Window material for display

A display and window material technology, applied in the field of display window material, can solve the problems of lack of chemical resistance, insufficient scratch resistance, difficulty in hard coating with high hardness, etc., and achieves good transparency, excellent strength, and surface resistance. Excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] (Manufacturing method of window material for display)

[0063] When the window material for a display of the present invention contains at least two layers of the above-mentioned polyester biaxially stretched sheet or other resin layers, it contains at least two layers of the above-mentioned polyester biaxially stretched sheet and the above-mentioned other resin layers such as the polycarbonate sheet. , after bonding the above-mentioned interlayers using the above-mentioned adhesive or the like, it is processed into a desired shape as a window material for a display. Various known methods can be used for the processing method, but the cutting method using press processing is particularly preferable because it is the lowest cost and can be formed in large quantities.

[0064] (use)

[0065] The display window material of the present invention can be used as a liquid crystal display device (LCD), a cathode ray tube display device (CRT), an EL display device, a plasma dis...

Embodiment 1

[0085] Terephthalic acid and ethylene glycol were polycondensed to obtain polyethylene terephthalate pellets with an intrinsic viscosity of 0.65 dl / g. After drying, it was put into an extruder, melt-extruded at 285° C., extruded from a T-shaped nozzle into a sheet, and cooled to 70° C. with a cooling roll to obtain a sheet with a thickness of 3400 μm. Then, it was introduced into a tenter for transverse stretching, and after preheating in an atmosphere of 125° C. for 10 seconds, it was stretched to 1.4 times in the transverse direction at a stretching speed of 480% / min. Furthermore, without cooling, the sheet was stretched 2.7 times in the transverse direction at a stretching rate of 1300% / min in an atmosphere of 95° C. to obtain a sheet stretched twice in the transverse direction.

[0086] The obtained sheet was preheated with a roll at 85° C. and heated by infrared rays to maintain the temperature of the sheet at 125° C. while stretching 4.8 times in the longitudinal directi...

Embodiment 2

[0090] Polycarbonate (molecular weight: 27,000, caliber 300-4 manufactured by Sumitomo Dow Co., Ltd.) was melt-extruded at 280°C using a melt extruder equipped with a T-die to obtain unstretched polycarbonate with a thickness of 380 μm. Sheet.

[0091] Polyurethane-based thermal adhesives were coated on both sides of the obtained unstretched polycarbonate sheet, and two sheets of polyethylene terephthalate prepared in Example 1 with a thickness of 188 μm were bonded to one of the coated surfaces. An alcohol ester biaxially stretched sheet was bonded to the other side of this polyethylene terephthalate biaxially stretched sheet to obtain a window material for a display.

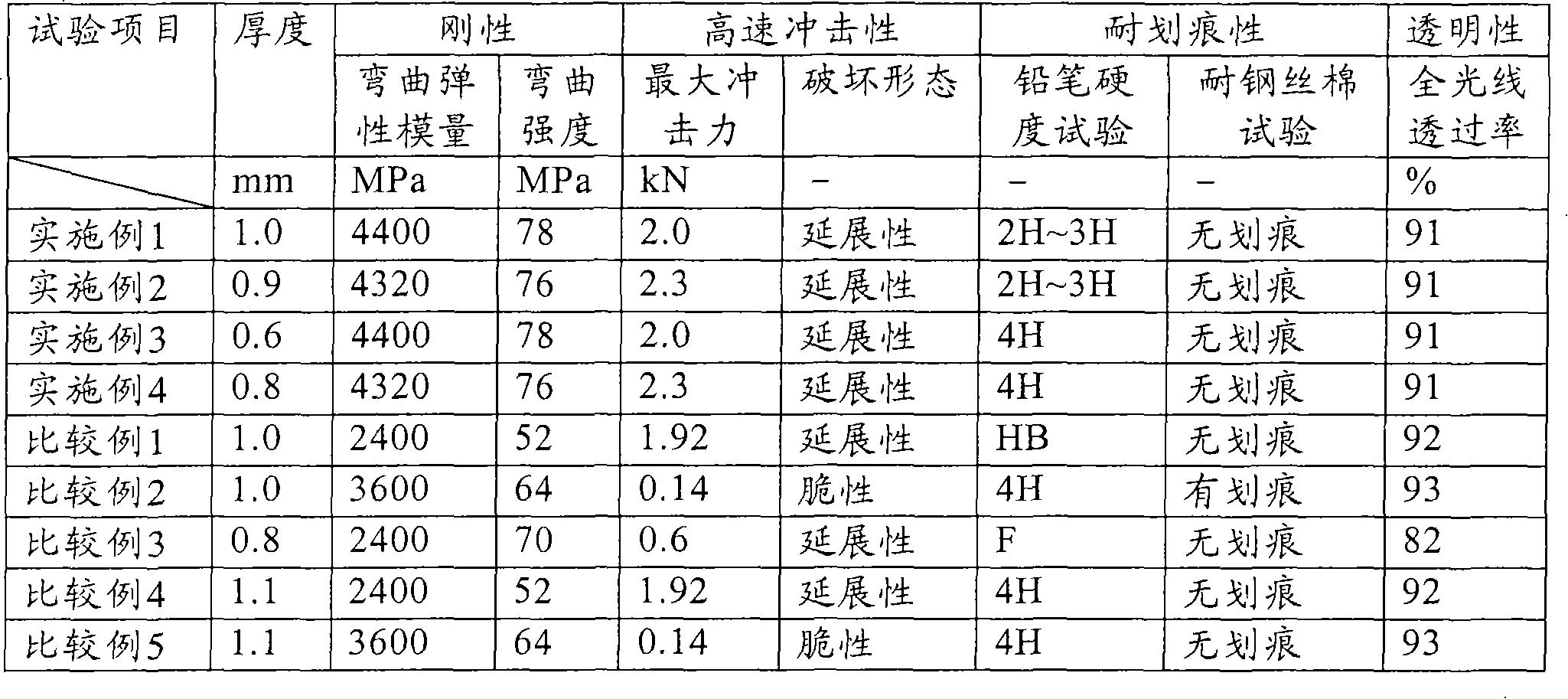

[0092] The same test as in Example 1 was performed on the obtained window material for a display, and the results shown in Table 1 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com