Method for drilling refractory materials in thermal state, and drilling equipment in thermal state

A drilling device and refractory material technology, applied in the field of hot drilling devices, can solve problems such as disrupting the process, high risk, and harshness, and achieve the effect of enriching adjustment methods and expanding the amount of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] For the convenience of describing the present invention, the thermal drilling device and the drilling method are combined for description below, so that the description logic is more reasonable, and at the same time, in order to save space.

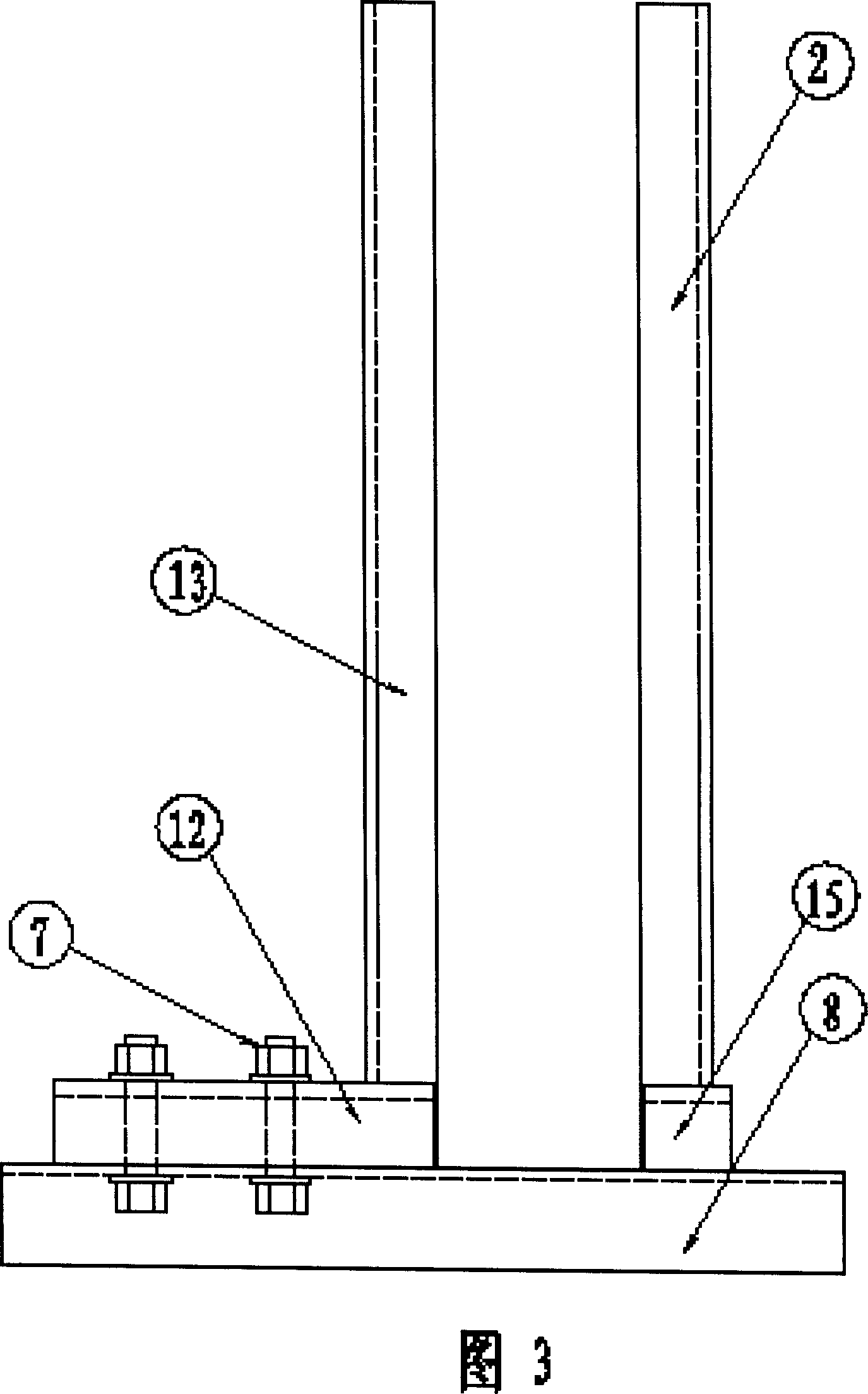

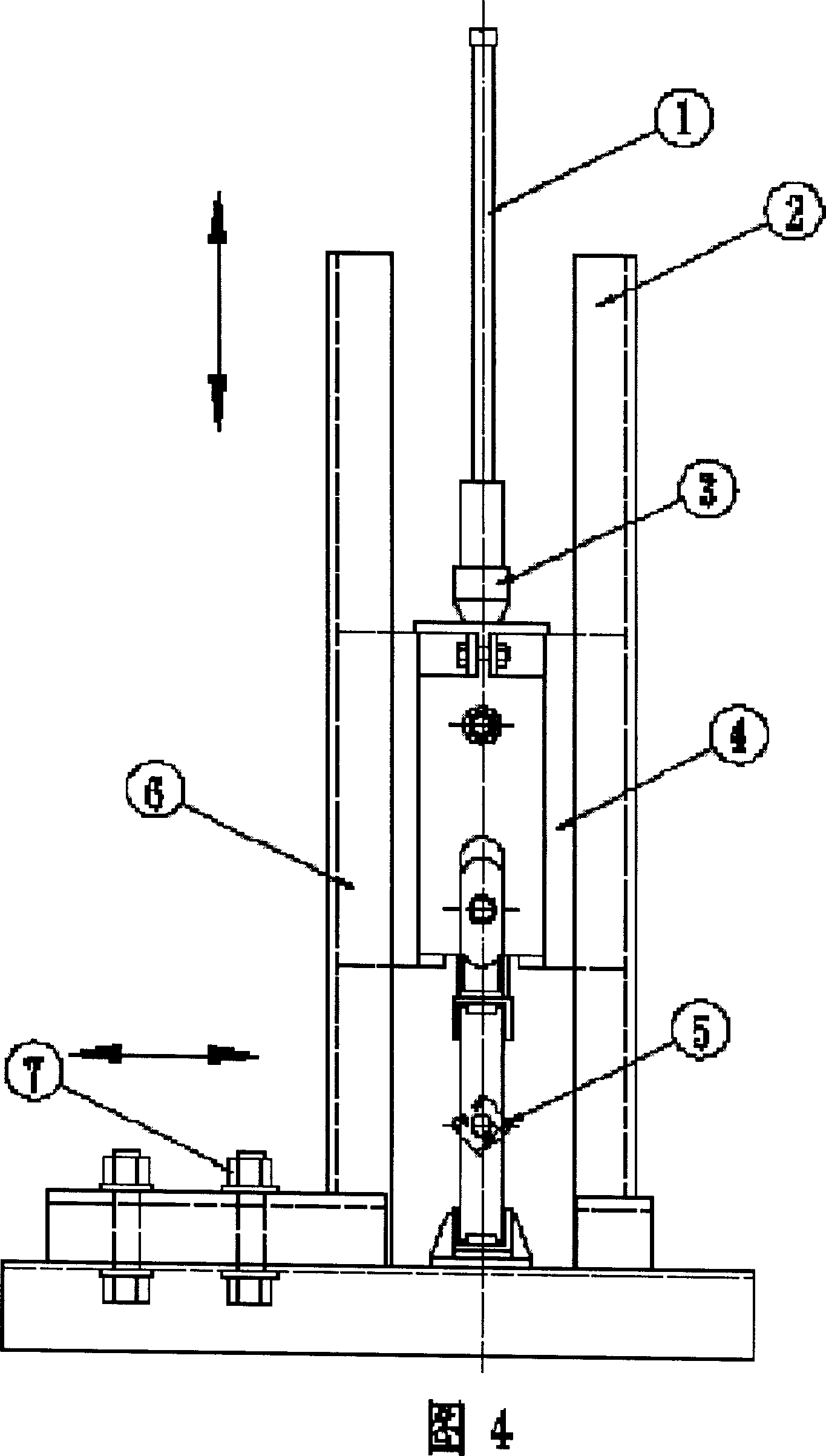

[0020] As shown in FIG. 4, the thermal drilling device includes a guiding and clamping track device. The guiding and clamping track device includes a base plate ⑧, on which a movable guide rail ⑥ and a fixed guide rail ② that can slide horizontally are installed on the base plate ⑧, and the inner surface of the movable guide rail ⑥ and the fixed guide rail ② in the vertical direction forms a guide rail surface. As shown in Figures 2 and 3, the moving guide rail ⑥ is composed of a horizontal part and a vertical part . The vertical part is welded to the inner end of the horizontal part . The horizontal part has a long adjustment hole through which the adjustment bolt ⑦ passes. The horizontal part and the bottom plate ⑧ fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com