Evaporation method of nmmo

A technology of one-effect evaporation and two-effect evaporation, which is applied in the direction of organic chemistry, can solve problems such as affecting material supply, reducing stability, affecting continuous production of the system, etc., to achieve the effect of ensuring continuous operation and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

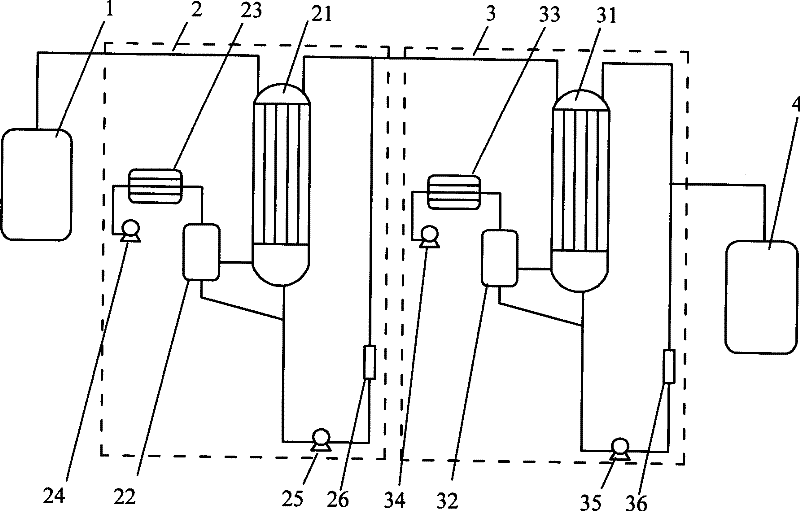

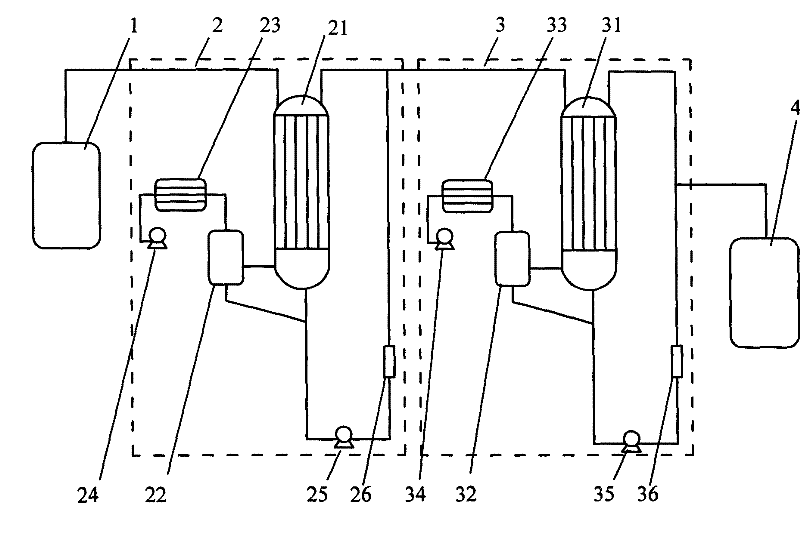

Image

Examples

Embodiment 1

[0037] The NMMO solution concentration of the first-effect feed is 10%, the heating steam temperature is 102°C, the first-effect evaporation temperature is 57°C, the first-effect vacuum degree is 14KPa, the cooling water temperature is 20°C, and the first-effect discharge set concentration is 52%. The second-effect evaporation temperature is 91°C, the second-effect vacuum degree is 7KPa, the chilled water temperature is -3°C, the holding water temperature is 92°C, and the second-effect output concentration is 80%.

Embodiment 2

[0039] The NMMO solution concentration of the first-effect feed is 17%, the heating steam temperature is 102°C, the first-effect evaporation temperature is 59°C, the first-effect vacuum degree is 13KPa, the cooling water temperature is 25°C, and the first-effect discharge set concentration is 56%. The second-effect evaporation temperature is 88°C, the second-effect vacuum degree is 5KPa, the chilled water temperature is -2°C, the holding water temperature is 93°C, and the second-effect output concentration is 82%.

Embodiment 3

[0041] The NMMO solution concentration of the first-effect feed is 24%, the heating steam temperature is 101°C, the first-effect evaporation temperature is 52°C, the first-effect vacuum degree is 11KPa, the cooling water temperature is 28°C, and the first-effect discharge set concentration is 63%. The second-effect evaporation temperature is 90°C, the second-effect vacuum is 3KPa, the chilled water temperature is -4°C, the holding water temperature is 95°C, and the second-effect output concentration is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com