Heat insulating building blocks and producing method

A technology of thermal insulation blocks and thermal insulation blocks, which is applied in the fields of building materials and thermal insulation blocks, can solve the problems of no consideration, products without thermal insulation performance, etc., and achieve the effects of cost saving, cold bridge effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take the thermal insulation block with a length of 410mm, a total width of 200mm, two sides, each width of 95mm, and a height of 200mm as an example:

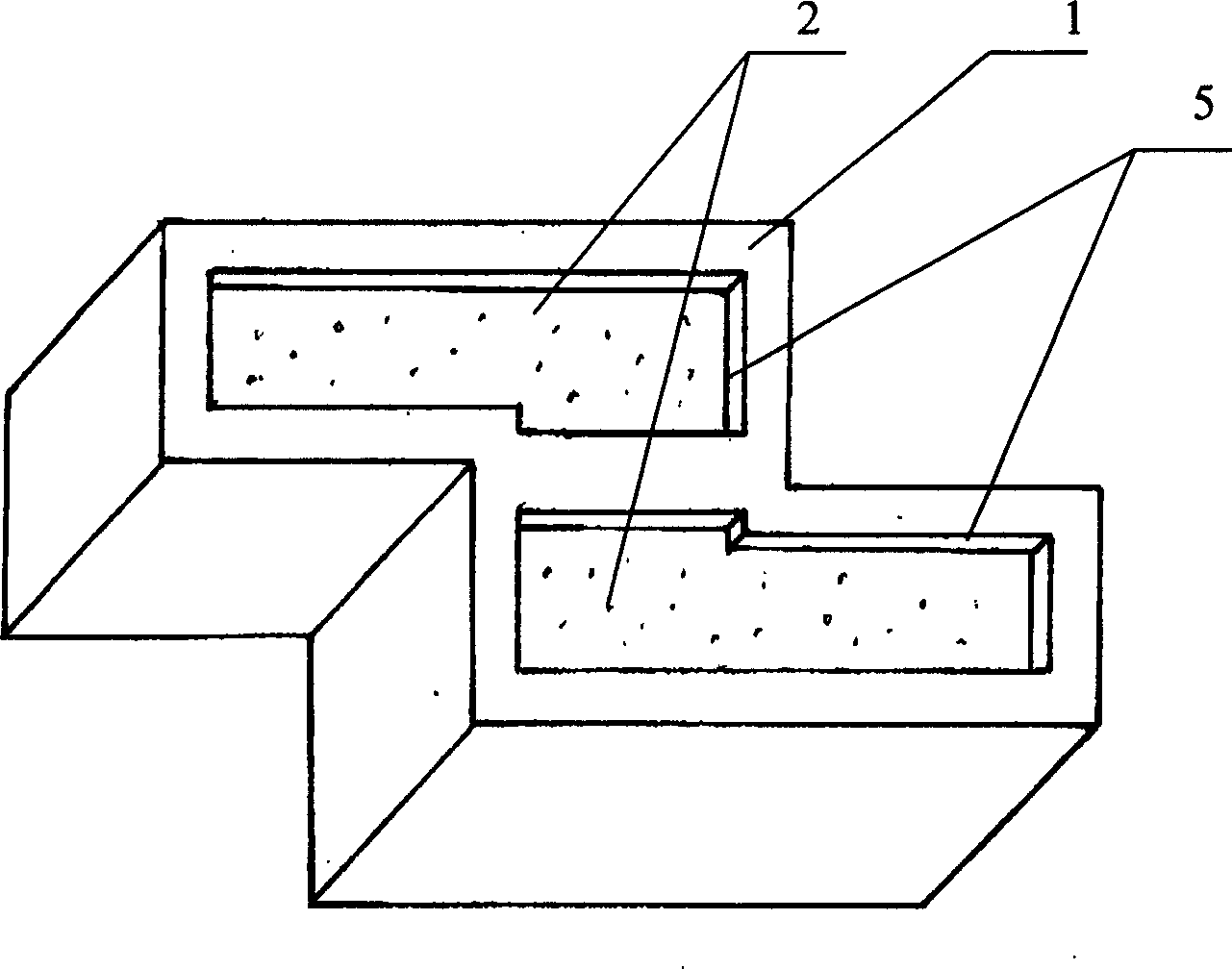

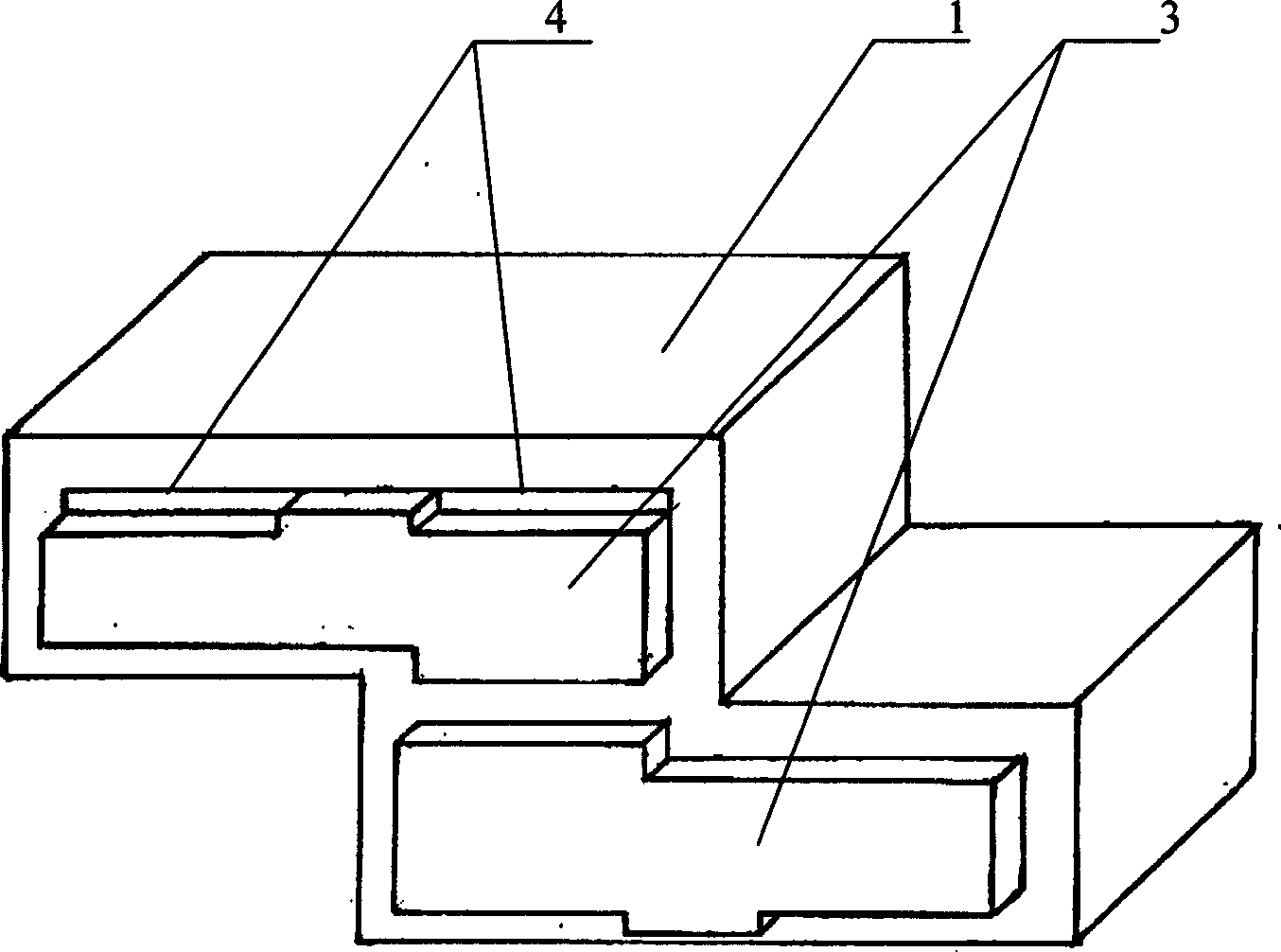

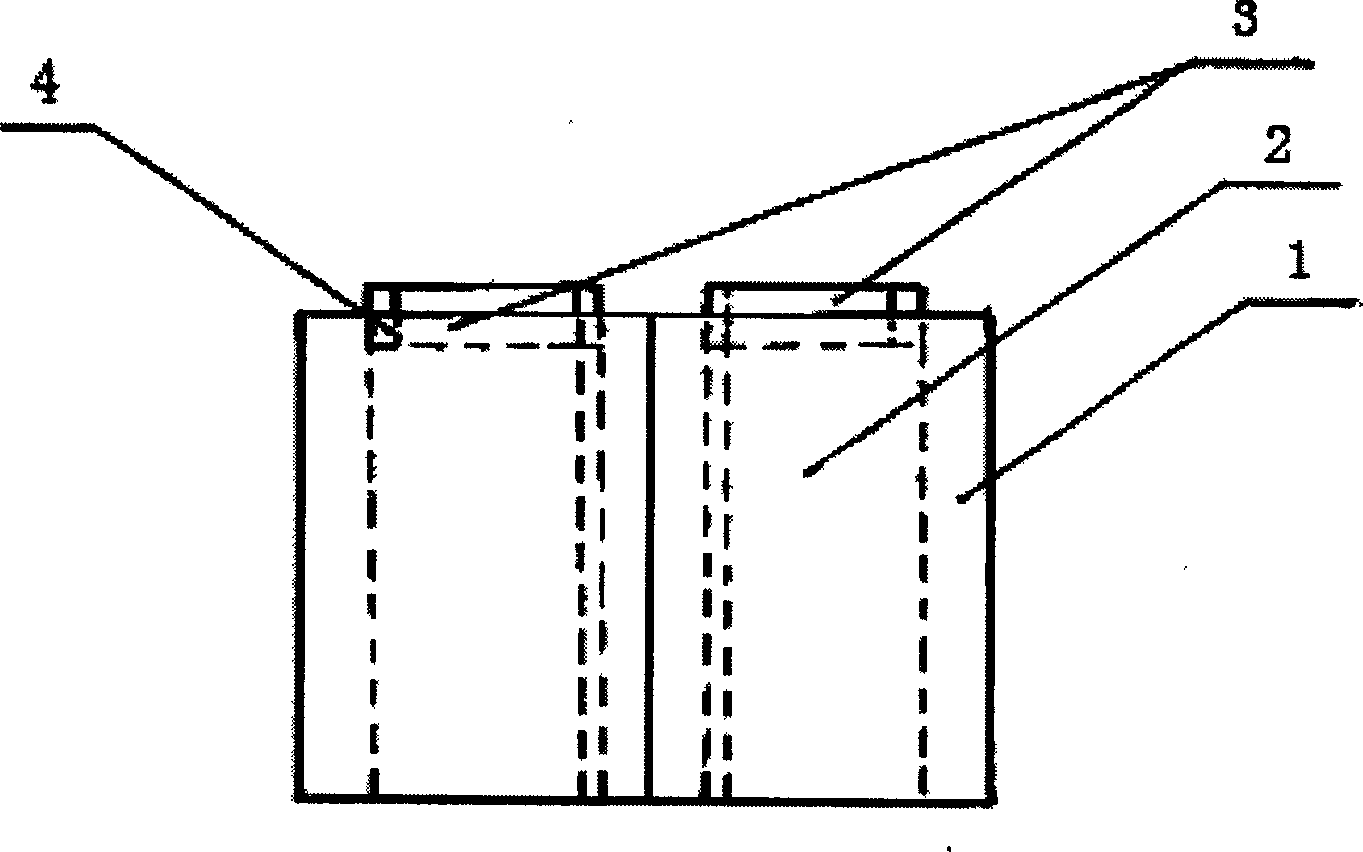

[0019] as attached figure 1 , 2 , 3 shows that the thermal insulation block is composed of a Z-shaped thermal insulation block shell 1 and a thermal insulation material core block 2. There is a dislocation through hole in the block, and the thermal insulation material core block 2 is filled in the through hole. When in use, it also includes Sheet-shaped insulation block 3; the upper surface of the insulation material core block 2 is 1 cm lower than the surface of the block. The thickness of the insulation block is 2cm, and the 1cm reserved space embedded in the block is reserved. At the same time, the upper surface of the sheet-like insulation block is in direct contact with the bottom end surface of the insulation block of the upper layer when the wall is built. The horizontal sand-ash joints are all isolated by insul...

Embodiment 2

[0023] The difference between this embodiment and embodiment 1 is, as figure 2 , 3 It is shown that the section shape of the sheet-like insulation block 3 is preferably designed to be convex, and grooves 4 are formed on the two sides of the protruding part. 5. Increase the connection strength between blocks. The material ratio of the Z-shaped thermal insulation block shell 1 is, by weight percentage, using 45% of clay ceramsite with a particle size of 8-15mm, 11% of cement as a binder, adding 44% of cinder, and stirring evenly Finally, use 20% water to vibrate and extrude in a Z-shaped mold.

[0024] The thermal insulation material core block is made of expanded perlite and industrial liquid sodium silicate, and then it is pressed and formed in the ceramsite block. The ratio of the expanded perlite and the industrial liquid sodium silicate is as follows: the expanded perlite accounts for 66% by weight, and the industrial liquid sodium silicate with a concentration of 20% a...

Embodiment 3

[0028]The difference between this embodiment and Embodiment 1 is that the material ratio of the Z-shaped heat-insulating block shell 1 is, by weight percentage, 40% of shale ceramsite with a particle size of 8-15mm, and 12% of cement. Adhesive, add 48% coal cinder, stir well and use 28% water to vibrate and extrude in Z-shaped mould.

[0029] The thermal insulation material core block is made of expanded perlite and industrial liquid sodium silicate, and then it is pressed and formed in the ceramsite block. The ratio of the expanded perlite and the industrial liquid sodium silicate is as follows: the expanded perlite accounts for 71% by weight, and the industrial liquid sodium silicate with a concentration of 35% accounts for 29%.

[0030] The sheet-like insulation block 3 adopts a formed polystyrene board, and its thickness is 30mm.

[0031] Production method is the same as embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com