Composition for dip forming and dip-formed molding

A technology of dip molding and composition, applied in the direction of coating, can solve problems such as poor bending fatigue resistance and cracking, and achieve the effects of low surface resistivity, excellent tensile strength and bending fatigue resistance, and excellent hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

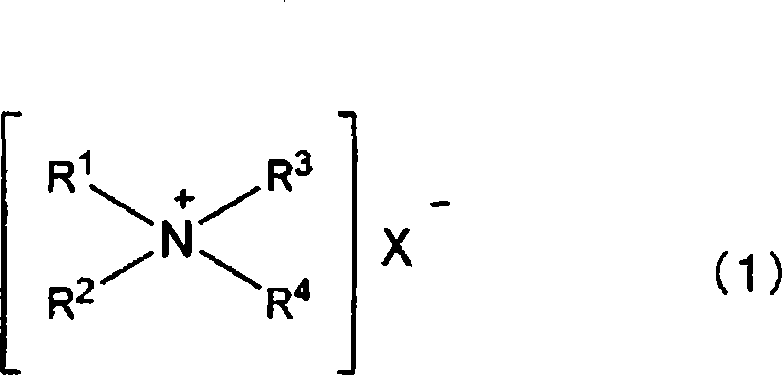

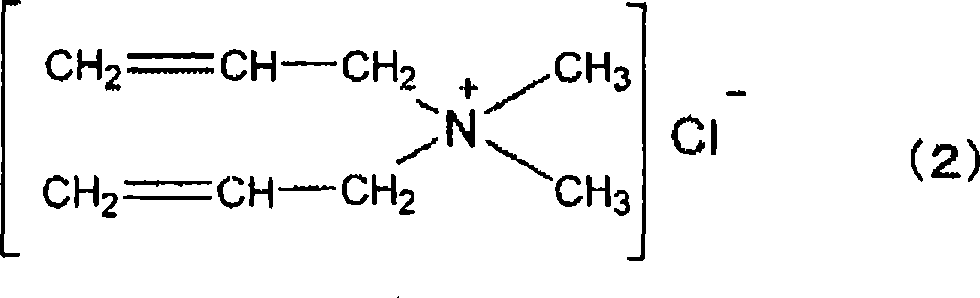

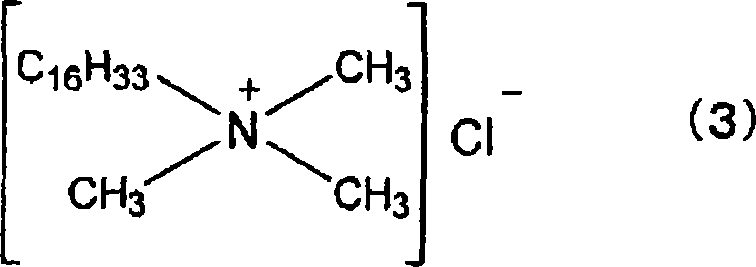

Method used

Image

Examples

preparation example Construction

[0087] The preparation method of the composition of the present invention is: dispersing the organic peroxide in the water medium in the presence of the surfactant and the water-soluble polymer to prepare the dispersion liquid, adding and mixing it in the conjugated diene rubber latex. This dispersion liquid is preferably added to the conjugated diene rubber latex in a stirred state.

[0088] In addition, when the composition of the present invention contains the above-mentioned quaternary ammonium salt, the method for preparing the composition of the present invention is preferably a method of adding and mixing an aqueous solution of a quaternary ammonium salt to a conjugated diene rubber latex to prepare a latex to which a quaternary ammonium salt is added. In addition, use surfactant and / or polymer protective colloid to disperse organic peroxide in water medium to prepare organic peroxide dispersion water, add and mix above-mentioned organic peroxide dispersion water in the ...

Embodiment

[0118] Hereafter, although an Example and a comparative example are given and this invention is demonstrated more concretely, this invention is not limited to these Examples. In addition, unless otherwise specified, the parts in these examples are based on weight. The test and evaluation are as follows.

[0119] (1) Gel increase rate

[0120] A sample cut out to an approximately 5 mm square from the obtained rubber glove was precisely weighed. This was placed in an 80-mesh JIS standard sieve, and immersed in 80 ml of methyl ethyl ketone (MEK) for 24 hours. The sieve was removed from the MEK, air dried for 1 hour and then dried at 105°C for 1 hour. The gel was weighed again with a sieve, and the ratio (% by weight) to the original sample was determined from the weight of the gel portion held on the sieve, and it was defined as the gel content. Next, this value was compared with the value in Comparative Example 1 (when no organic peroxide was added) to obtain the rate of inc...

preparation example 1

[0133] (preparation example 1: the preparation of carboxyl modified NBR latex)

[0134]Add 28 parts of acrylonitrile, 66 parts of 1,3-butadiene, 6 parts of methacrylic acid, 0.3 parts of tert-dodecyl mercaptan, 132 parts of ion-exchanged water, dodecylbenzenesulfonic acid 3 parts of sodium, 0.5 part of β-naphthalenesulfonic acid formaldehyde condensate sodium salt, 0.3 part of potassium persulfate, and 0.05 part of sodium ethylenediaminetetraacetate. The polymerization temperature was maintained at 37°C to start polymerization.

[0135] When the polymerization conversion rate reaches 60%, add 0.15 parts of tert-dodecyl mercaptan, and the polymerization temperature is raised to 40° C., then, when the polymerization conversion rate reaches 80%, add 0.15 parts of tert-dodecyl mercaptan to continue polymerization reaction until the polymerization conversion rate reaches 94%. Then, 0.1 part of sodium dimethyldithiocarbamate was added as a polymerization terminator to terminate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com