Production of color-sensitive gas sensor array

A technology of gas sensor and manufacturing method, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by causing chemical reaction of materials, etc., can solve problems such as poor repeatability and short service life, and achieve consistency improvement. , the effect of prolonging the service life and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

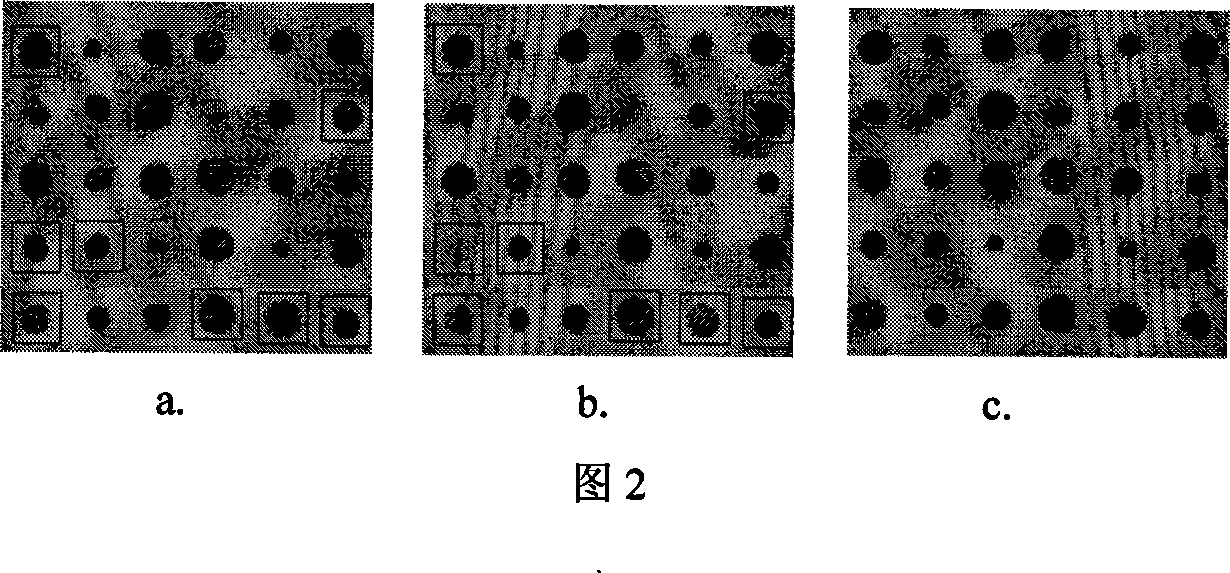

[0019] The color-sensitive gas sensor array manufacturing method of the present invention will be described in more detail below in conjunction with the accompanying drawings:

[0020] (1) Selection of gas color-sensitive materials: Select those hydrophobic porphyrin compounds and acid-base indicators that have color changes to gases as sensor materials. After many tests, porphyrin compounds such as protoporphyrin, zinc porphyrin, iron porphyrin, tin porphyrin, copper porphyrin and hydrophobic acid-base indicators such as methyl red and methyl blue were finally selected.

[0021] (2) Selection of solvent: select p-chlorotoluene as the solvent of the porphyrin compound, and alcohol as the solvent of the hydrophobic acid-base indicator, and dissolve them in the solvent at a concentration of 1 mol / L to form respective solutions.

[0022] (3) Selection and production of sensor base materials: ①Choose food-grade white polytetrafluoroethylene as the base plate 1, first process the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com