Single-layer temperature difference part and integrated micro-temperature difference electric part made by film temperature different electric material

A technology of thin-film materials and electrical devices, which is applied in the field of single-layer thermoelectric devices and integrated micro-thermoelectric devices, can solve the problems of small size, low efficiency of thermoelectric devices, application limitations, etc., and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with accompanying drawing, the present invention is described in further detail:

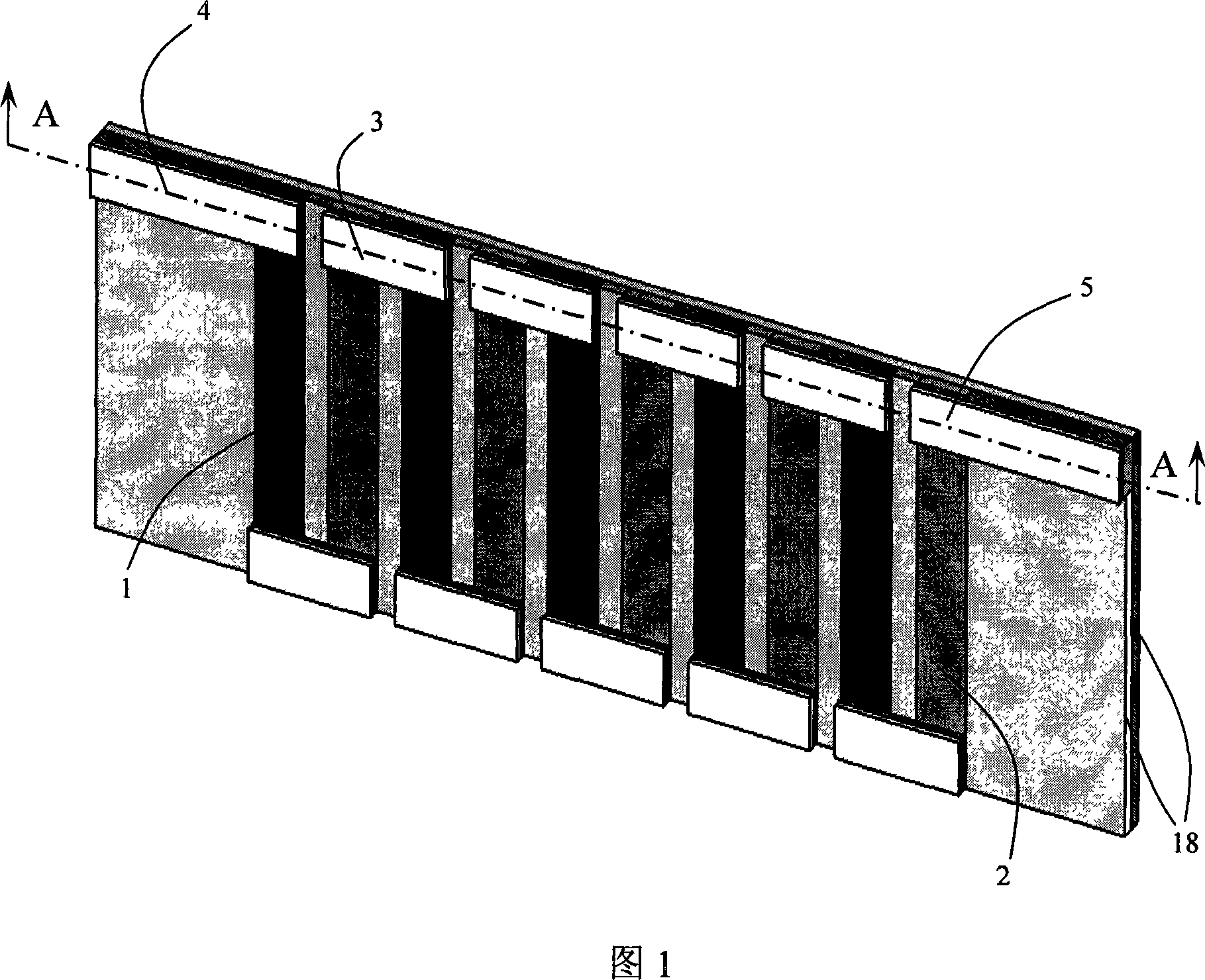

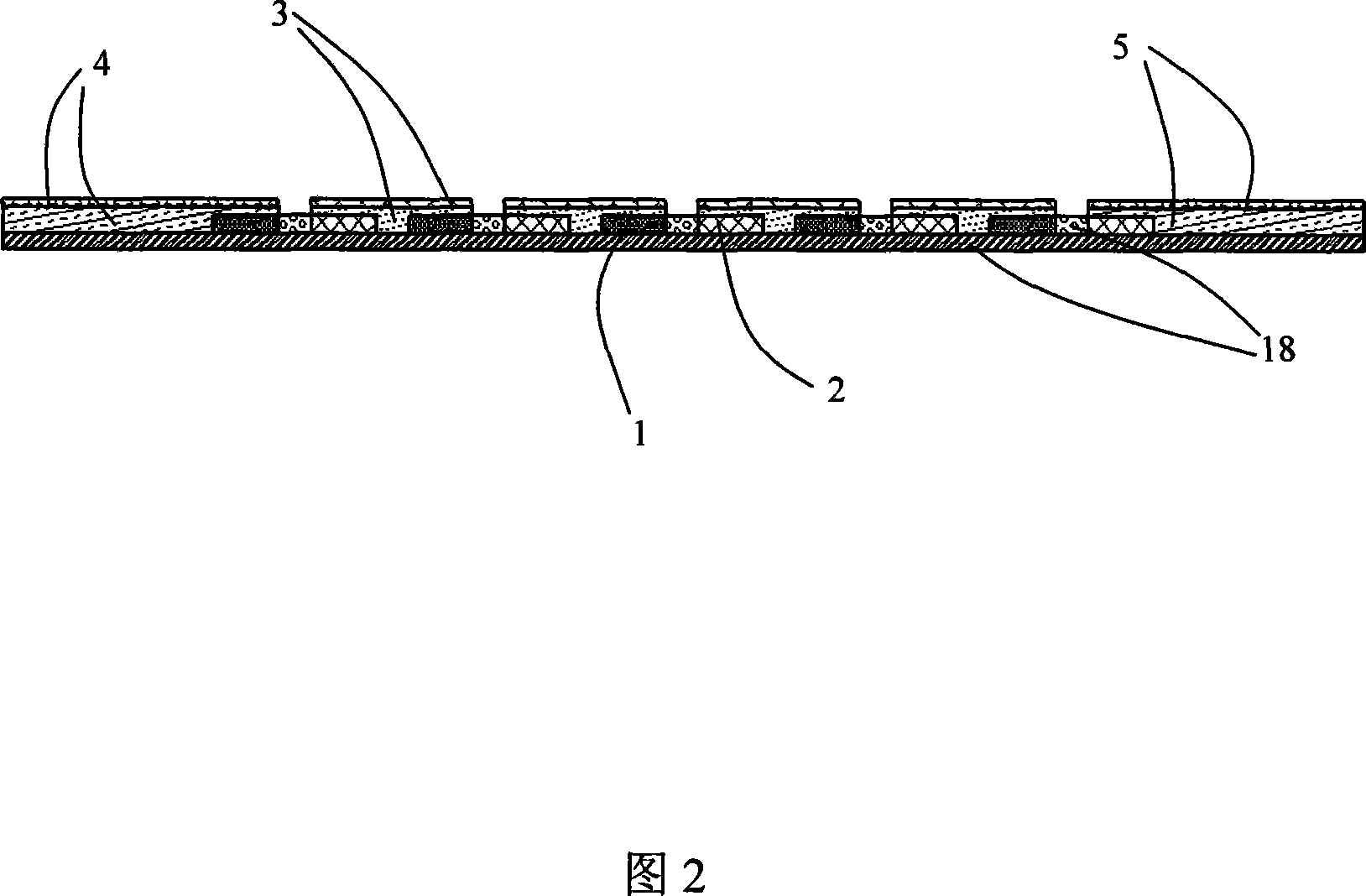

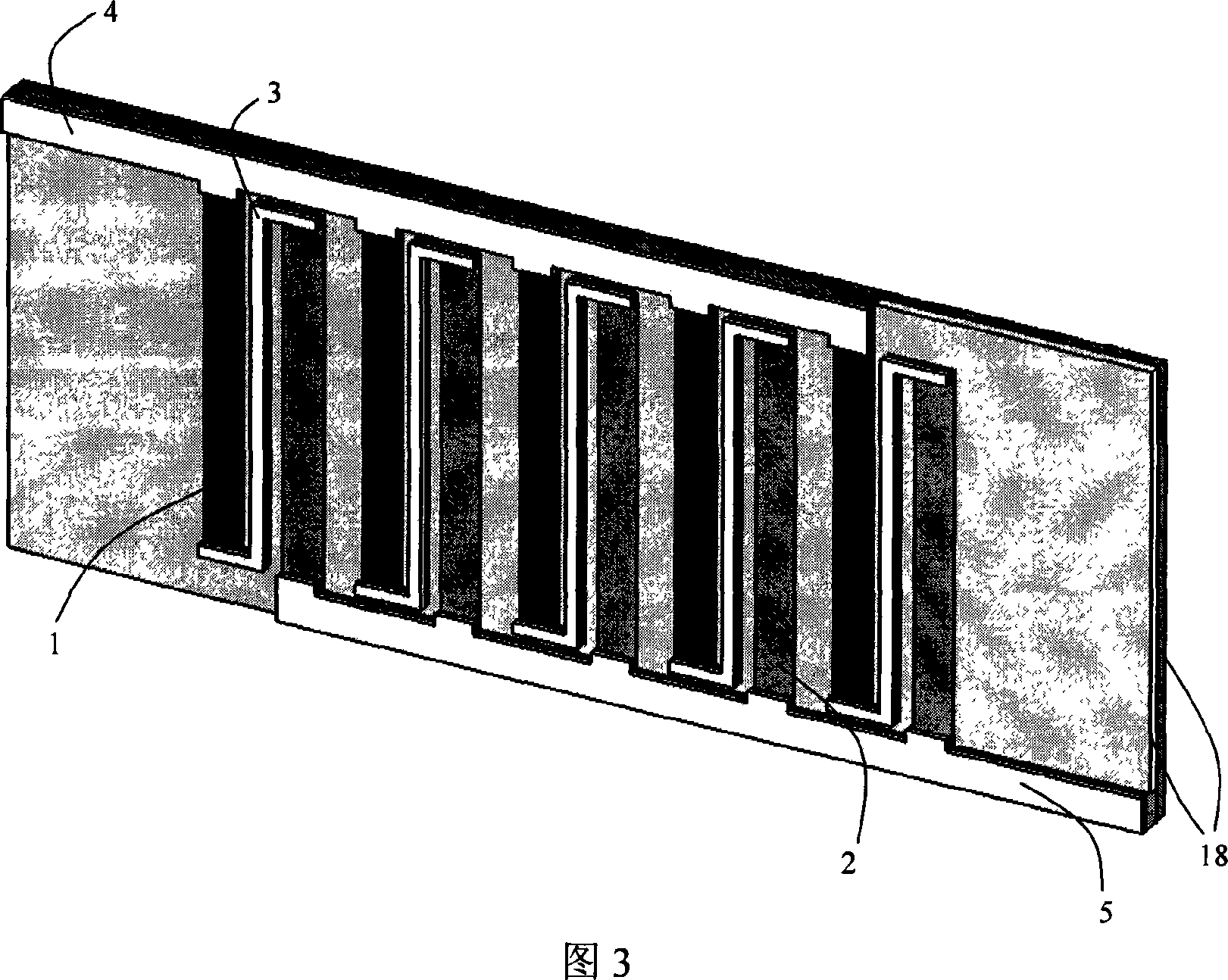

[0060]The single-layer thermoelectric device based on the thin-film thermoelectric material proposed by the present invention is formed by connecting a large number of P-type thermoelectric thin-film material monomers and N-type thermoelectric thin-film material monomers through electrical series or electrical parallel connection, with left and right The lug structure or the interconnecting lug structure is in the form of a film. The temperature differential of a single layer thermoelectric device is established along the length of a thin film of thermoelectric material. The three-dimensional structural diagram of a single-layer thermoelectric device with left and right tab structures formed by electrically connecting a P-type thermoelectric thin film material monomer and an N-type thermoelectric thin film material monomer is shown in Figure 1, and Figure 2 It is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com