Biological cycle moving bed sewage treatment system and method thereof

A sewage treatment system and biological cycle technology, applied in the direction of biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problem of biofilm staged effluent water quality deterioration and poor fluid mixing performance , increase operating costs and other issues, to achieve the effect of reasonable structure, good fluid mixing performance, and prevent the loss of carrier filler

Inactive Publication Date: 2007-10-31

张文虎

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] The purpose of the present invention is to provide a biological circulating moving bed sewage treatment system and its method, which mainly solves the phenomenon of stratification after the thickening of the biofilm and the lightening of the carrier particles in the traditional biological fluidized bed, and the special film removal device will greatly increase the The problem of operating costs; at the same time, after a period of operation of the traditional biological fluidized bed reactor, due to the excessive thickness and shedding of the biofilm, the technical problems of staged effluent water quality, low efficiency, and poor fluid mixing performance will be solved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0065] The proportioning embodiment 1 of above-mentioned inert carrier filler by weight is as follows:

[0066] 100 parts of waste rubber powder;

[0067] 20-30 parts of polyurethane;

[0068] 10-20 parts of kaolin.

Embodiment 2

[0069] The proportioning embodiment two of above-mentioned inert carrier filler by weight is as follows:

[0070] 100 parts of waste rubber powder;

[0071] 25 parts of polyurethane;

[0072] Kaolin 15 parts.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Login to View More

Abstract

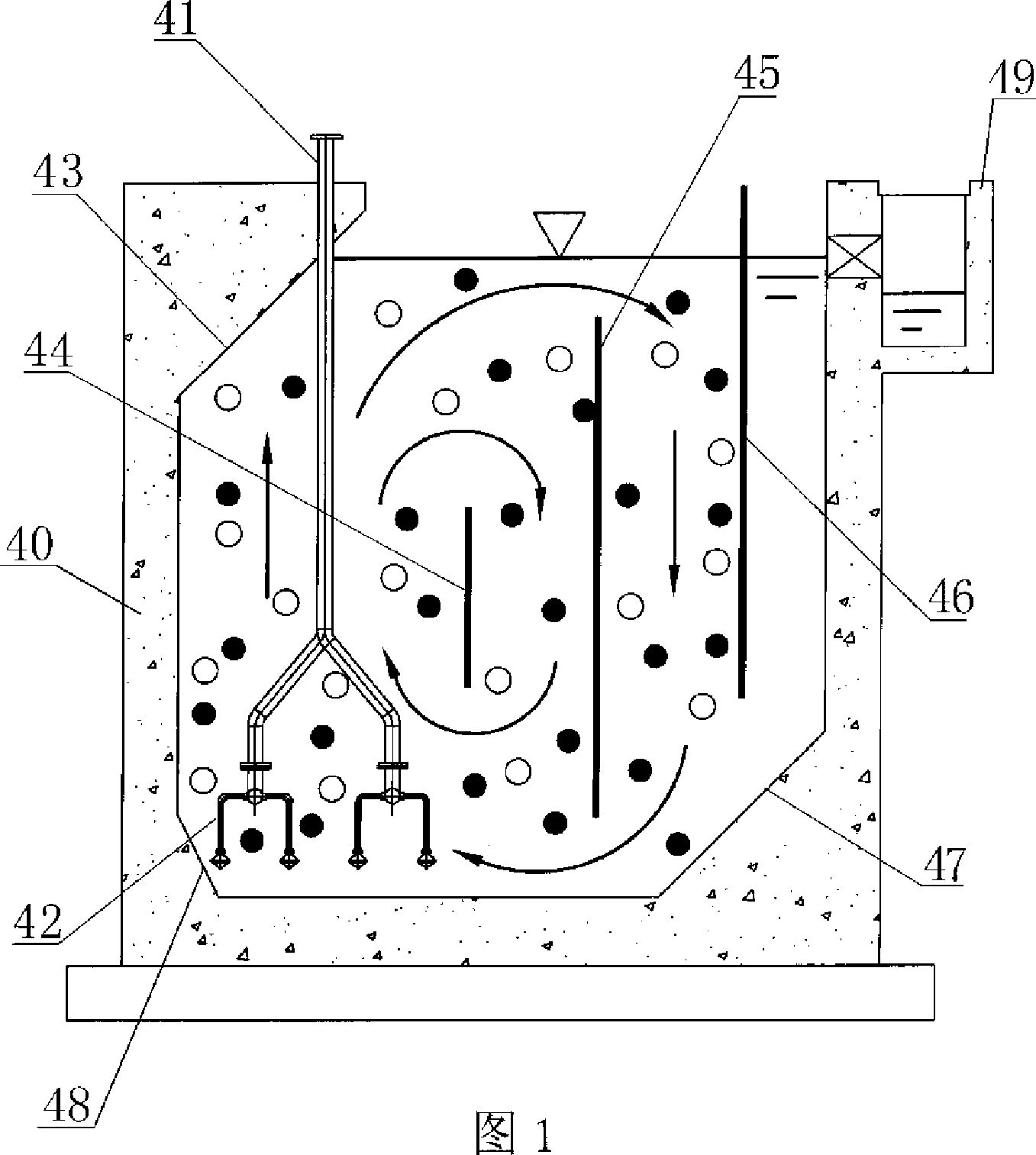

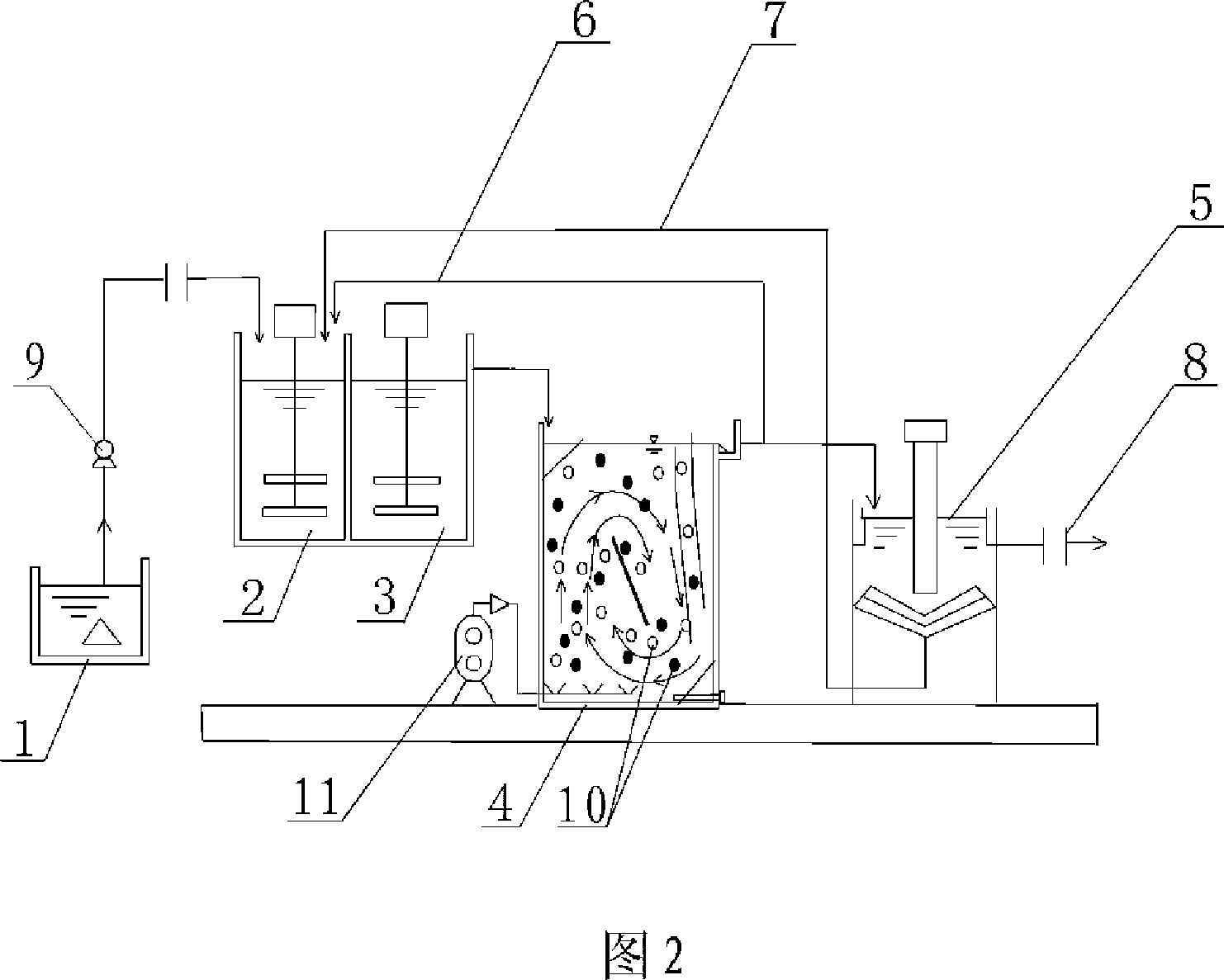

The invention discloses a biological cycle moving bed sewage disposal system and method, which comprises the following steps: entering the raw water into anoxybiotic tank and anaerobic tank with pump from raw water tank; treating; feeding into the cycle moving bed reactor to proceed aeration oxygenation reaction; making the inner section in the tank body of current, inert support filler and bubble be directed with up-and-down cycle splitter, separating splitter and tailboard; forming circulatory flow; reacting the microbe of the current and the inert support filler completely; discharging into desilter; refluxing the depositing sludge in the bottom of the desilter into the anoxia tank; discharging the clear water in the upper of the desilter from the exhaust pipe; refluxing the treated water in the reactor into the anoxia tank through internal reflux pipe. This invention avoids the stratification, which can decrease the operating expense.

Description

(1) Technical field [0001] The invention relates to a sewage treatment system and its method, in particular to a biological fluidized bed sewage treatment system and its method. (2) Background technology [0002] The traditional biological fluidized bed sewage treatment system is composed of raw water tank, anoxic tank, anaerobic tank, fluidized bed reactor and sedimentation tank connected in sequence. The circulating moving bed reactor is a rectangular pool body for sewage reaction, and the pool body is connected with an aerator. There are following defects in the operation process: the biofilm in the biological fluidized bed will gradually thicken, and the carrier particles will gradually become lighter, so that stratification occurs in the fluidized bed, and a special film removal device needs to be configured, which greatly increases operating costs. What's more, after a period of operation of the traditional fluidized bed reactor, due to the shedding of the overly thi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F3/02C02F3/10C02F3/30

CPCY02W10/10

Inventor 张文虎

Owner 张文虎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com