Novel crystallizer for preparing alkali

A crystallizer, a new type of technology, applied in the direction of solution crystallization, etc., can solve the problems of high crystallizer temperature, alkali stop to cool down, unable to hydrate and crystallize, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

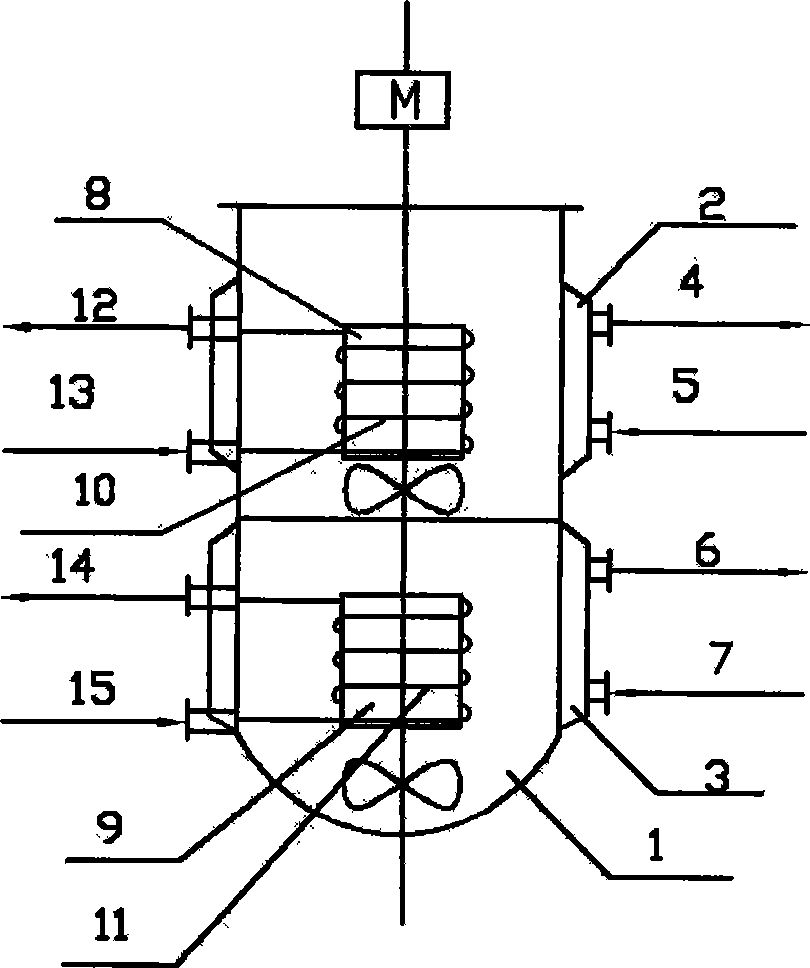

[0007] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0008] As shown in the figure, a new type of crystallizer for soda production includes a tank body 1, upper and lower jackets 2 and 3 wrapped on the outer wall of the tank, and the upper and lower jackets are respectively equipped with inlet and outlet The water outlets 4, 5, 6, 7, the upper and lower guide tubes 8, 9 are arranged in the tank body 1, and the outer walls of the upper and lower guide tubes are respectively wound with upper and lower heat conduction tubes The coiled tubes 10, 11, the upper heat conduction tube coil has water inlet and outlet ports 12, 13 arranged on the tank body, and the lower heat transfer tube coil tube has water inlet and outlet ports 14, 15 arranged on the tank body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com