Method for producing convenient nutritive rice-tea and product

A production method and technology of rice tea, which is applied in the field of preparation of solid rice tea drinks, can solve the problems of not soft taste of drinks and high price of barley, and achieve the effects of low production cost, easy digestion and absorption, and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

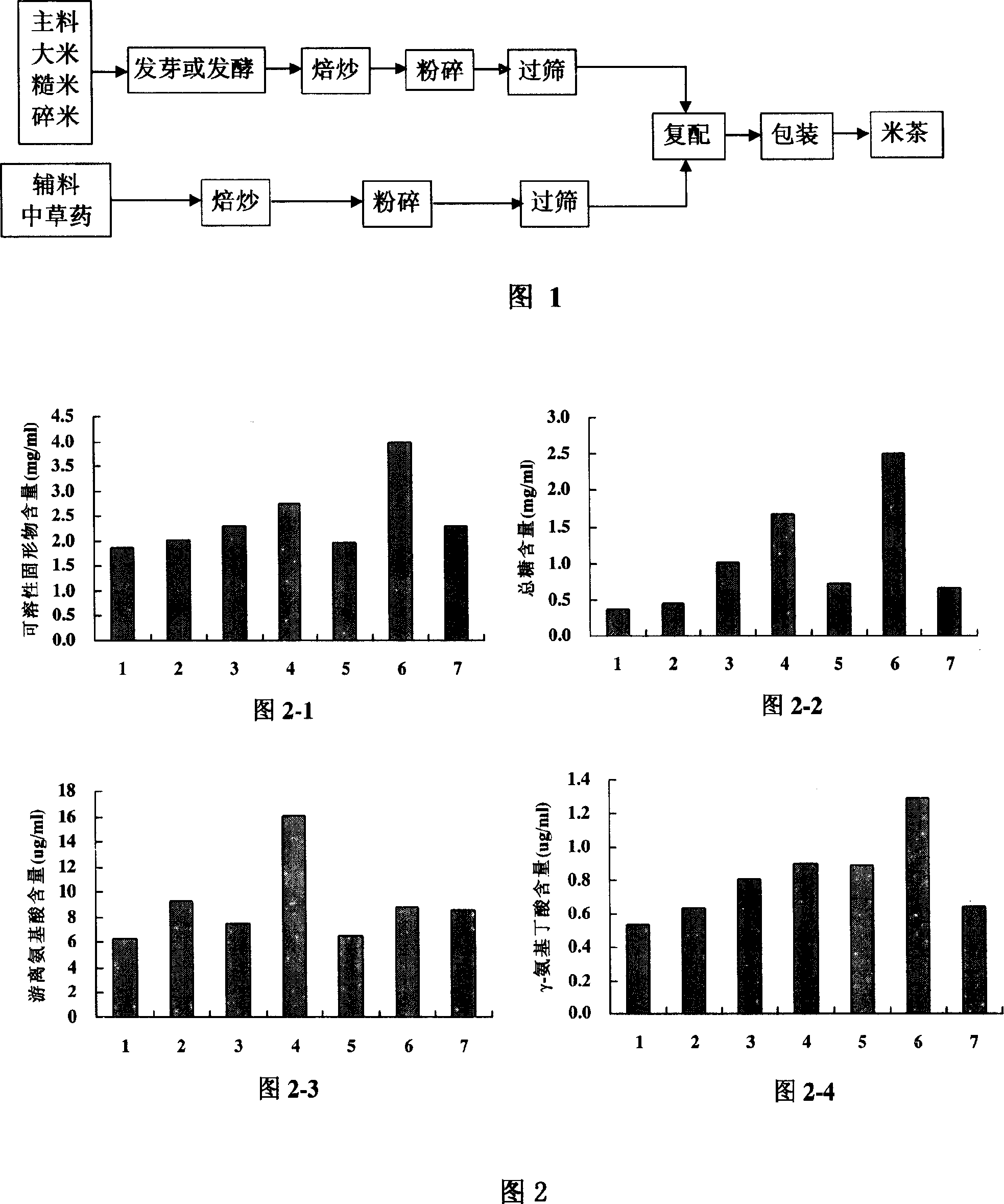

Method used

Image

Examples

Embodiment 1

[0032] Wash 50 kg of rice with tap water, cool and remove the water, and roast at 200°C until the rice noodles are golden yellow and fragrant, cool, and set aside;

[0033] Get above-mentioned material and pulverize, cross 10 mesh sieves, obtain 35 kilograms of rice flour material, set aside;

[0034] Select 1 kg of honeysuckle powder, 1 kg of licorice root, and 1 kg of lotus seed core according to the weight ratio, roast at 150°C respectively, pulverize the auxiliary materials and pass through a 10-mesh analytical sieve to obtain 0.6 kg of honeysuckle powder, 0.7 kg of licorice powder, and 1 kg of lotus seed core. 0.6 kg of core powder, set aside; by weight, get 50 parts of the above-mentioned fried rice, 0.5 part of honeysuckle, 0.5 part of licorice, and 0.5 part of lotus seed core, and mix evenly to obtain instant rice tea.

[0035] Get the instant rice tea, quantitatively weigh 5g, and use the packaging of teabag to be the finished rice tea in bag. In the following example...

Embodiment 2

[0037] Wash 50 kg of rice with tap water, add 50 kg of tap water, soak at 35°C for 10 hours to allow it to ferment naturally, then wash with tap water, cool to remove water, and roast the rice material at 150°C until The rice noodles are fragrant until golden yellow, cooled and set aside;

[0038] Get above-mentioned material and pulverize, cross 10 mesh sieves, obtain 40 kilograms of rice flour material, set aside;

[0039] Select 1 kg of licorice as an auxiliary material according to the weight ratio, roast at 150° C., pulverize the above-mentioned auxiliary materials, and pass through a 10-mesh analytical sieve to obtain 0.55 kg of licorice powder, which is set aside;

[0040] Take 40 parts of fermented rice flour prepared above, 2.0 parts of licorice and 0.1 part of fried rice essence (commercially purchased), and mix evenly to obtain instant rice tea. Produce bagged rice tea by the step of embodiment 1.

Embodiment 3

[0042] Wash 50 kg of broken rice with tap water, add 250 kg of tap water, soak it at 28°C for 20 hours to allow it to ferment naturally, then wash it with tap water, cool it to remove water, and roast the material at 200°C. until golden yellow and fragrant, cool and set aside;

[0043] Get above-mentioned material and pulverize, cross 40 mesh sieves, obtain 40 kilograms of rice flour material, set aside;

[0044] Select 1 kg of lotus honeysuckle as an auxiliary material according to the weight ratio, roast at 200° C., pulverize the auxiliary material, and pass through a 40-mesh analytical sieve to obtain 0.65 kg of honeysuckle powder, which is set aside;

[0045] Take 50 parts of the above-mentioned rice flour material, 2.0 parts of honeysuckle powder and 0.075 parts of fried rice essence, mix well, and prepare rice tea in bags according to the method of Example 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com