Integral gradient self-lubricating bearing, and fabricating method

A self-lubricating bearing and solid lubrication technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of metal bushings requiring drilling, unfavorable environmental protection, complex manufacturing processes, etc., to achieve service life and overall mechanical properties. Improve, relieve thermal stress, enhance the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

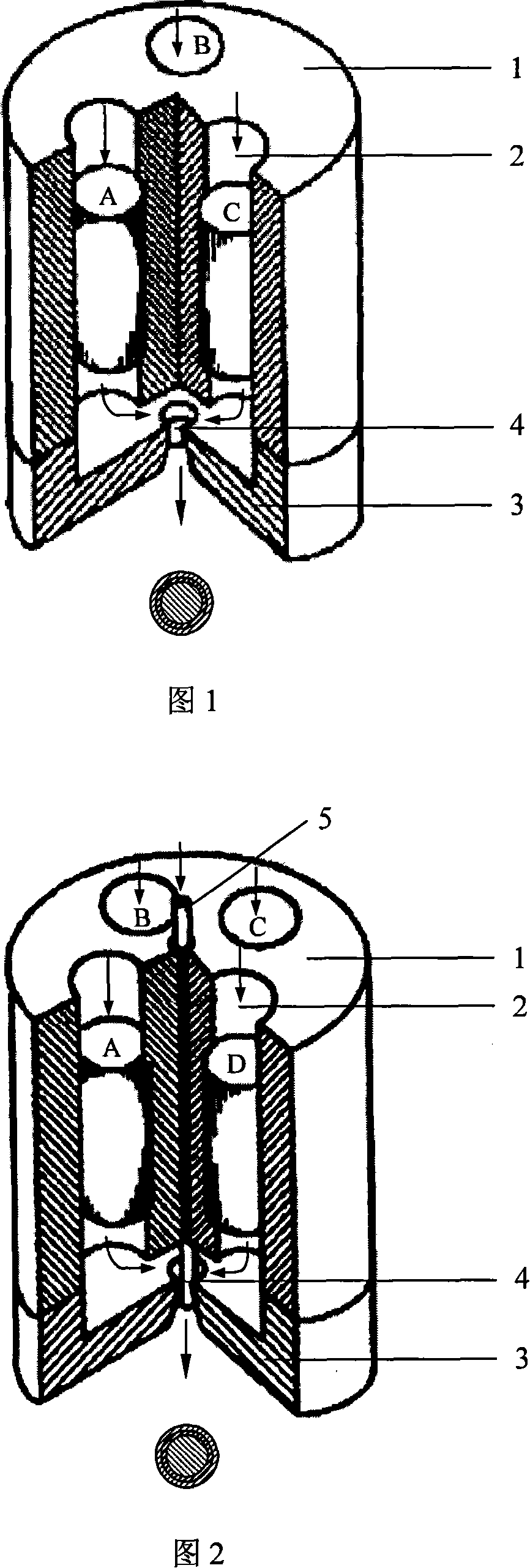

Image

Examples

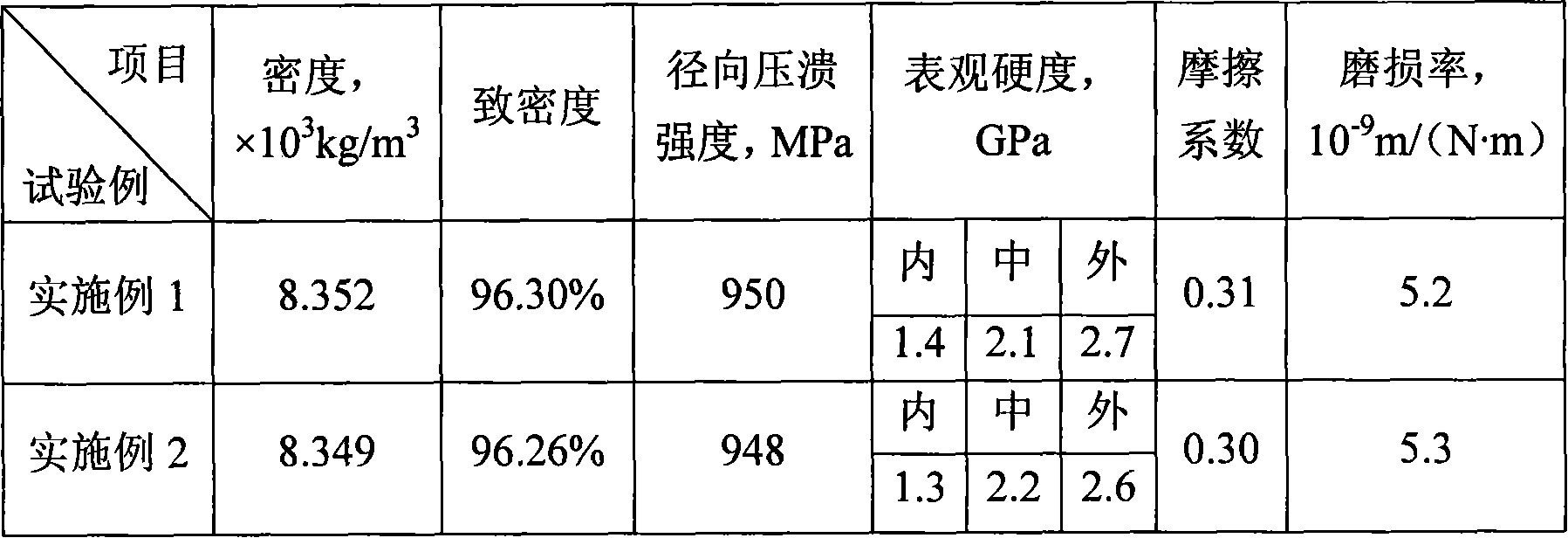

Embodiment 1

[0035] The material ratio is expressed in volume percentage: 100% stainless steel in the pressure bearing layer; 10% molybdenum disulfide and 90% tin bronze in the solid lubricating layer; 8% molybdenum disulfide, 60% tin bronze and 32% stainless steel in the transition layer. The particle size of the molybdenum disulfide powder is 3-5 μm, the particle size of the tin bronze powder is 30-40 μm, and the particle size of the stainless steel powder is 8-12 μm. After the powders of each layer are uniformly mixed in proportion, a binder (95wt% of the mixed powder and 5wt% of the binder) is added. The binder is composed of HPMC (content 10wt%) and deionized water (content 90wt%). After mixing into a powder viscous body, seal and wrap it with a plastic wrap, and store it at room temperature for 10 to 24 hours. The powder viscous body is made into a pre-extruded billet according to the size of the extrusion cylinder. Put the pre-extruded blanks of each layer into the extrusion barre...

Embodiment 2

[0037] The material ratio is expressed in volume percentage: 100% stainless steel in the bearing layer; 15% molybdenum disulfide and 85% tin bronze in the solid lubricating layer; 6% molybdenum disulfide, 54% tin bronze and 40% stainless steel in the transition layer. The particle size of the molybdenum disulfide powder is 3-5 μm, the particle size of the tin bronze powder is 30-40 μm, and the particle size of the stainless steel powder is 8-12 μm; the pressure-bearing layer is directly made of stainless steel rods. After the powders of the solid lubricating layer and the transition layer are uniformly mixed in proportion, a binder (97wt% of the mixed powder and 3wt% of the binder) is added. The binder is composed of HPMC (content 8wt%) and deionized water (content 92wt%). After being mixed into a powder viscous body, it is sealed and wrapped with a plastic wrap, stored at room temperature for 10-32 hours, and the powder viscous body is made into a pre-extruded billet accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com