A kind of heat insulation film and its preparation method and application

A heat-insulating film and heat-insulating material technology, applied in chemical instruments and methods, electrochemical generators, synthetic resin layered products, etc., can solve problems such as low structural strength and poor heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

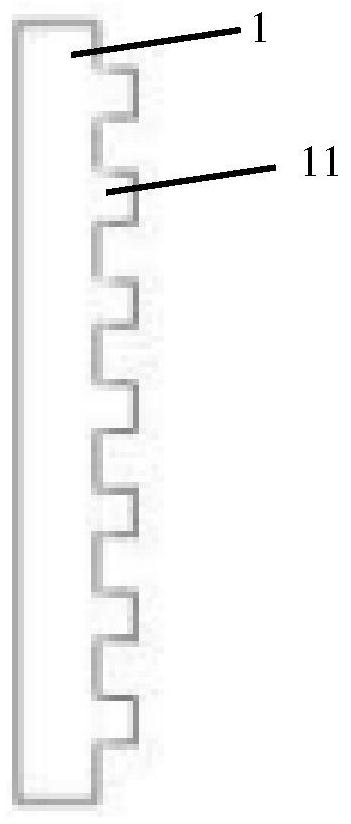

[0042] This embodiment provides a single-layer heat-insulating film, the structure of which is as follows: Figure 1A As shown, the single-layer heat insulating film 1 includes a raised structure 11, the raised structure 11 on the heat insulating film is 10 μm, and the contact area between the raised structure 11 and the adjacent heat insulating film accounts for 30% of the surface area of the heat insulating film; The thickness is 1mm.

[0043] The preparation method of the single-layer thermal insulation film of the present embodiment comprises the following steps:

[0044] (1) Use a ball mill to mix the following raw materials evenly:

[0045] 50% SiO 2 (D50 is 20nm, particle size distribution 5nm-70nm, 6808NM, SSNano), 20% ZrO 2 (D50 is 20nm, particle size distribution 5nm-70nm, 8512QI, SSNano), 10% SiC (D50 is 30μm, distribution is 5-50μm, 357391-250G, Sigma-Aldrich) and 20% glass fiber with a length of 3mm (T -786H, Nippon Electric Glass);

[0046] (2) Place the un...

Embodiment 2

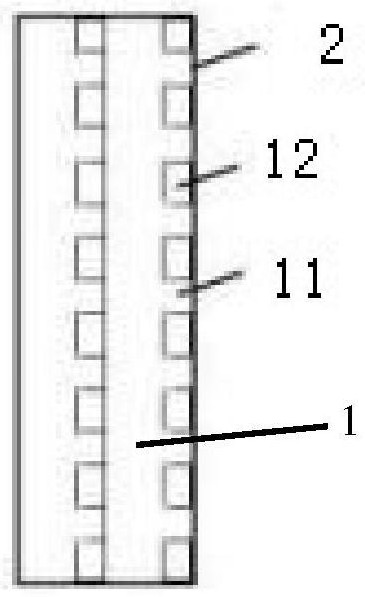

[0050] This embodiment provides a composite thermal insulation material, which includes two single-layer thermal insulation films, and the structure of the composite thermal insulation material is as follows: Figure 1B As shown, the composite heat insulation material includes two layers of single-layer heat insulation film 1, the single-layer heat insulation film 1 has a raised structure 11, the two layers of single-layer heat insulation film are wrapped by plastic sealing film 2, and the single-layer heat insulation film An air layer 12 is formed therebetween.

[0051] The preparation method of the composite thermal insulation film of the present embodiment comprises the following steps:

[0052] (1) Use a ball mill to mix the following raw materials evenly:

[0053] 50% SiO 2 (D50 is 20nm, particle size distribution 5nm-70nm, 6808NM, SSNano), 20% ZrO 2 (D50 is 20nm, particle size distribution 5nm-70nm, 8512QI, SSNano), 10% SiC (D50 is 30μm, distribution is 5-50μm, 357391...

Embodiment 3

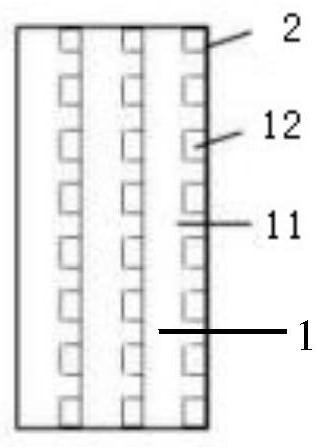

[0060] The composite heat insulation material provided in this embodiment includes three single-layer heat insulation films. The structure of composite insulation materials is as follows: Figure 1C As shown, it includes three pieces of single-layer heat insulation film 1, with a raised structure 11 on the single-layer heat insulation film 1, and the three pieces of single-layer heat insulation film are wrapped by plastic sealing film 2, and an air layer is formed between the three pieces of heat insulation film 12.

[0061] The preparation method of the composite thermal insulation film of the present embodiment comprises the following steps:

[0062] (1) Mix the following evenly with a ball mill:

[0063] 50% SiO 2 (D50 is 20nm, particle size distribution 5nm-70nm, 6808NM, SSNano), 20% ZrO 2 (D50 is 20nm, particle size distribution 5nm-70nm, 8512QI, SSNano), 10% SiC (D50 is 30μm, distribution is 5-50μm, 357391-250G, Sigma-Aldrich) and 20% glass fiber with a length of 3mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com