High ORAC value oligomeric proanthocyanidin and purifying method for the same

A technology of oligomeric proanthocyanidins and proanthocyanidins, which is applied in the direction of pharmaceutical formulations, plant raw materials, medical preparations containing active ingredients, etc., can solve the problems of low yield of oligomeric proanthocyanidins, small sample loading, and low membrane flux, etc., and achieve Increased membrane flux and sample loading, shortened ultrafiltration time, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

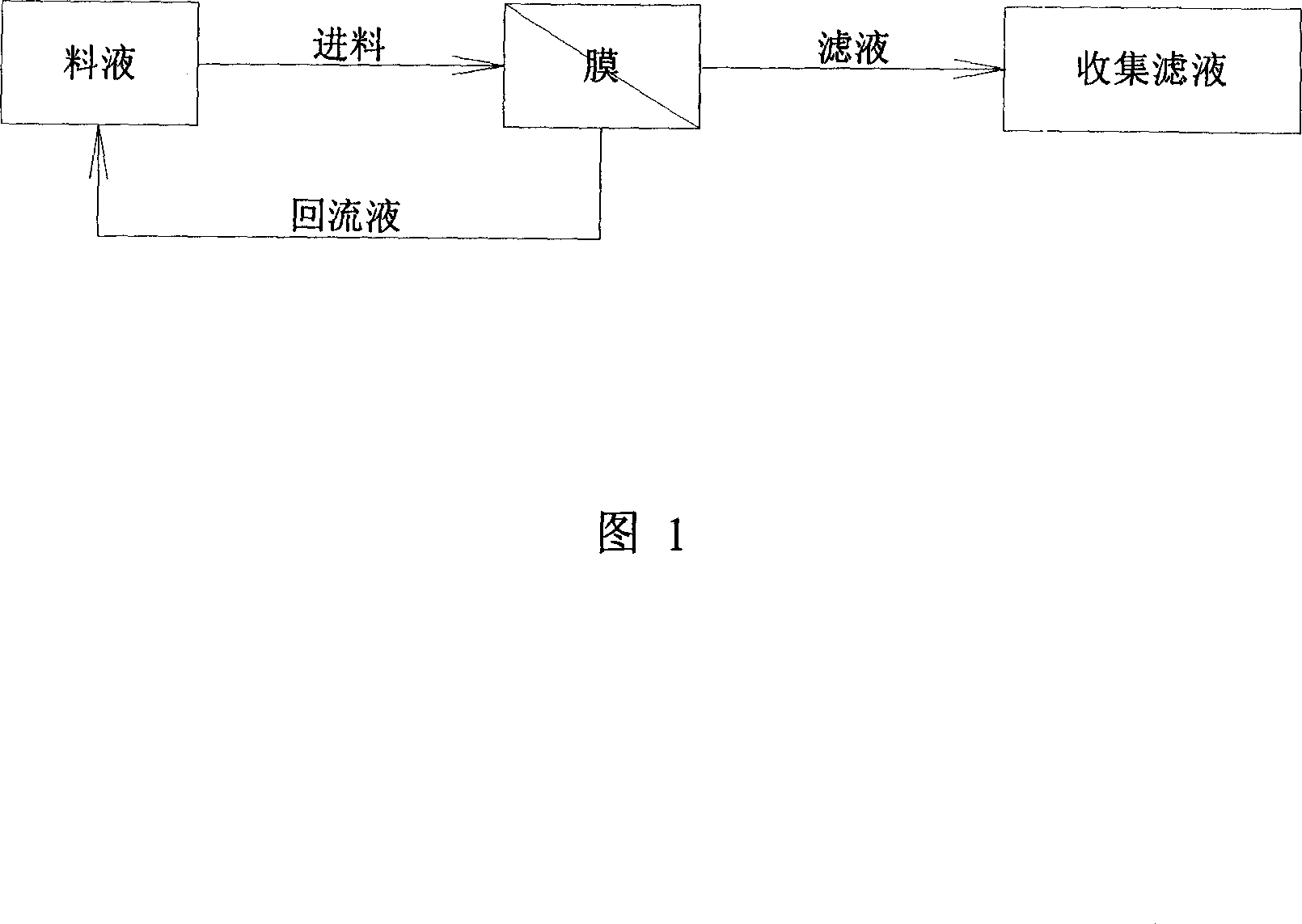

Method used

Image

Examples

Embodiment 1

[0055] 1. The purification of proanthocyanidins rough purification product

[0056] 1. After crushing the grape seeds, use 55% ethanol to carry out dynamic circulation extraction in a multifunctional ethanol extraction tank to obtain an extraction concentrate;

[0057] 2. Extract the concentrated solution and add 6 times the volume of water, stir and mix well, then sink in water for 16 hours;

[0058] 3. Filtrate and separate the above-mentioned water sinking liquid to obtain a clear filtrate;

[0059] 4. Adsorb the filtrate to the HPD400A macroporous adsorption resin column, so that the active ingredients in the filtrate are adsorbed by the resin. The loading was 0.625 grams of filtrate of the feedstock per gram of dry resin.

[0060] 5. Wash the resin with 3-4 column volumes of deionized water at a flow rate of 3-4 column volumes / hour;

[0061] 6. Using 50% ethanol to desorb the active ingredient adsorbed by the resin to obtain a desorption liquid. The flow rate of the e...

Embodiment 2

[0070] 1. The purification of proanthocyanidins rough purification product

[0071] Same as Example 1

[0072] 2. Purification of oligomeric proanthocyanidins with high ORAC value by membrane ultrafiltration

[0073] 1. Weigh 10kg of the crudely purified proanthocyanidin product above, fully stir and dissolve it with 200L 70°C reverse osmosis water, pass the solution through a 100-mesh sieve, and add it to the feed liquid tank of the organic membrane flat-panel ultrafiltration device;

[0074] 2 Use a flat organic membrane with a relative molecular weight cut-off of 1 million (membrane model JK S-172) for continuous ultrafiltration. During ultrafiltration, the temperature of the material is controlled at about 40°C, and the return valve is adjusted to control the pressure of the feed liquid inlet to 8.0bar. , the outlet pressure was 7.0 bar, and the filtrate was collected, concentrated by reverse osmosis, and spray-dried to obtain 2520 grams of oligomeric proanthocyanidins wi...

Embodiment 3

[0077] 1. The purification of proanthocyanidins rough purification product

[0078] 1. After crushing the pine bark, use 55% ethanol to carry out dynamic circulation extraction in a multifunctional ethanol extraction tank to obtain an extraction concentrate;

[0079] 2. Extract the concentrated solution and add 6 times the volume of water, stir and mix well, then sink in water for 16 hours;

[0080] 3. Filtrate and separate the above-mentioned water sinking liquid to obtain a clear filtrate;

[0081] 4. Adsorb the filtrate to the HPD400A macroporous adsorption resin column, so that the active ingredients in the filtrate are adsorbed by the resin. 0.625 grams of filtrate of starting material per gram of dry resin.

[0082] 5. Wash the resin with 3-4 column volumes of deionized water at a flow rate of 3-4 column volumes / hour;

[0083] 6. Using 50% ethanol to desorb the active ingredient adsorbed by the resin to obtain a desorption solution. The flow rate of the ethanol solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com