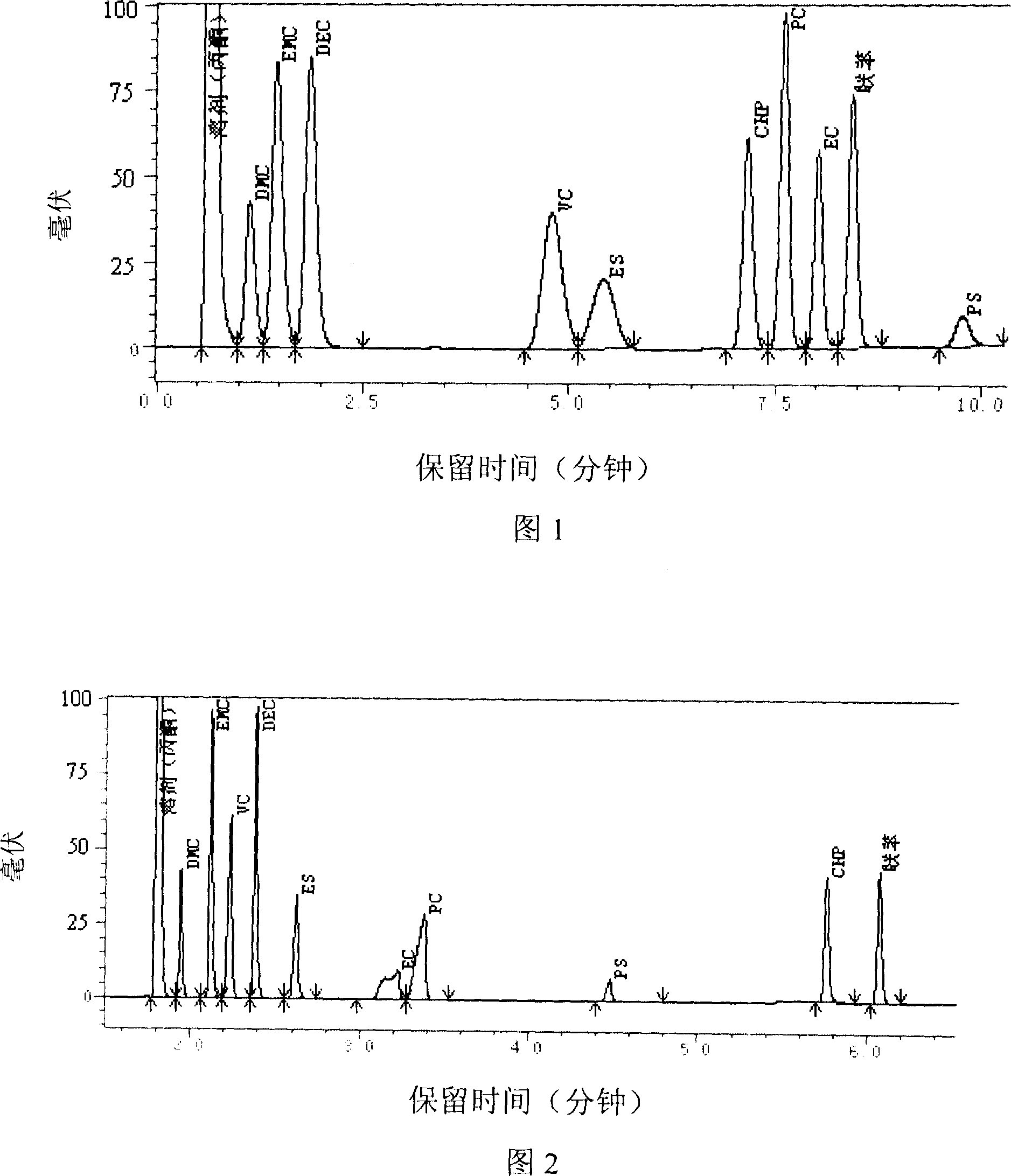

[0034] This example illustrates the effect of using the packed column provided by the invention to analyze organic matter in battery electrolyte.

[0035] (1) Clean the glass tube

[0036] Cut out a hollow glass tube of 1 m × 3 mm (inner diameter), soak it in chromic acid lotion for 12 hours, wash the glass tube with water, ethanol, and acetone in sequence, and dry it in an oven at 100°C for later use.

[0037] (2) Preparation of mixed stationary phase

[0038] In a fume hood, take 1 gram of polyethylene glycol-20000 and dissolve it in about 50 ml of propanol, then mix it with 9 grams of 80-100 mesh 101 acid-washed silanized white support, evaporate acetone in a water bath at 60 ° C, and then infra-red Thoroughly dry under the lamp to obtain stationary phase A.

[0039] In a fume hood, take 1 gram of phenylmethylpolysiloxane with 50% phenyl group content and dissolve it in about 50 ml of propanol, and then mix it evenly with 9 grams of 80-100 mesh 101 acid-washed silanized w...

Embodiment 2

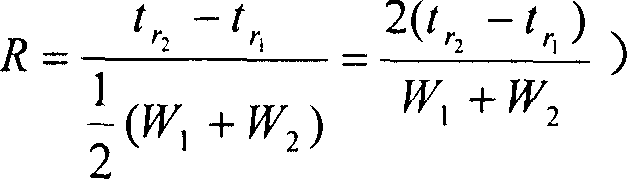

[0062] Prepare and use the packed column according to the method of Example 1, the difference is: the hollow tube is a stainless steel tube of 1.5 meters × 4 mm (inner diameter), soaked for 12 hours with 10% sodium hydroxide, and then sequentially Wash the stainless steel tube with water, ethanol, and acetone, and dry it in an oven at 100°C; the mixed stationary phase uses 60-80 mesh 88 acid-washed silanized white support; the mixed stationary phase includes 15 grams of stationary phase A and 5 grams of stationary phase Phase B; And test the same sample as Example 1 under the following chromatographic conditions:

[0063] Vaporization chamber temperature: 270°C

[0064] Detector (FID): 270°C, air: hydrogen = 10:1;

[0065] Column temperature: The column temperature rise program starts from 80°C at 15°C / min to 100°C, then at 40°C / min to 130°C, and then keeps warm for 3 minutes, then at 40°C / min to 200°C, and then at 25°C ℃ / min rises to 230℃ and keeps warm for 3 minutes;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com