Technique for purifying spherosinin by fermenting green muscardine fungus

A technology of swainsonin and metarhizium anisopliae, applied in the field of bioengineering, can solve the problems of lack of swainsonin production, reduced efficiency and loss of swainsonine, and solve the ultimate shortage of grassland locoweed resources, Conducive to the effect of ecological protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

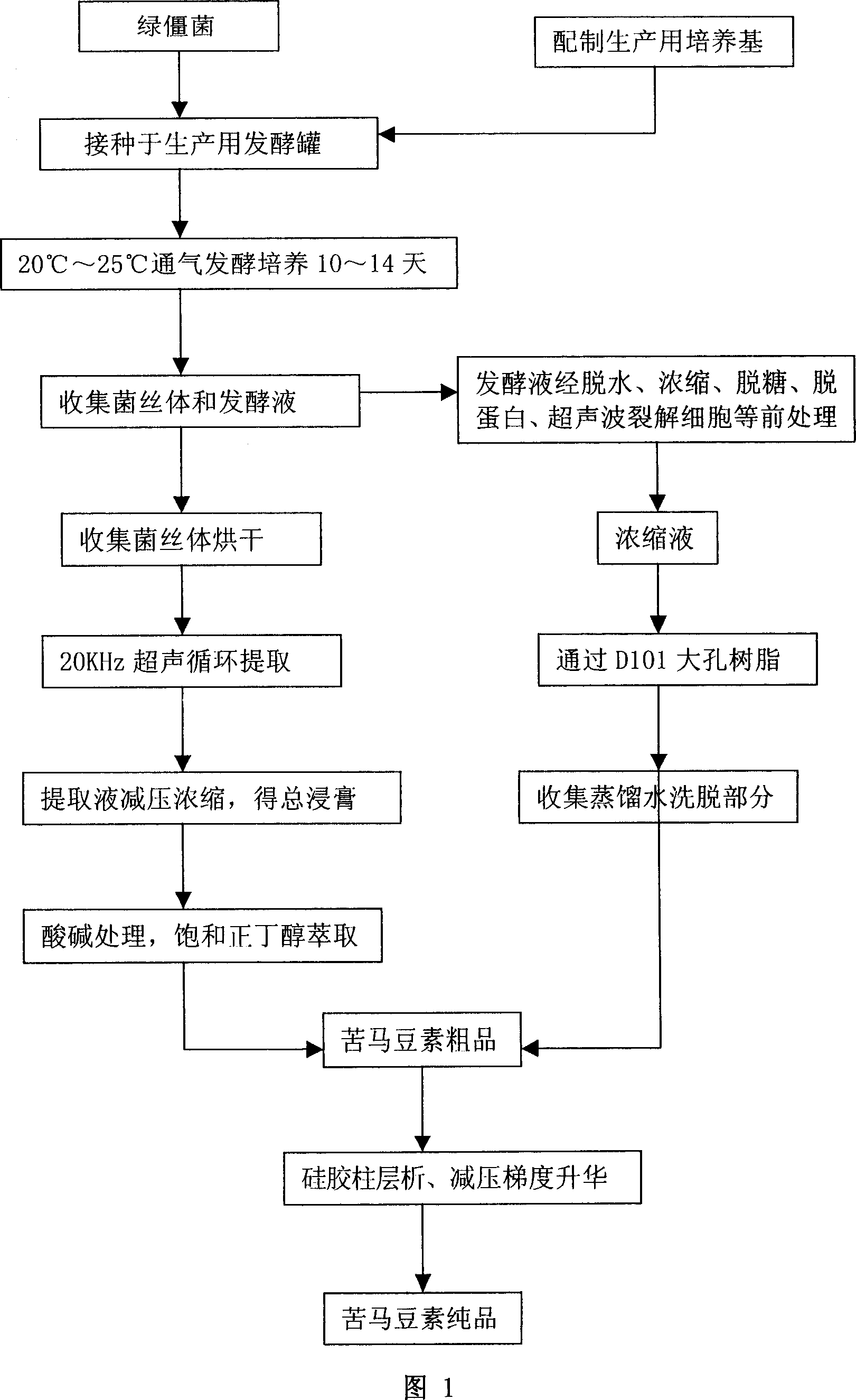

Method used

Image

Examples

Embodiment 1

[0058] 1) Preservation and subculture of Metarhizium anisopliae strains: inoculate Metarhizium anisopliae on Gaoshi Synthetic No. 1 medium, culture for 4 days, and store them in a -20°C low-temperature refrigerator after the strains have fully grown and developed. Passed down once a month.

[0059] The formula of described Gao's synthetic No. 1 medium consists of potassium nitrate 1g, magnesium sulfate 0.5g, ferrous sulfate 0.01g, dipotassium hydrogen phosphate 0.5g, sodium chloride 0.5g, soluble starch 20g, agar 20g, water 1000ml.

[0060] 2) Metarhizium anisopliae was inoculated in 2L biofermentation modified Klebsonian synthetic medium No. 1 in a sterile state, cultured with aeration at 25° C. for 14 days, 125 g of mycelia and 2 L of culture solution were collected, dried, and set aside.

[0061] The formula of described improved Kjeldahl synthetic No. 1 medium consists of: soluble starch 10g, dextrin 10g, potassium nitrate 2g, dipotassium hydrogen phosphate 2g, sodium chl...

Embodiment 2

[0071] 1) Preservation and subculture of Metarhizium anisopliae strains: inoculate Metarhizium anisopliae on Gaoshi Synthetic No. 1 medium, culture for 5 days, and after the strains have fully grown and developed, store them in a -20°C low-temperature refrigerator, every 45 days Passage once;

[0072] The formula of described Gao's synthetic No. 1 medium consists of potassium nitrate 1g, magnesium sulfate 0.5g, ferrous sulfate 0.01g, dipotassium hydrogen phosphate 0.5g, sodium chloride 0.5g, soluble starch 20g, agar 20g, water 1000ml;

[0073] 2) Under sterile conditions, Metarhizium anisopliae was inoculated in 5 L of modified Kjeldahl Synthetic Medium No. 1 for biological fermentation, cultured with aeration at 23° C. for 12 days, 312 g of mycelium and 5 L of culture solution were collected, dried, and set aside.

[0074] The formula of described improved Kjeldahl synthetic No. 1 medium consists of: soluble starch 10g, dextrin 10g, potassium nitrate 2g, dipotassium hydrogen...

Embodiment 3

[0084] 1) Preservation and subculture of Metarhizium anisopliae strains: inoculate Metarhizium anisopliae on Gao’s Synthetic No. 1 medium and culture for 6 days. After the strains have fully grown and developed, store them in a low-temperature refrigerator at -20°C, and store them in a low-temperature refrigerator every 60 days. Passage once;

[0085] The formula of described Gao's synthetic No. 1 medium consists of potassium nitrate 1g, magnesium sulfate 0.5g, ferrous sulfate 0.01g, dipotassium hydrogen phosphate 0.5g, sodium chloride 0.5g, soluble starch 20g, agar 20g, water 1000ml;

[0086] 2) Metarhizium anisopliae was inoculated in 10 L of modified Kjeldahl Synthetic Medium No. 1 for biological fermentation in a sterile state, cultured with aeration at 20° C. for 10 days, 625 g of mycelium and 10 L of culture solution were collected, dried, and set aside.

[0087] The formula of described improved Kjeldahl synthetic No. 1 medium consists of: soluble starch 10g, dextrin 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com