Method for modifying surface of aluminum electrode foil

An aluminum electrode foil and surfactant technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of destroying electrostatic balance and increasing hydrophilicity, and achieve the effects of good adhesion, improved coverage and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

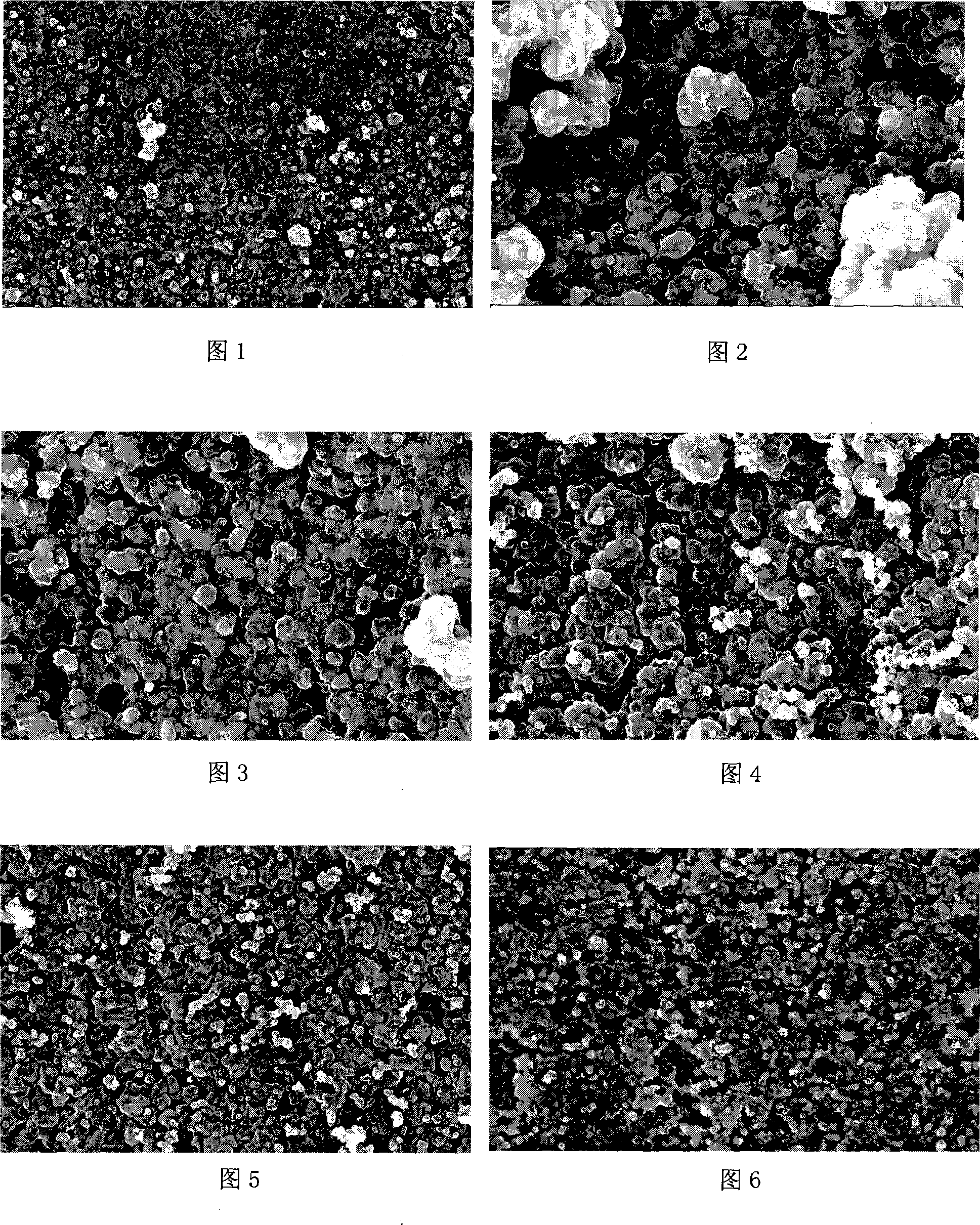

[0030] The aluminum electrode foil with a size of 0.5cm×4.5cm was ultrasonically cleaned with acetone for 5 minutes, dried at room temperature, immersed in a solution of γ-aminopropyltriethoxysilane with a mass fraction of 100%, and surface modified at room temperature for 10 minutes. Rinse first with deionized water and then with ethanol solution, and dry. At -15°C, immerse in a polymerization solution containing a molar ratio of pyrrole: ammonium persulfate: sodium dodecylbenzenesulfonate: p-nitrophenol for 4 hours, and then use deionized Wash with water and absolute ethanol, dry; repeat the step of impregnating the aluminum electrode foil with the polymerization reaction solution twice, and obtain the SEM photo of the aluminum electrode foil coated with a conductive polypyrrole film on the surface, as shown in Figure 1.

Embodiment 2

[0032] Clean the aluminum electrode foil with a size of 0.5cm×4.5cm ultrasonically with methanol for 5 minutes, dry it at room temperature, and then immerse it in a solution of vinyltrioxysilane with a mass fraction of 100%, and perform surface modification treatment at room temperature for 120 minutes. Rinse with water and then with ethanol solution, and dry. At -15°C, immerse in a polymerization solution containing a molar ratio of pyrrole: ammonium persulfate: sodium dodecylbenzenesulfonate: p-nitrophenol at 1:0.20:0.04:0.08 for 4 hours, and then use deionized Wash with water and absolute ethanol, and dry. The SEM photo of the aluminum electrode foil coated with a conductive polypyrrole film is shown in FIG. 2 .

Embodiment 3

[0034] The aluminum electrode foil with a size of 0.5cm×4.5cm was ultrasonically cleaned with ethanol for 5min, dried at room temperature, immersed in a solution of 0.5% γ-aminopropyltriethoxysilane in mass fraction, and surface modified at room temperature for 120min. Rinse with deionized water and ethanol solution, and dry. At -15°C, immerse in a polymerization solution containing a molar ratio of pyrrole: ammonium persulfate: sodium dodecylbenzenesulfonate: p-nitrophenol 1: 0.25: 0.04: 0.10 for 4 hours, and then use deionized Wash with water and absolute ethanol, and dry. The SEM photo of the aluminum electrode foil coated with a conductive polypyrrole film is shown in Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com