Method for preparing single nano material in pore space structure

A technology of nanomaterials and holes, which is applied in the field of preparation of single nanomaterials, can solve the problems of expensive electron beam exposure process system and high process cost, and achieve the effect of controllable position, simple process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

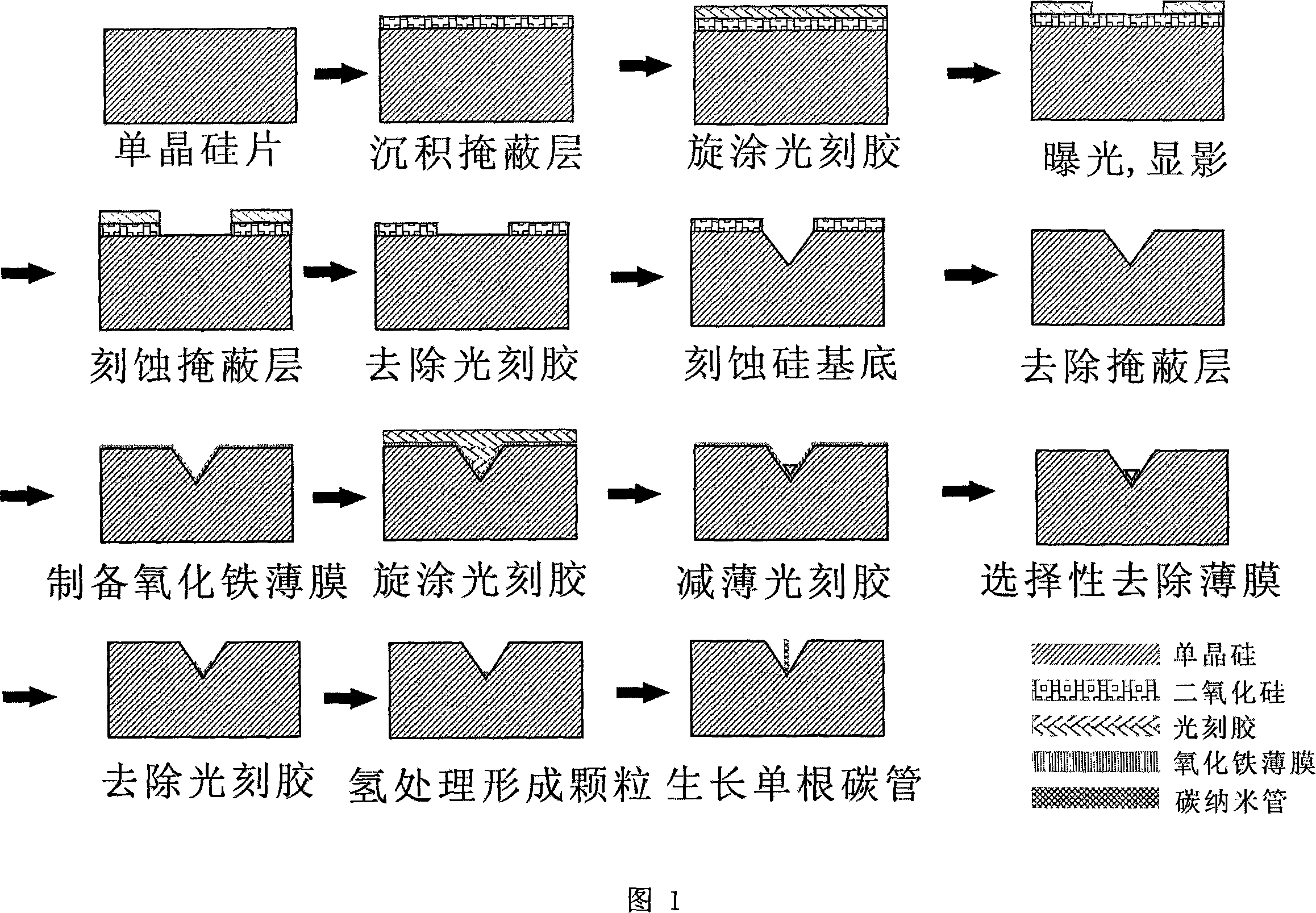

[0014] The present invention is a method of fabricating a single nanomaterial in a porous structure comprising the following sequential steps:

[0015] (a) Etch a hole structure on the substrate: first deposit a layer of masking layer on the substrate, then spin-coat a layer of photoresist, and use photolithography technology to open holes on the photoresist; The masking layer in the hole protected by the photoresist exposes the surface of the substrate, and then the photoresist is removed; the substrate material in the hole of the masking layer is etched to form a hole structure on the substrate, and then the masking layer on the surface is removed. The substrate can be metal, semiconductor or insulator, or a multi-layer structure material composed of two or more of the above materials as required. Etching adopts plasma etching or chemical solution etching.

[0016] (b) Depositing a metal or oxide film at the bottom of the hole in the substrate: first deposit a layer of meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com