Method and apparatus for sealing polymer lithium ionic cell

A technology for lithium-ion batteries and sealing equipment, which is applied in the direction of secondary batteries, battery pack components, non-aqueous electrolyte storage batteries, etc. It can solve the problems of poor sealing effect product ratio, improve sealing performance, reduce gas swelling and leakage problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

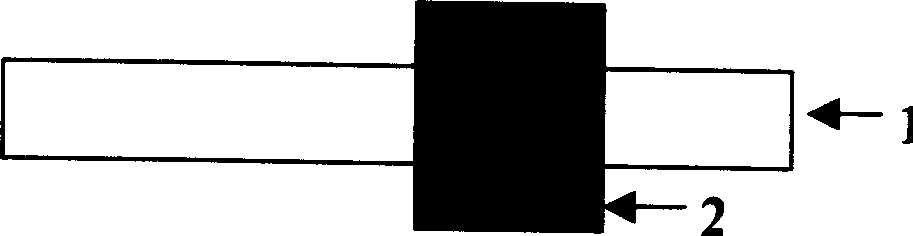

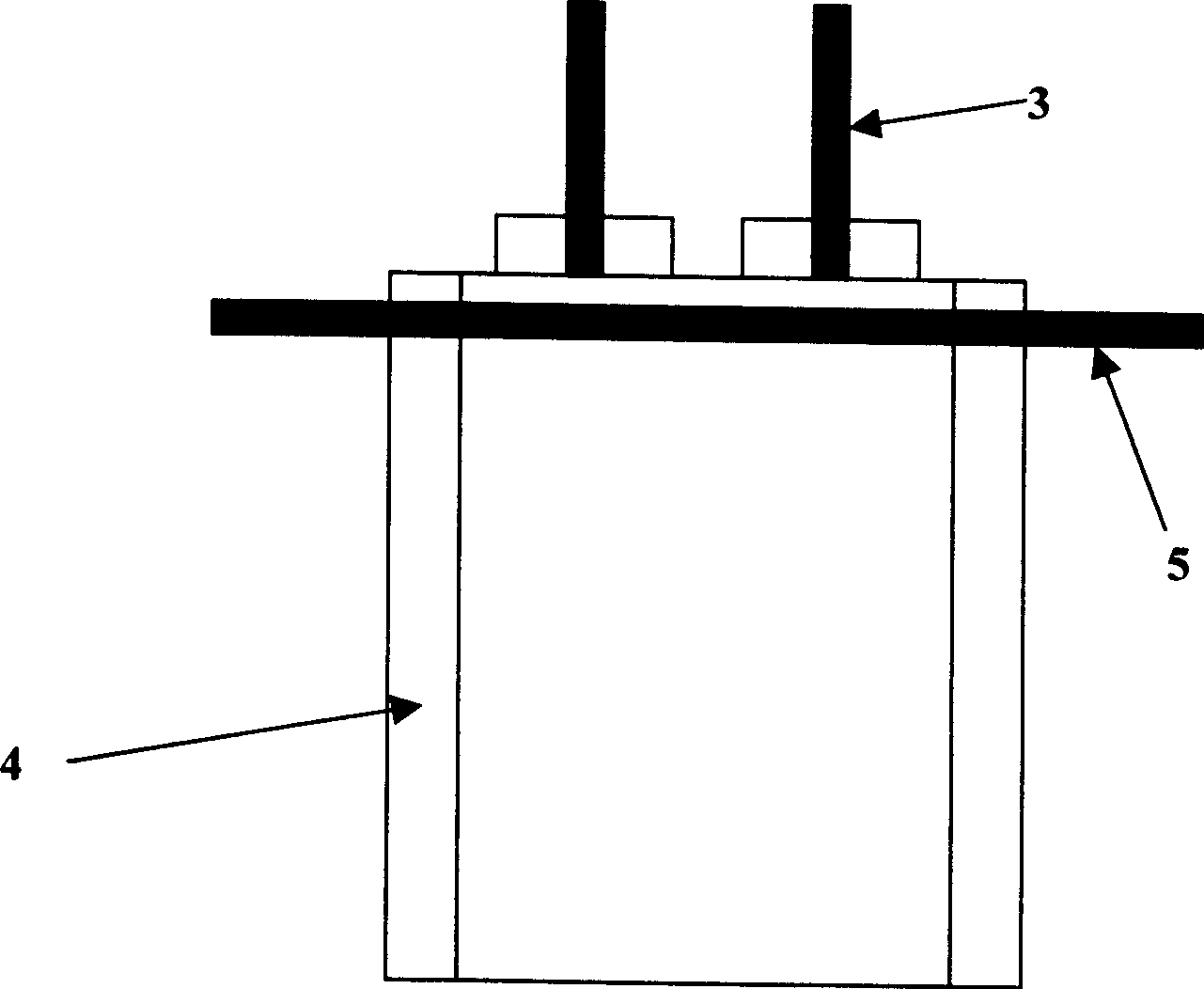

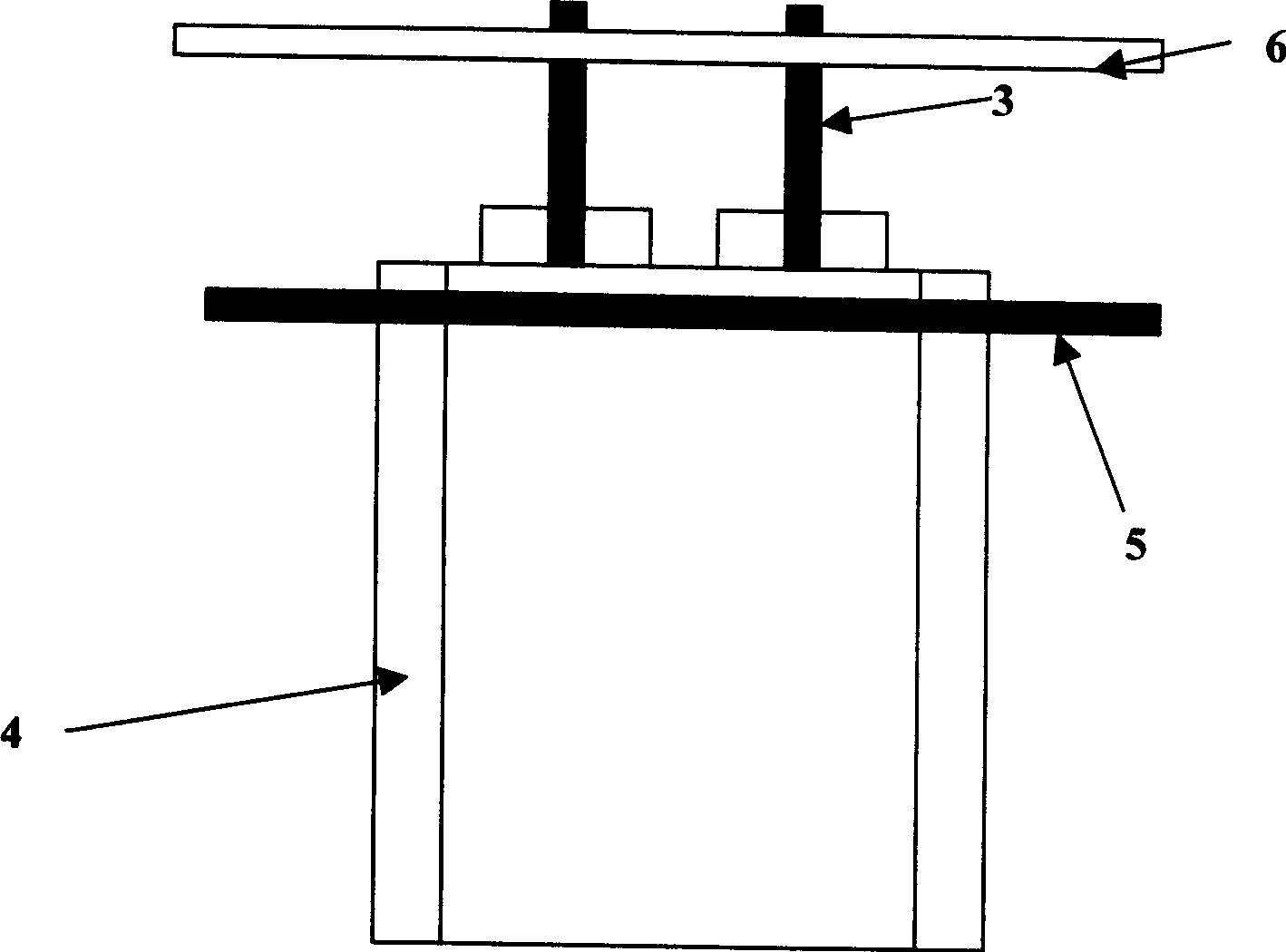

[0021] see image 3 , The invention provides a sealing method for a polymer lithium ion battery. It controls the heating temperature of the equipment to reach a stable value in a certain way, and heats the aluminum-plastic composite film 4 through two metal heating strips 5. The metal heating strips 5 are located on both sides of the battery, while maintaining a certain pressure, clamping the internal The aluminum-plastic composite film 4 of the fluid 3 acts for a period of time to conduct heat to the inside, so that the sealant 2 on the current collector 3 softens and melts, and releases the metal heating strip 5. After cooling, the sealant 2 seals the current collector 3 and Aluminum-plastic composite film 4 bonding. In such a process and equipment, the heat diffuses from the outside to the inside, and there is a temperature gradient. To make the temperature of the sealant reach the melting point, the aluminum-plastic composite film has to withstand a relatively higher temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com