Method for preparing single dispersing ball-shape mesoporous titanium dioxide colloid particles whose size and apparance are controllable

A technology of mesoporous titanium dioxide and colloidal particles, which is applied in the treatment of titanium dioxide, titanium oxide/hydroxide, and dyed polymer organic compounds, can solve the problems of difficult control of shape and size, complexity and time-consuming, and poor monodispersity of particles. Easy to popularize and apply, cheap solvent, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

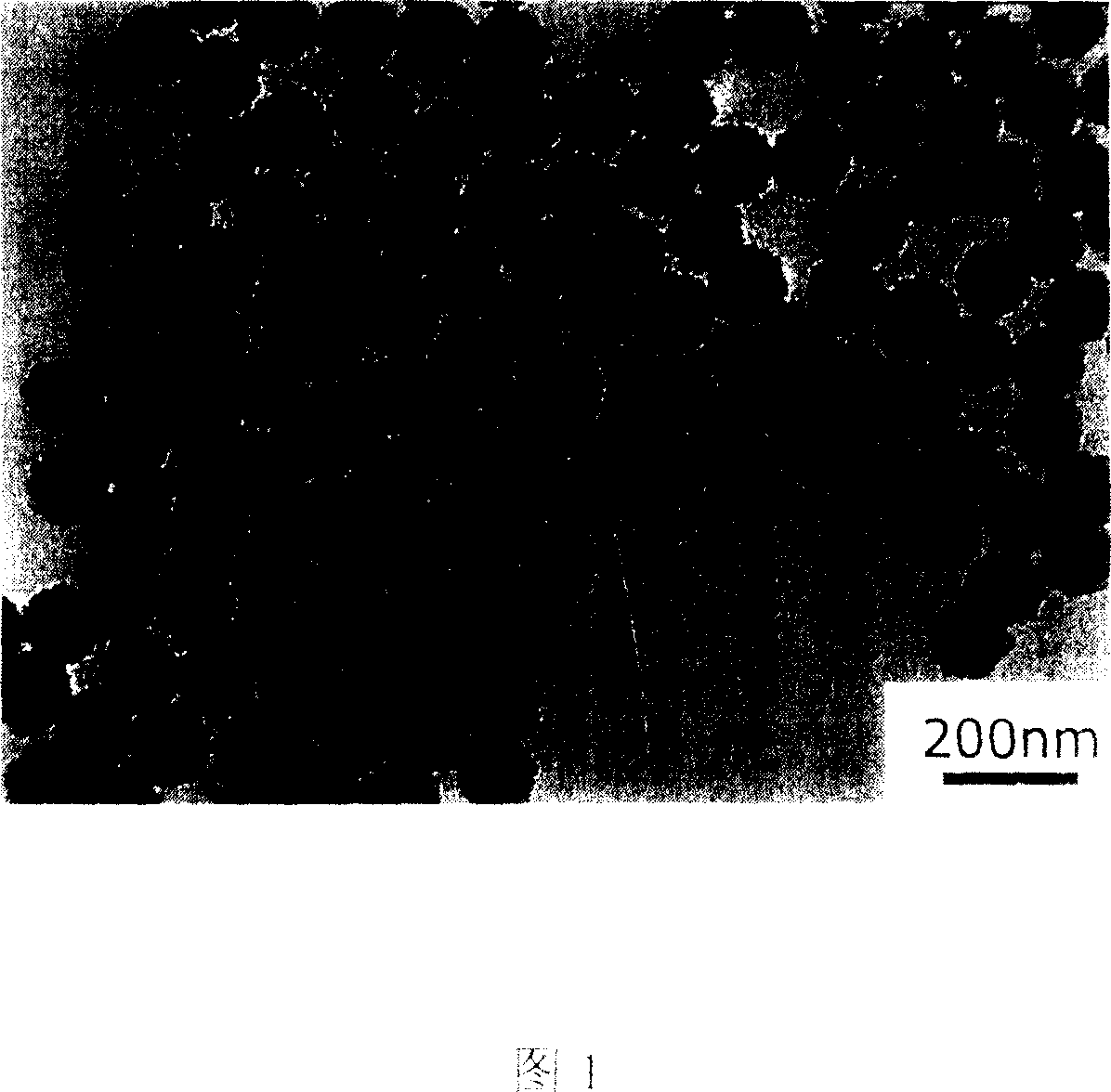

Image

Examples

Embodiment 1

[0031] (1) absolute ethanol and acetonitrile are mixed uniformly in a volume ratio of 1:2;

[0032] (2) Dissolve tetrabutyl titanate in the mixed solvent obtained in step (1), and stir evenly, wherein the initial concentration of tetrabutyl titanate is 2×10 -3 mole / liter;

[0033] (3) ammoniacal liquor is added in the mixed solvent of step (1) gained, stir, then add a certain amount of commercially available diameter and be the PSMMA ball of 220nm to disperse evenly, wherein the initial concentration of ammonia is 0.1 mol / liter, PSMMA ball The initial concentration of 0.02 g / L;

[0034] (4) At room temperature, the solution prepared in step (3) is added to the reactor, and then the tetrabutyl titanate mixed solvent solution prepared in step (2) is added to the reactor, wherein step (2) and Step (3) The volume ratio of the solution is 1:2, and the reaction is stirred for 12 hours to obtain a milky white or white turbid liquid, which is centrifuged to obtain colloidal particle...

Embodiment 2

[0038] (1) absolute ethanol and acetone are mixed uniformly in a volume ratio of 10:3;

[0039] (2) Dissolve tetrabutyl titanate in the mixed solvent obtained in step (1), and stir evenly, wherein the initial concentration of tetrabutyl titanate is 5×10 -4 mole / liter;

[0040] (3) ammoniacal liquor is added in the mixed solvent of step (1) gained, stir, then add a certain amount of diameter and be the PSMMA ball of 260nm and disperse evenly, wherein the initial concentration of ammonia is 0.06 mol / liter, the initial concentration of PSMMA ball 0.012 g / L;

[0041] (4) Add the solution prepared in step (3) into the reactor at room temperature (25-30°C), and then add the tetrabutyl titanate mixed solvent solution prepared in step (2) into the reactor, Wherein the volume ratio of step (2) to step (3) solution is 3: 2, stirring and reacting for 2 hours, milky white or white turbid liquid is obtained, centrifuged to obtain styrene-methacrylic acid copolymer microsphere surface coa...

Embodiment 3

[0045] (1) absolute ethanol and acetonitrile are mixed uniformly in a volume ratio of 1:13;

[0046] (2) Dissolve tetraisopropyl titanate in the mixed solvent obtained in step (1), and stir evenly, wherein the initial concentration of tetraisopropyl titanate is 2.5×10 -2 mole / liter;

[0047] (3) water is added in the mixed solvent of step (1) gained, stir well, then add the PSMMA ball that a certain amount of self-made diameter is 350nm and disperse evenly, wherein the initial concentration of water is 0.1 mol / liter, the PSMMA ball's The initial concentration is 0.025 g / L;

[0048] (4) At room temperature, add the solution prepared in step (3) into the reactor, and then add the tetraisopropyl titanate mixed solvent solution prepared in step (2) into the reactor, wherein step (2) The volume ratio to the solution in step (3) is 4:1, and the reaction is stirred for 3 hours to obtain a milky white or white turbid liquid, which is centrifuged to obtain colloidal particles of styr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com